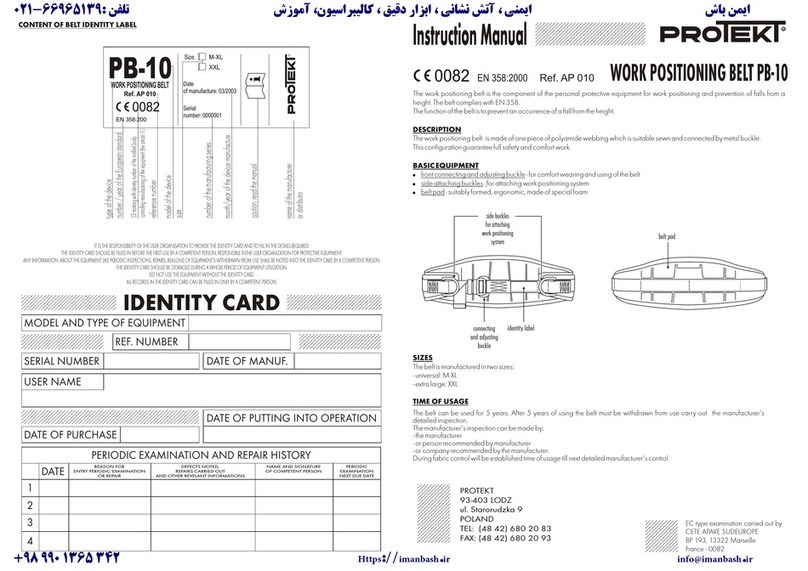

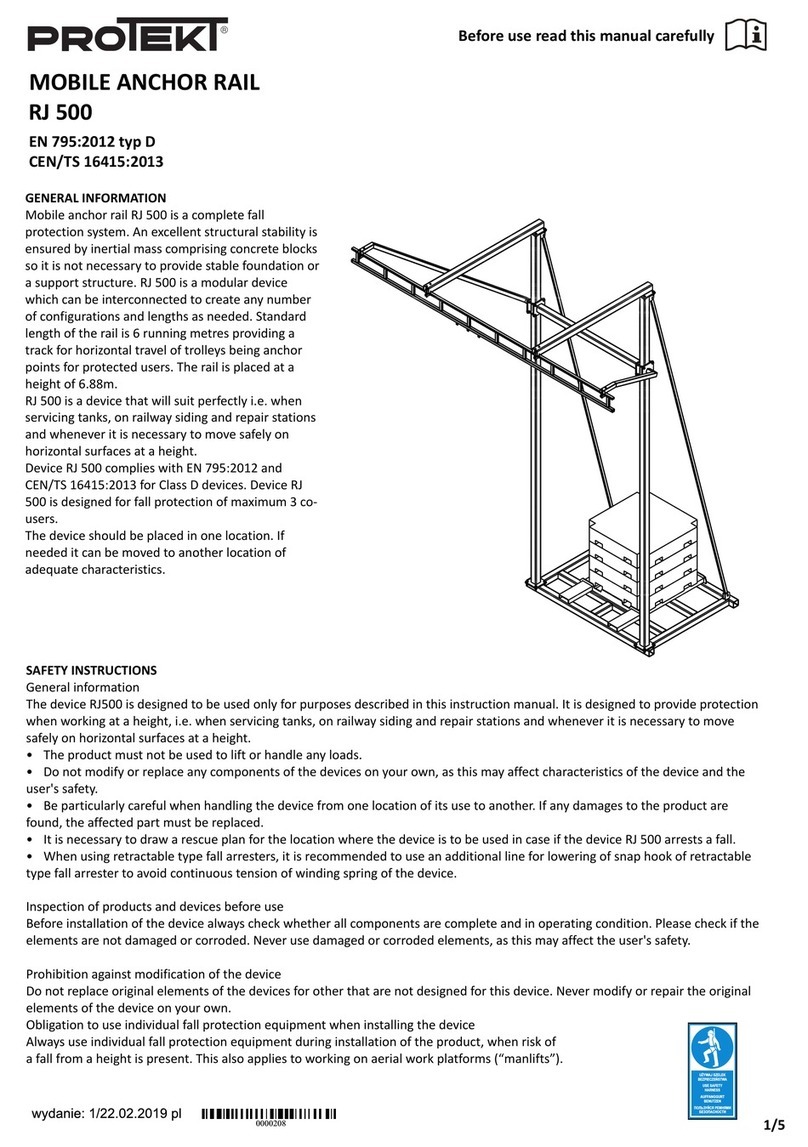

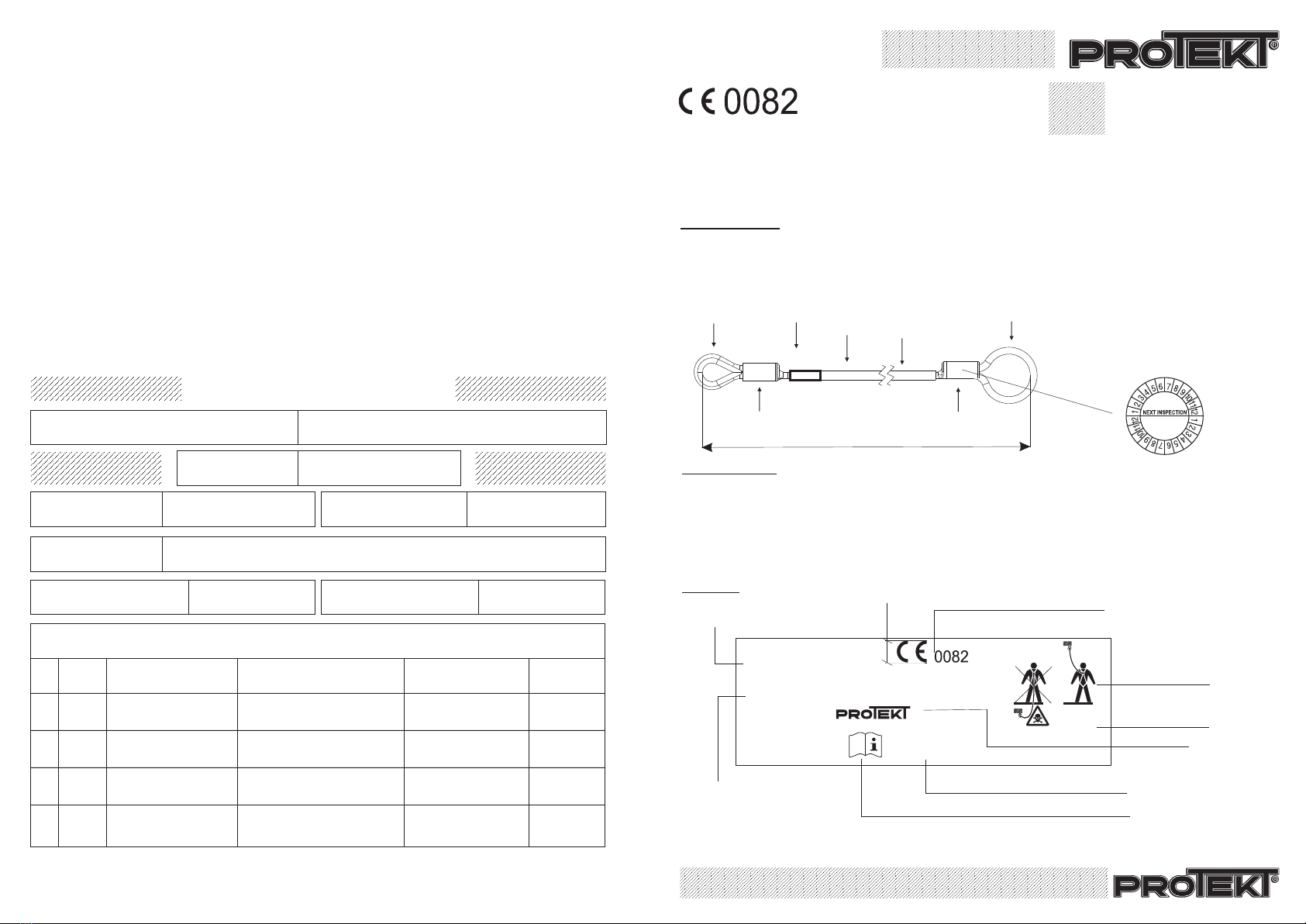

ATTACHINGANCHOR DEVICEAT191

AB

CDE

ATTENTION:

Anchror device

AT191 shall not be

used alone as a fall

arrest device.

The structural anchor

point should be situated

above the working

place and the shape of

the structural anchor

point should not let self-

acting disconection of

the lanyard. Minimal

static strength of

structural anchor point

shall be 30 kN.

X

Attention!

always work with a locked

connector protected by

tightening up a nut

LINAROBOCZA

USPBLOCMAX-RORIP

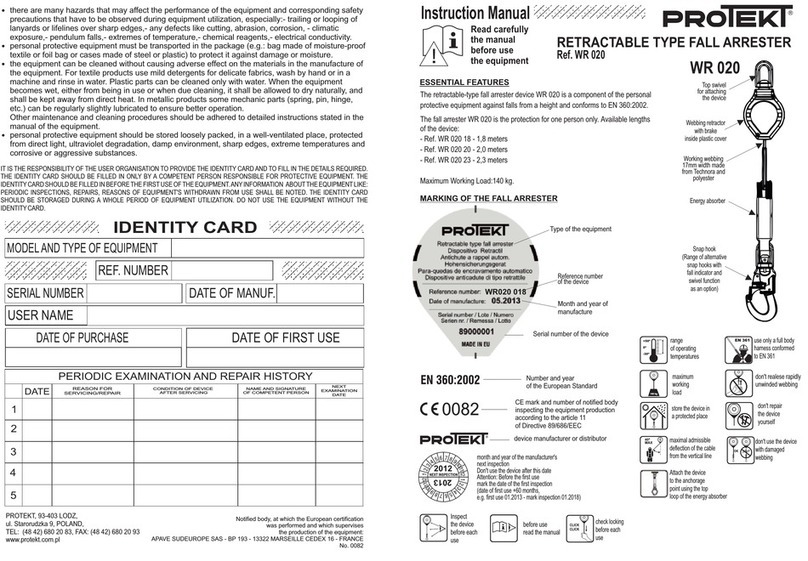

*personal protective equipment shall only be used by a person trained and competent in its safe use.

*

