Superabrasive Owner’s Manual – Lavina® 32R-S-E 11/2014

2

1.GENERALINFORMATION................................................3

Machinecharacteristics...........................................................................3

Lavina®32R‐S‐EMaindesign....................................................................3

EnvironmentalConditions........................................................................4

ElectricalConnection...............................................................................4

VacuumConnection.................................................................................4

TechnicalData..........................................................................................4

CE‐Certification........................................................................................4

Vibrations.................................................................................................4

SONOROUSEMISSIONS............................................................................4

LabelData................................................................................................4

CustomerService.....................................................................................4

2.SAFETYISTRUCTIONS......................................................5

RecommendedUse..................................................................................5

ProhibitedUse.........................................................................................5

Preparationforwork................................................................................5

ProtectionDevices...................................................................................5

ArrestFunctions.......................................................................................5

SafeUse...................................................................................................5

ResidualRisks...........................................................................................5

BeforeYouBegin......................................................................................5

OperatingMachine..................................................................................5

AfterWorkiscompleted..........................................................................5

TheWorkArea.........................................................................................5

PERSONALPROTECTIVEEquipment(ppe)................................................5

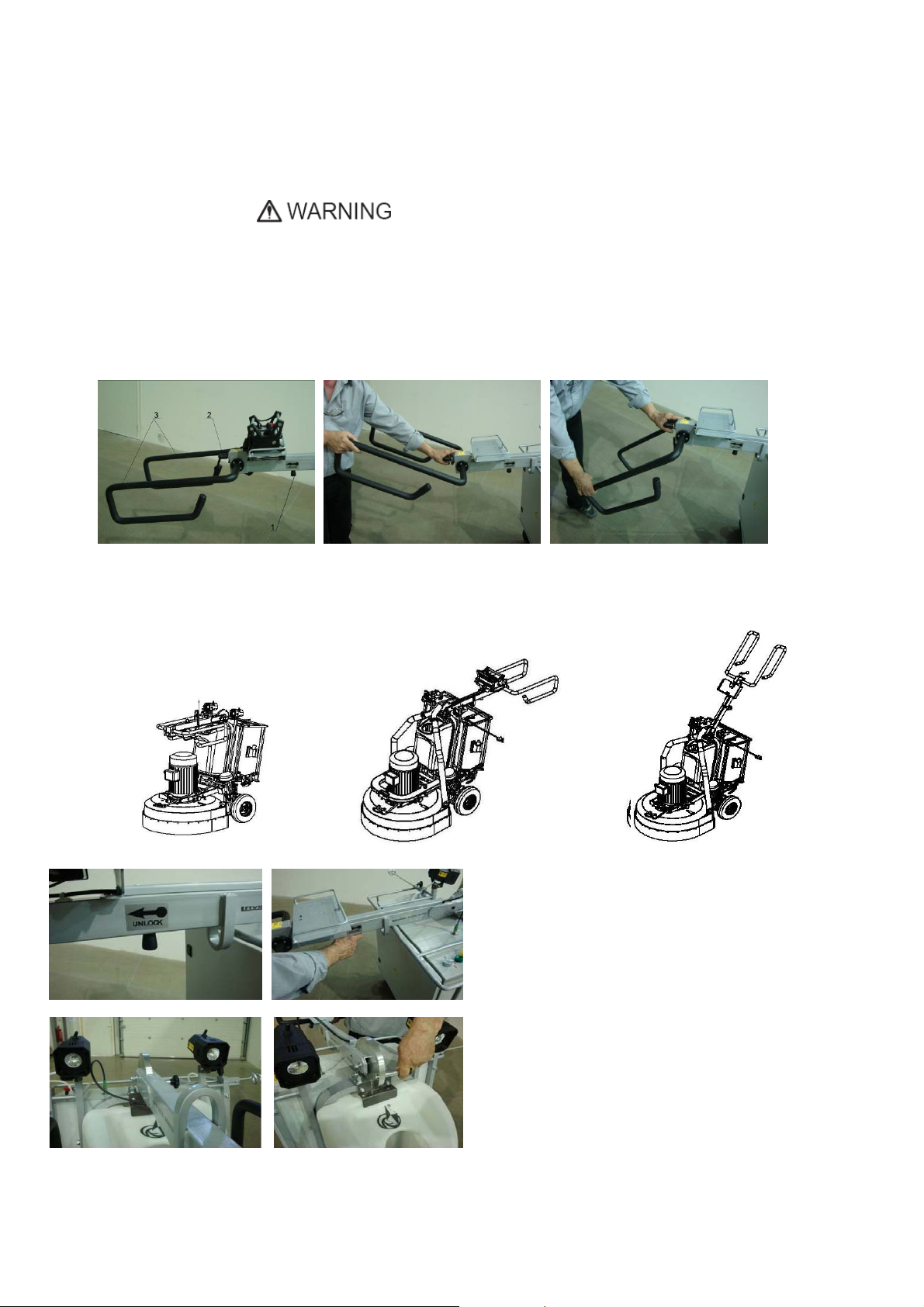

Operator..................................................................................................6

