2

InstructionManual

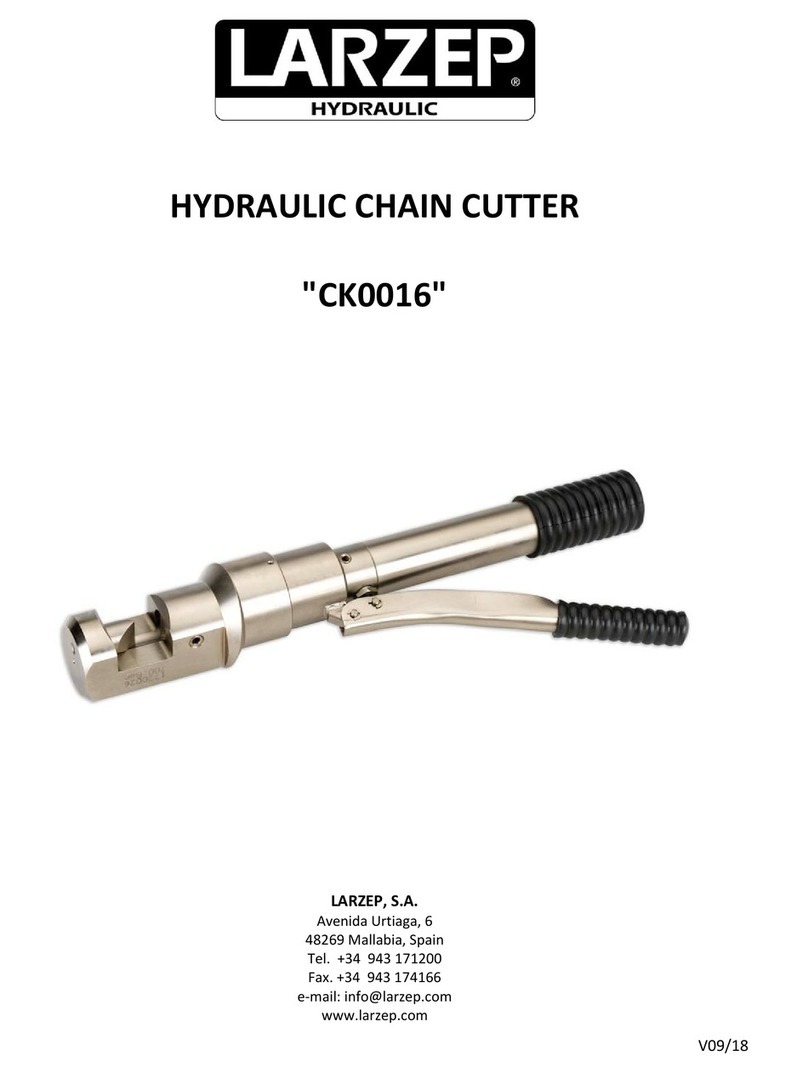

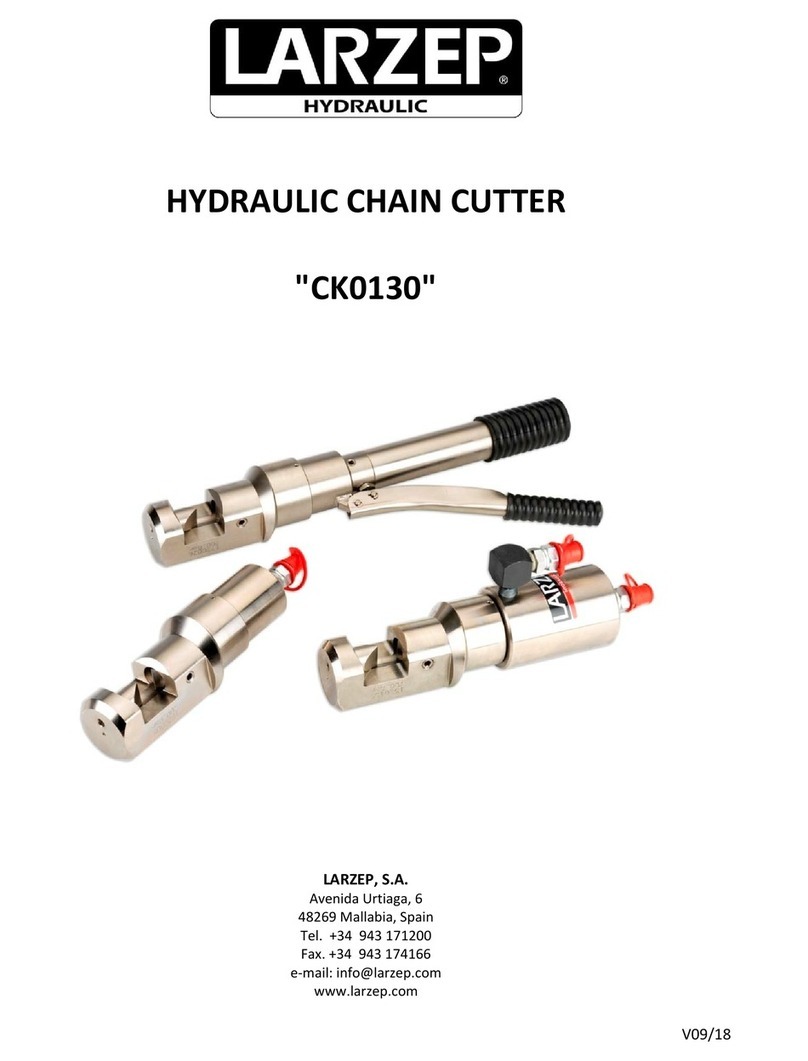

HydraulicChainCutter“CK0116”

INDEX

1. SAFETYESSENTIALREQUIREMENTS...............................................................2

2. TECHNICALFEATURES...................................................................................3

3. START‐UP......................................................................................................3

4. MAINTENANCE..............................................................................................3

5. WARRANTY...................................................................................................3

6. DECLARATIONOFCONFORMITY....................................................................4

ANNEX

GENERALDRAWINGS

1.SAFETYESSENTIALREQUIREMENTS

GENERALCONSIDERATIONS

TheLARZEPhydrauliccuttershavebeendesignedinaccordancewithourQualityStandardsandunderthecontroldescribedbytheISO9001

rules.

Thetoolisonlydesignedfortheoperationsdescribedinthismanual.Nootherusesareforeseenandthereforethemanufacturerwillnotfeel

responsibleforanydamagescausedbyawrongoperationofthetool.

ORGANIZATIVEPRINCIPLES

Theinstructionsguidemustbealwaysavailableatuser’sreach.

Hydraulicequipmentcanbeusedwithsuchlittleeffortthatitisofteneasytoforgetthemagnitudesofforceinvolved.Asacomplementtothe

instructionmanual,theusershouldbetrainedasfarasthemachineoperationandthecorrespondingsafetyandtechnicalrulesareconcerned,

suchasthoseaboutpreventionofaccidentsandprotectionofenvironment.Theoperatorsmustwearprotectiveclotheslikehelmet,glasses,

gloves,bootsandothers.

Helmet Glasses Gloves Boots

Inordertopreventanypersonalormaterialdamage,theoperatorshouldbedulytrainedintheworkingoperationandapplytherelevant

safetyactions.

Wheneverthetoolisoperated,thestepsdescribedintheparagraph“STARTUP”ofthismanualshouldbefollowed.