emergency use.

*a rescue plan shall be in place to deal with any emergencies that could arise during the work.

*it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

*any repair shall only be carried out by equipment manufacturer or his certified representative.

*personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

*personal protective equipment should be a personal issue item.

*before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the

equipment components to avoid accidental loosening or disconnecting of the components.

*it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of

another.

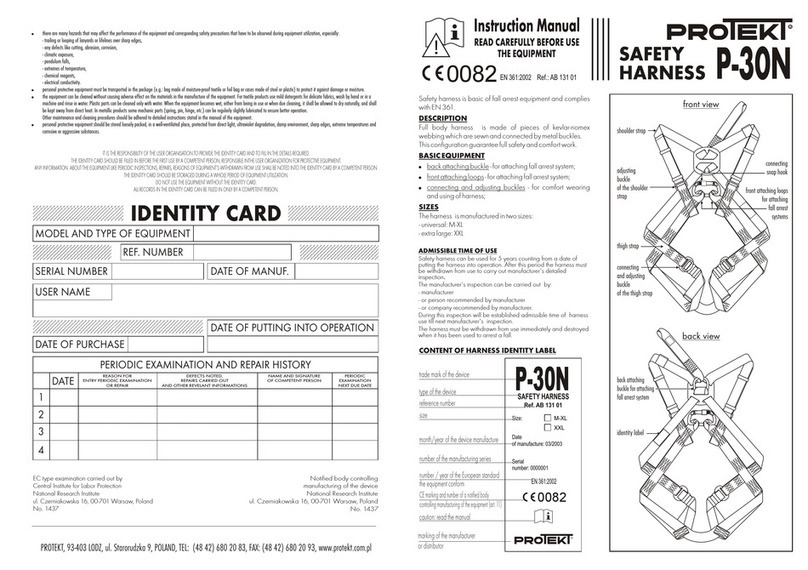

*before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition

and operates correctly before it is used.