3.HANDLINGANDTRANSPORTATION................................6

Positioningthehandle.............................................................................6

Flippingthemachineup...........................................................................7

Splittingthecarriagefromthemainhead...............................................7

Lifting.......................................................................................................7

Leadingpowercable................................................................................8

Thirdwheel..............................................................................................8

RELEASINGINGTHEWHEELSOFTHECARRIAGE......................................8

Storage.....................................................................................................8

4.OPERATION...................................................................10

PreliminaryControls..............................................................................10

Controlofthewaterflow........................................................................10

AdjustingandMountingTools...............................................................10

FRAMEBLOCKING(u‐joint]....................................................................10

CONTROLPANEL....................................................................................10

OperatingtheMachine..........................................................................12

StoppingtheMachine............................................................................12

Alarm.....................................................................................................12

5.TOOLSANDACCESSORIES.............................................12

Weights..................................................................................................12

FoamPlate.............................................................................................12

SecurityplateforQuickchangepads......................................................12

6.POPULARTOOLS..........................................................13

7.EXPLODEDVIEW..........................................................14

GeneralExplodedView(fig.7.1)............................................................14

TOOLHOLDERFORMACHINESExplodedView(fig.7.2)........................14

BOTTOMCOVERASSEMBLYExplodedView(fig.7.3).............................14

PULLEYUNITExplodedView(fig.7.4)....................................................14

MOTORSUPPORTExplodedView(fig.7.5).............................................14

CENTRALSHAFTBEARINGExplodedView(fig.7.6)................................15

TopCoverExplodedView(fig.7.7).........................................................15

GUARDASSEMBLYExplodedView(fig.7.8)...........................................15

CarriageExplodedView(fig.7.9).............................................................15

STEERINGBRACKETExplodedView(fig.7.10).........................................15

ToolHolderExplodedView(fig.7.11).....................................................15

8.MAINTENANCEANDINSPECTION.................................16

Cleaning..................................................................................................16

CheckDaily.............................................................................................16

Checkafterthefirst15WorkingHours..................................................16

CheckEvery200WorkingHours............................................................16

CheckEvery400WorkingHours............................................................16

Vacuum..................................................................................................16

WaterLeaks............................................................................................16

ElectricalSystem....................................................................................16

MechanicalParts....................................................................................16

CARRIAGEWHEELS.................................................................................16

BATTERYOFTHEDRIVING......................................................................17

BaterryofthePANEL..............................................................................17

LAVINA®32R‐S‐EElectricalschemeswithYaskawaInverter380Volt.....18

9.TROUBLESHOOTING.....................................................21

IndexofProblemsandSolutions............................................................21

9.3TensioningusedplanetaryBelt........................................................22

9.4Mountingandtensioninganewplanetarybelt................................22

9.5tensioningandreplacingthebelts....................................................22

9.6replacingthePULLEYS......................................................................23

9.7replacingthewheel..........................................................................23

9.8replacingtheBATTERY......................................................................23

9.9Motorconnection.............................................................................23

FaultlistLAVINA®32R‐S‐E......................................................................24

FaultdiagnosisInverterYASKAWAV1000..............................................25

ReturnPolicyforLAVINA®32R‐S‐E..........................................................28

10.DISPOSAL...................................................................28

11.MANUFACTURER’SCONTACTS...................................28

12.SPAREPARTS..............................................................29

1.LAVINA®32R‐S‐EGeneralParts........................................................29

2.LAVINA®32R‐S‐ETOOLHOLDERFORMACHINESParts....................29

3.LAVINA®32R‐S‐EBOTTOMCOVERASSEMBLYParts.........................29

4.LAVINA®32R‐S‐EPULLEYUNITParts...............................................30

5.LAVINA®32R‐S‐EBOTTOMCOVERASSEMBLYParts.........................30

5a.LAVINA®32R‐S‐EFORALLPULLEYUNITS........................................31

6.LAVINA®32R‐S‐ECENTRALSHAFTBEARINGParts...........................31

8.LAVINA®32R‐S‐EGUARDASSEMBLYParts......................................31

9.LAVINA®32R‐S‐ECarriageParts.......................................................32

10.LAVINA®32R‐S‐ESTEERINGBRACKETParts....................................33

11.LAVINA®32R‐S‐EWaterSupplyParts.............................................33

12.LAVINA®32R‐S‐EToolHolderParts..................................................33

13.LAVINA®32R‐S‐EmotorFANParts..................................................33

14.Lavina®32R‐S‐EControlBoxParts380Volt.....................................34

LAVINA®32R‐S‐EControlBoxParts380Volt........................................34