Any modification on the tool or replacement of components affecting the general safety should be avoided without the previous

authorisationbythemanufacturer.

Anyrepairingandmaintainingoperation,etc.shouldbedoneonlybyspecialisedstaffandwithoriginalsparepartsLARZEP.

Ifitisused,replacethehydraulichosesperiodicallyevenifatfirstsightthatdon’tshowanydamageorfault.

Effectthesuggestedmaintenanceoperationsperiodicallyasperthismanual

Afteroperation,thetoolshouldbecleanandstorefullyretractedinasafeandcleanplace.

GENERALINSTRUCTIONSFORSAFETY

Beforestartingtheoperation,makesurethattheuserwillworksteady.Operatethetoolinproperlylightpoweredareas.

Effectthemaintenanceoperationsatnopressureanddisconnected.

Donotoverpassthenominalcapacityofthemachine.Useindicatorsanddevicestobeawareoftheworkingpressure.

Allcommandsshouldbeoperatedbyhand.Donotuseanytoolsorleversforthatpurpose.

Afteroperation,cleanandstoretheminthebox.

Forsets:Cutter+pump

Makesureabouttheperfectcleaningofcouplingandaccessories.Dirtycouplingsaredifficulttoconnectandmightcausedustandother

dirtymaterialstopenetrateintothehydrauliccircuit.

Whenusingelectricpump,makesurethatthedistributorvalveisinneutralpositionwhenpluggingthepump.

Ensurethatheavyorsharpobjectsdonotfallorareplacedonthehose.Donotpressurizethehosebypumpingagainstthecoupling,before

connectingpumpandtool.

Bearing the above in mind, obviously the use of the cutter must be done as per the relevant instructions described in the

manual.Theusermustbeawareoftheinherentriskswhenhandlinghighpressurehydraulicdevices,commandproperlythe

workingoperationandinstructaccordinglythestaffstayinginthenearbyareatothetool.

Checkthat both thetooland theaccessorieshavenot experiencedanydamage during transportation,handlingorinstallation.

En

r

h

ll

h

m

n

n

f

h

h

r

li

m

n

r

h

m

xim

m

r

r

.

Limitamaximumvalueof80%ofnominalca

acit

incontinuous

Donotexposethetooltointenseheat,suchaswhenwelding