*during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or

incorrect acting, especially take into consideration:

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in connectors - main body, rivets, gate, locking gear acting.

*after every12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic

inspection must be carried out by

a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

*In case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the

manufacturer or his authorized representative.

*regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and

durability of the equipment.

*during periodic inspection it is necessary to check the legibility of the equipment marking.

*it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

*personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until

confirmed in writing by equipment manufacturer or his representative after carried out the detailed inspection.

*personal protective equipment must be withdrawn from use immediately and destroyed when it have been used to arrest a fall.

,

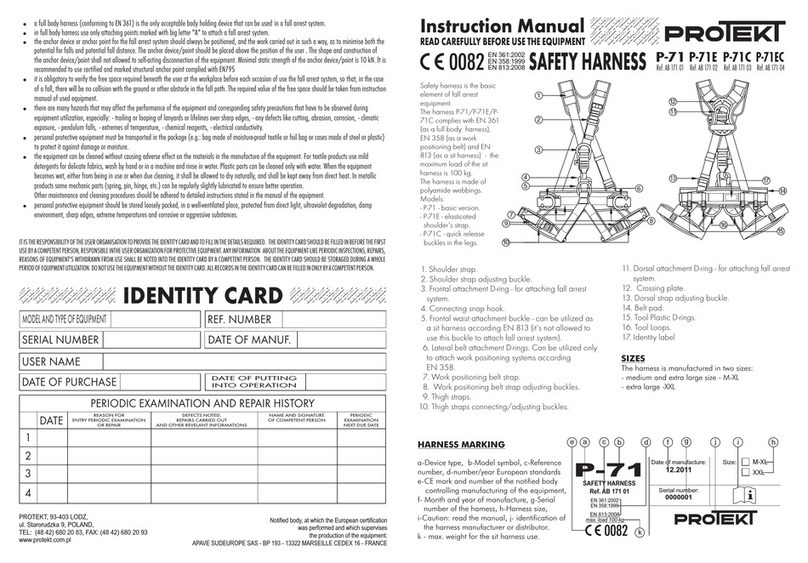

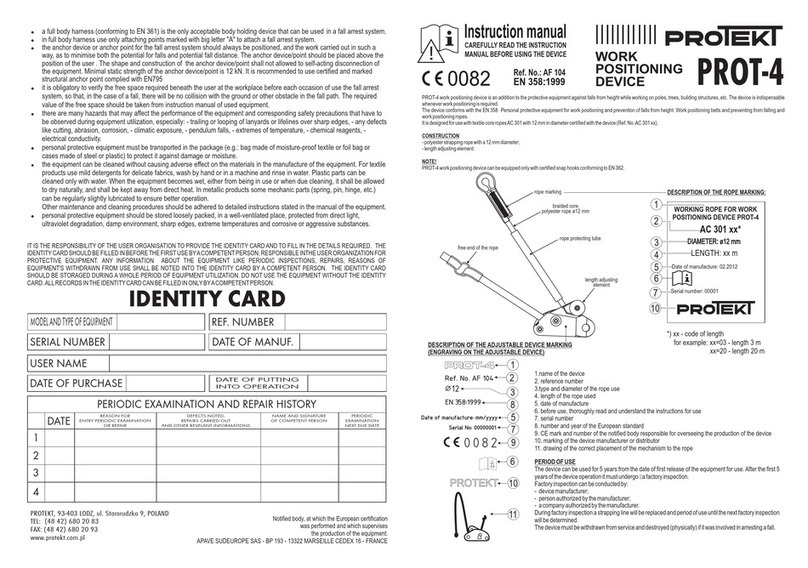

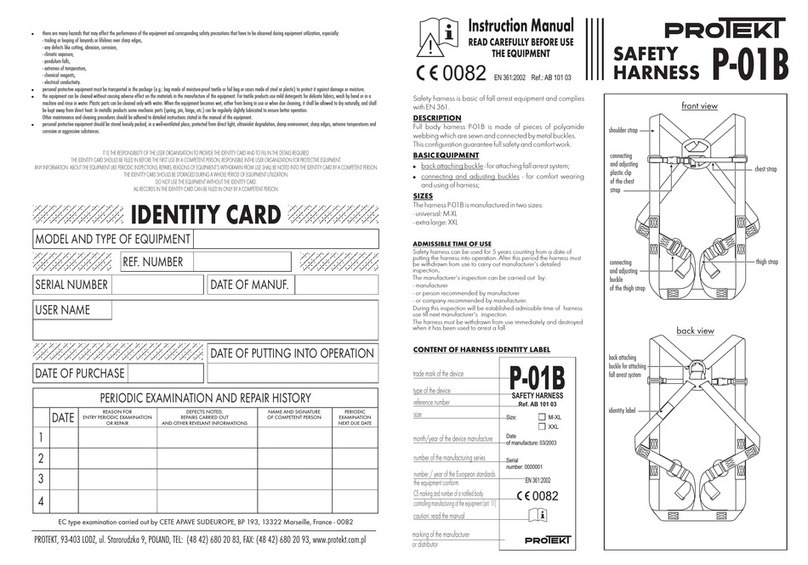

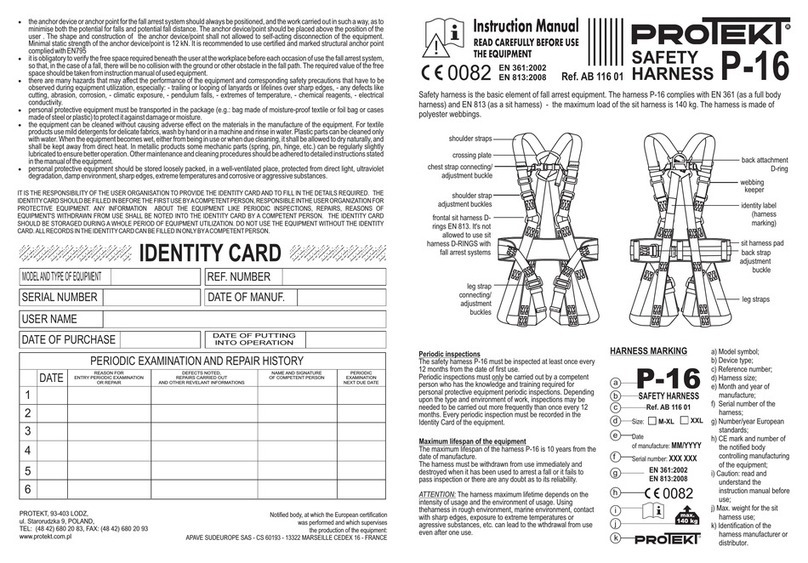

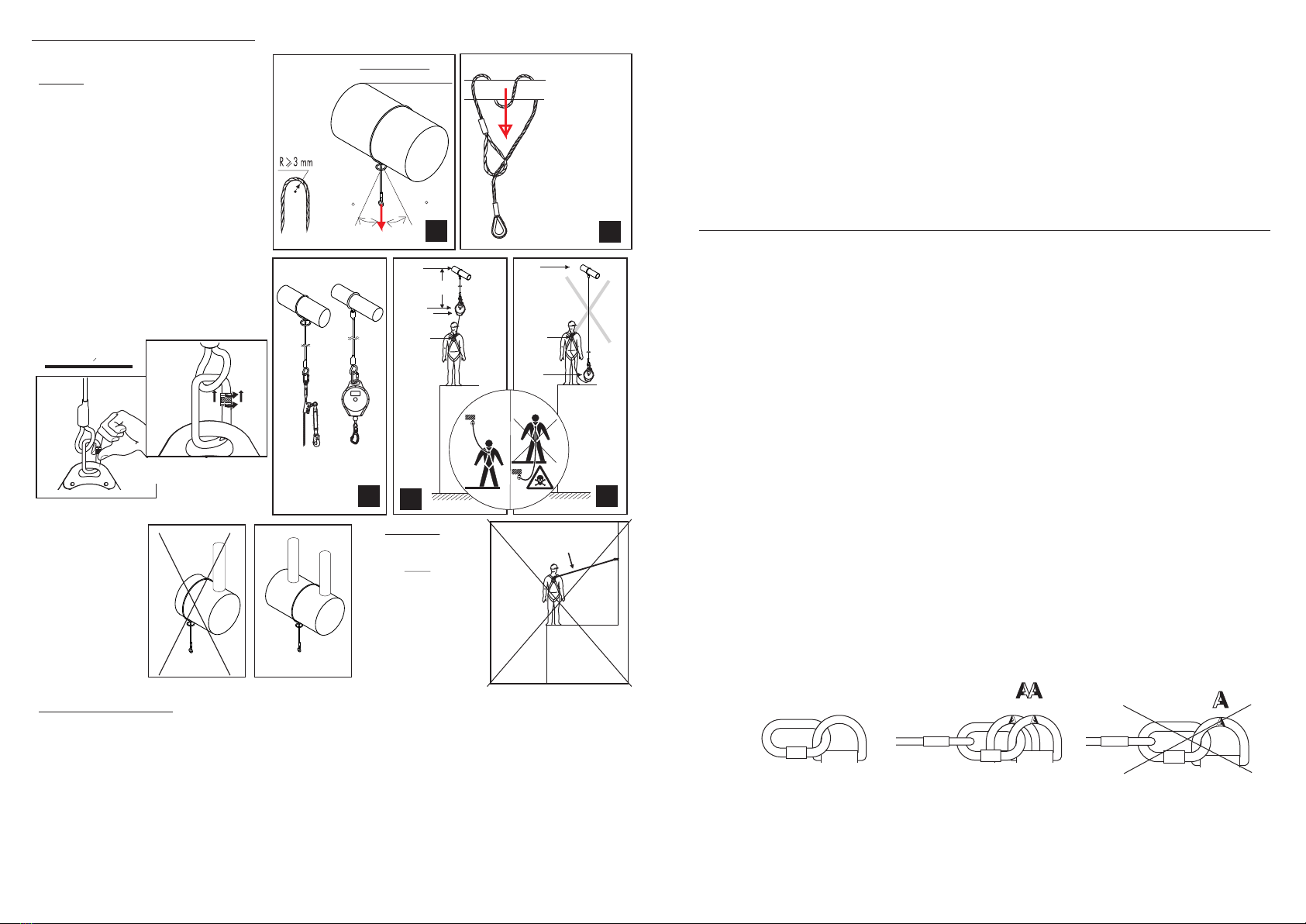

*a full body harness (conformed to EN 361) is the only acceptable body holding device that can be used in a fall arrest system.

*in full body harness use only attaching points marked with big letter "A" to attach a fall arrest system. Marking like "A/2'" or a half of "A" means the

necessity of attaching a fall arrest system to both attaching points together simultaneously. It is strictly forbidden to attach a fall arrest system to the single

attaching point marked "A/2'" or a half of "A". See drawings below:

personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT

A

FALL ARREST SYSTEM HARNESS ATTACHING POINT

AHARNESS ATTACHING HALF POINTS

FALL ARREST SYSTEM

FORBIDDEN!

Structural

Anchor

Point

min. 30 kN

Structural

Anchor Point

min. 30 kN

position

of fall arrest

device

level

of attachment

point of

a harness

Structural

Anchor Point

min. 30 kN

position

of fall arrest

device

level

of attachment

point of

a harness

INCORRECT

CORRECT

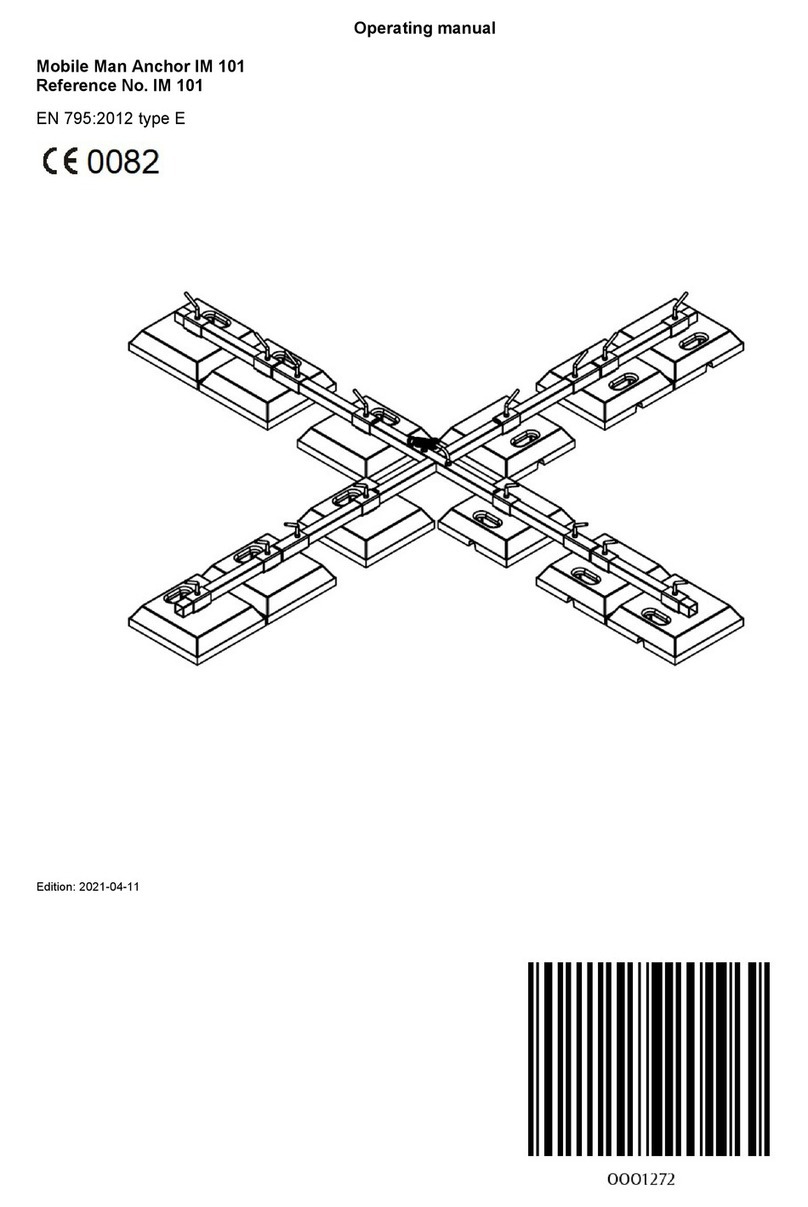

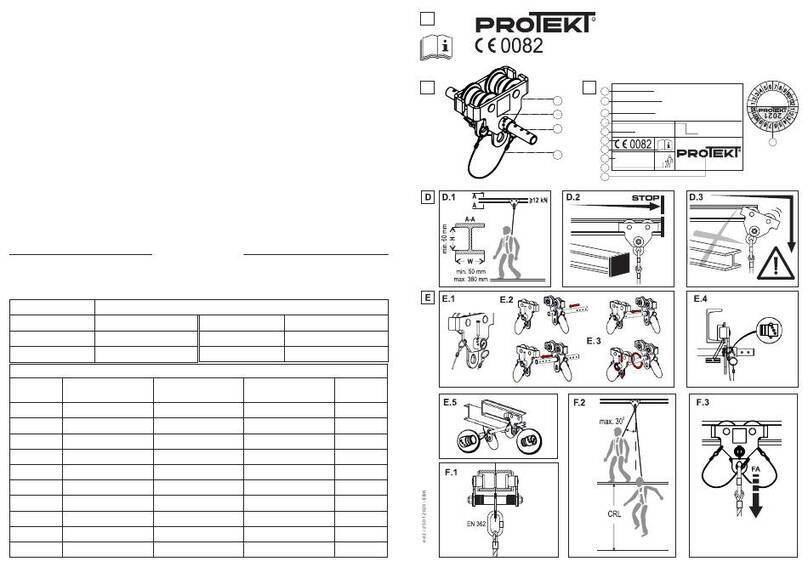

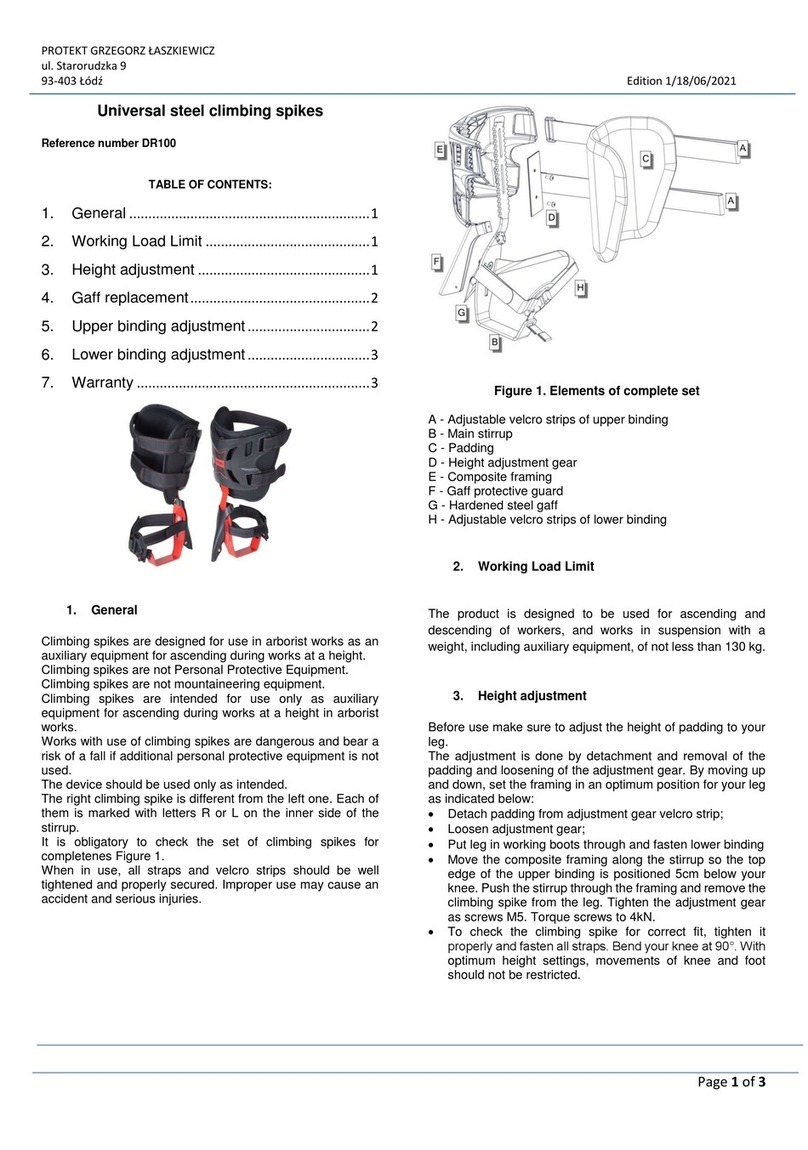

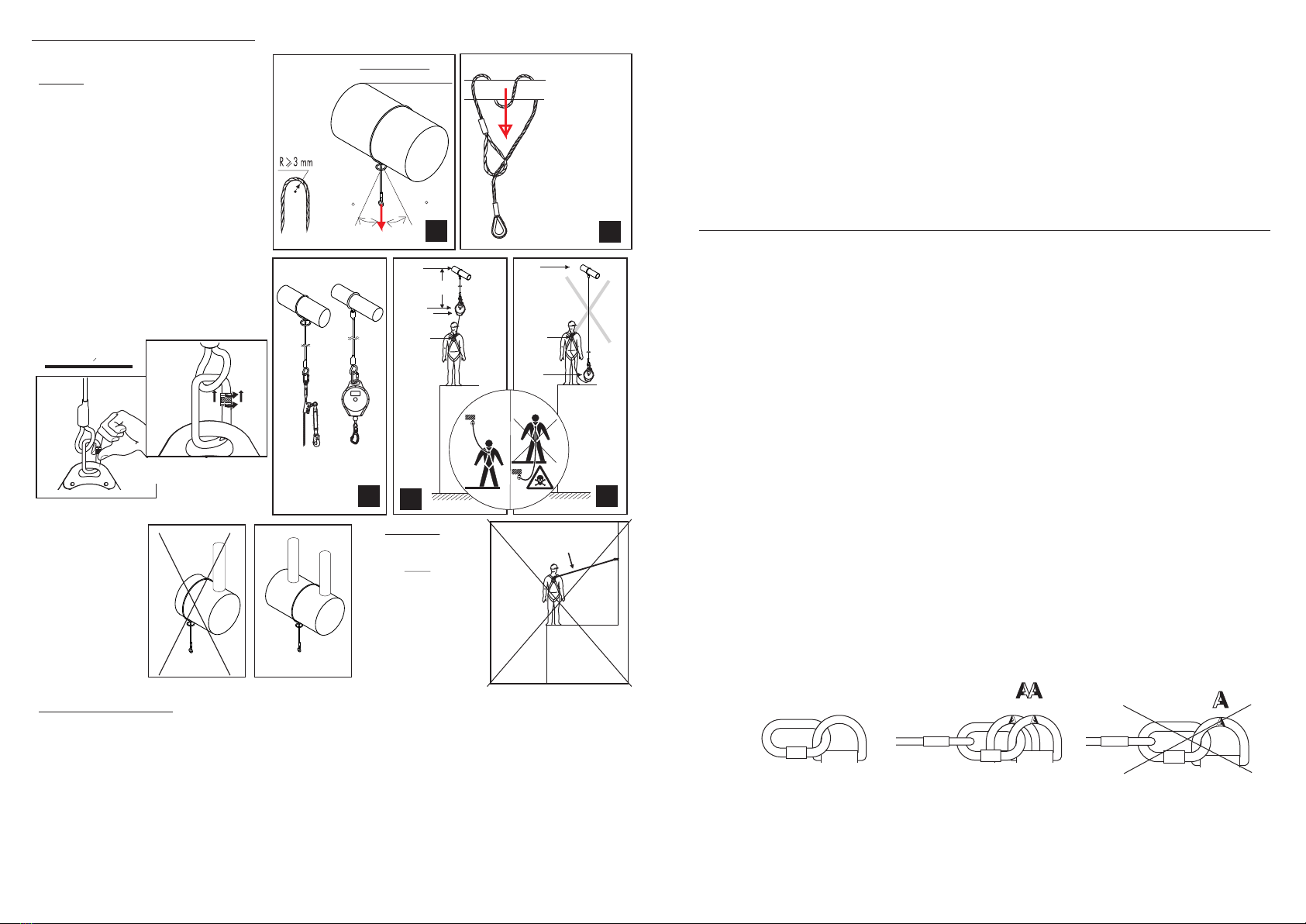

Put anchor device AT191 around a construction element (structural

anchor point).

ATTENTION: The minimal radius of the construction element must

be 3 mm without sharp edges - drawing A

.It is allowed to put a anchor device AT191 around the construction

element few times to shorten the length of a lanyard - drawing B

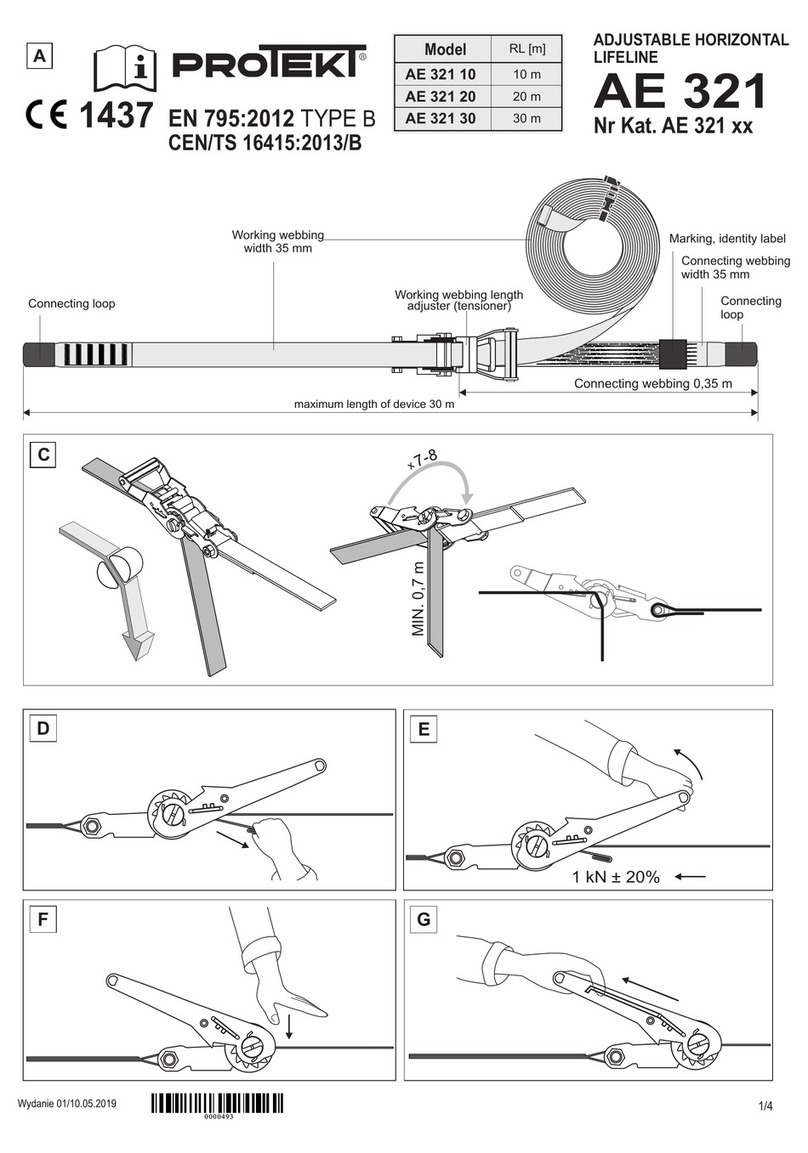

Connect a fall arrest device (e.g. retractable type fall arrester, guided

type fall arrester etc.) to the rope's snap hook - drawing C

It must be taken into consideration that during using connecting rope

an additional distance "X" appears between structural anchor

point to which the lanyard is connected and fall arrest device -

drawing D

This distance may influence functioning of fall arrest device, its

position, and fall arrest distance. All calculations concerning

safety of working place, fall arrest distance, free distance below

working level must take into account this additional distance. The

fall arrest device must be situated above the level of attachement

point of a harness to which is connected. It is strictly forbidden to

connect fall arrest device that its position is below a level of

harness attachment point - drawing E

The deflection point does not exceed 5 mm.

Check clearance beneath the user!!!

connecting

lanyard

AT191

*

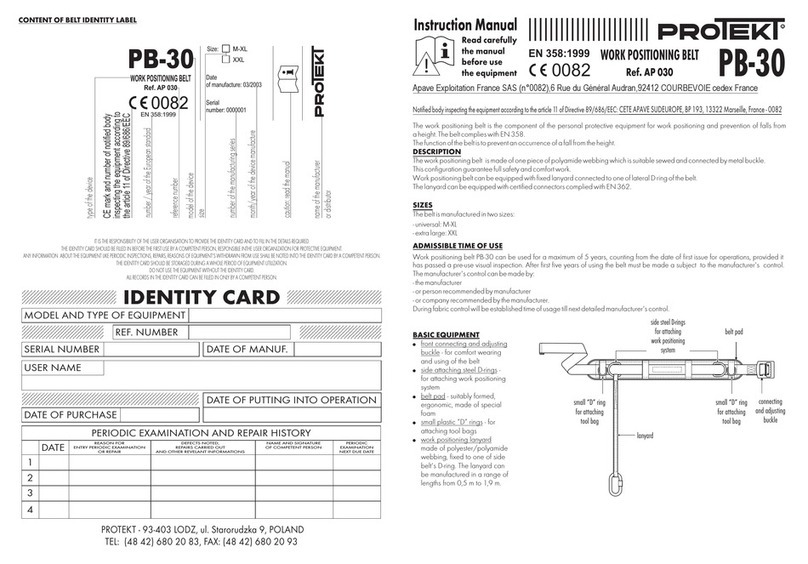

potential for falls and potential fall distance. The anchor device/point should be placed above the position of the user . The shape and construction of the

anchor device/point shall not allowed to self-acting disconnection of the equipment. Minimal static strength of the anchor device/point is 30 kN. It is

recommended to use certified and marked structural anchor point complied with EN795.

*it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so that, in the case

of a fall, there will be no collision with the ground or other obstacle in the fall path. The required value of the free space should be taken from instruction

manual of used equipment.

the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimise both the

OK !

FORBIDDEN!

BASIC PRINCIPLES OF USE

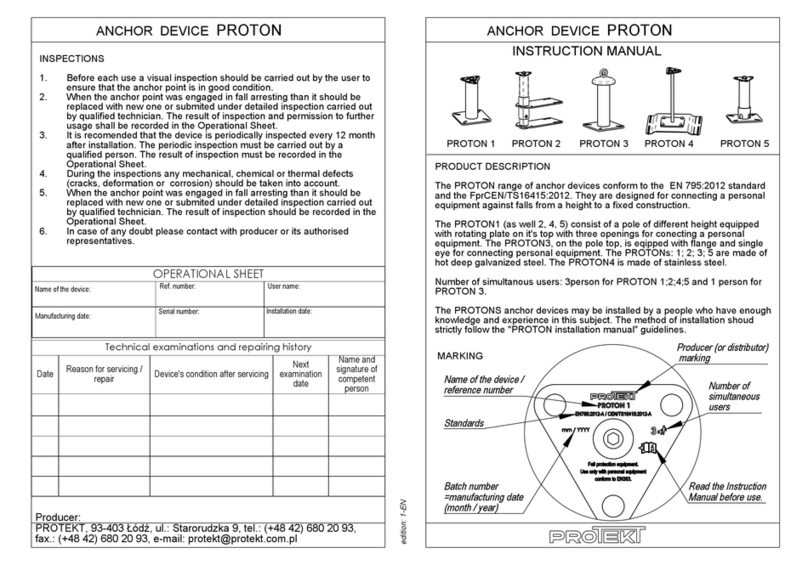

1. Before installing the anchor point, read this manual and strictly adhere to its recommendations.

2. This manual must always be available for the installer or operator of the anchor point.

3. The anchor point can be installed only by persons with appropriate knowledge and experience in this field, in particular the knowledge of the EN795

standard, the knowledge of anchor installation in accordance with the guidelines of their manufacturers and the knowledge of this manual. The installed

anchor point must be checked (approved) by a person competent in this area (e.g. an engineer or a qualified designer), who must also check the

construction the building at the attachment point in terms of its strength.

4. The constructor of the anchor point is entirely responsible for its installation. Neither the manufacturer nor the distributor is responsible for careless or

inconsistent with the recommendations assembly. Upon request, the manufacturer and/or distributor provide all necessary technical information

concerning the product, its assembly technology, inspection and the product's declaration of conformity.

5. The personal protective equipment used with the anchor point must be attached using a connector compliant with EN362, taking into account the

recommendations contained in the instructions for use of this equipment.

6. AT191 must only be used for the attachment of personal protective equipment against falls from a height, in accordance with EN795 type B , in such a

way that the created protective system complies with EN363 standards.

7. In the case of the installation in materials other than those specified in this manual (e.g. in wood) the calculations checking the compliance of the

strength of the attachment with EN795 must be commissioned to a qualified designer.

8. It is forbidden to use the anchor point with apparent defects (corrosion, cracks, deformation).

9. It is forbidden to use the anchor point, which was involved in arresting a fall.

10. It is forbidden to attach more than one person.

11. Using the anchor point for hoisting loads is forbiden.

12. Unauthorized modifications of the device are forbidden.

13. During the installation, the protective system must be planned in such a manner that the anchor point is located above the user.

14. In the protection system limiting force of fall below < 6 kN has fo be used for example retractable fall arrester or lanyard with energy absorber.

Using the anchor device AT191 in connection with fall arrest system must be compatibile with use instructions of the fall arrest systems and obligatory standards:

- EN 361 - for safety harness;

- EN 353-2, EN 355, EN 360 - for fall arrest equipment.

- EN 362 - for the connectors.

- EN 795 - for anchorages.

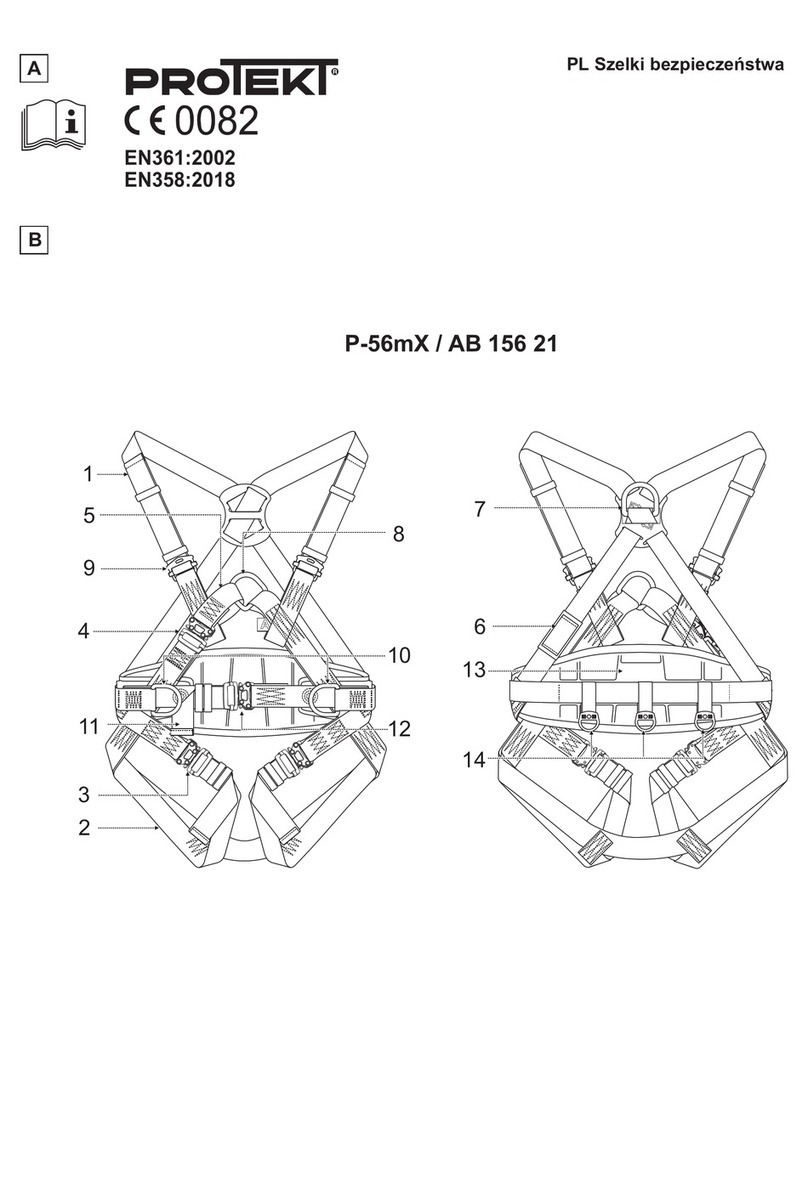

The minimum diameter

of the structural point - 50 mm

Max. loads that could be transmitted

in service from the anchor device

to the strukture - 30 kN

The directions of loading

3030

3030