Superabrasive UserManual OriginalLanguageLavina®25‐X 3/2015

4

WARRANTYANDRETURNS...................................................................3

1.GENERALINFORMATION...................................................................5

MANUFACTURER...................................................................................5

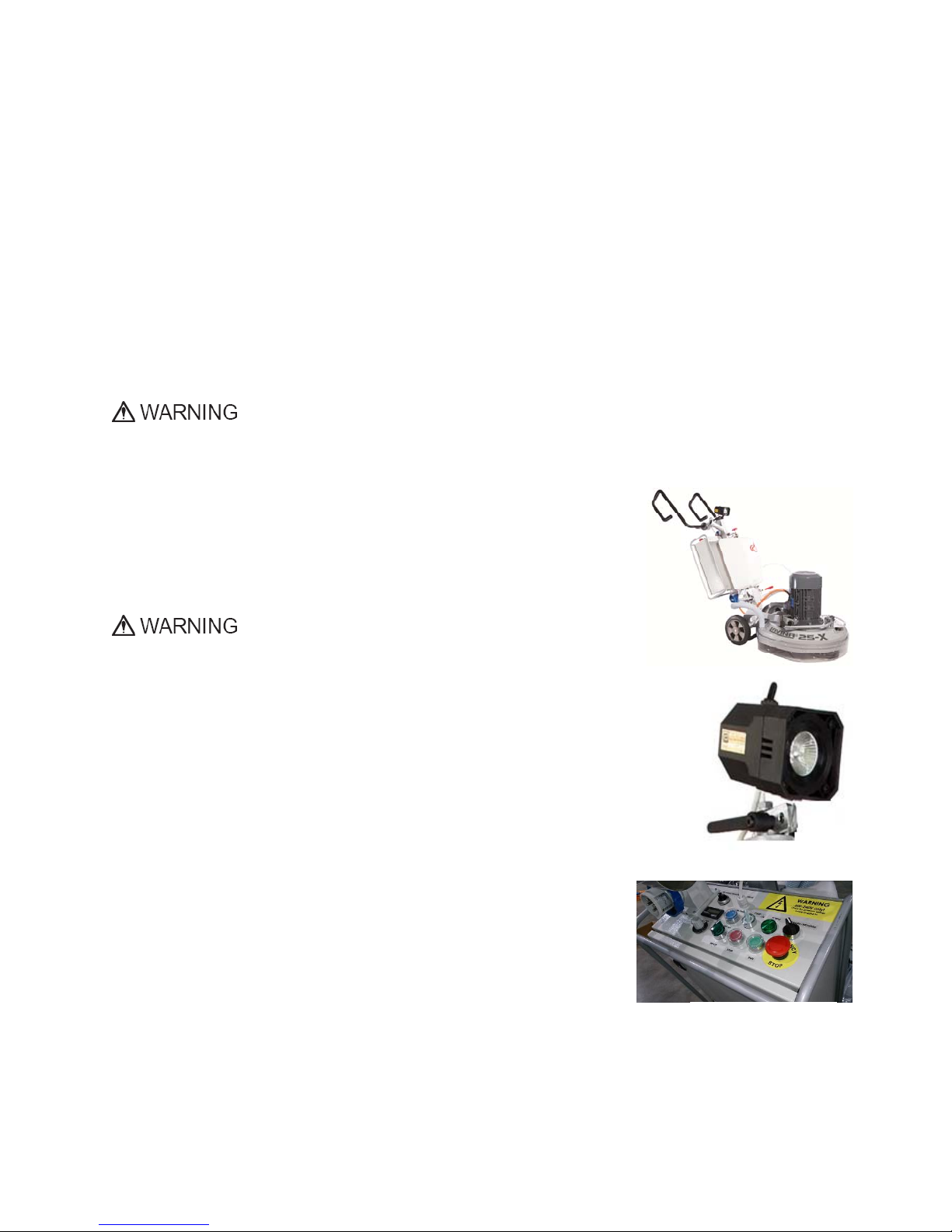

GENERALDESCRIPTION.........................................................................5

MACHINECHARACTERISTICS.................................................................5

MAINDESIGN........................................................................................5

ENVIRONMENTALCONDITIONS............................................................5

ELECTRICALCONNECTION.....................................................................5

VACUUMCONNECTION.........................................................................6

TECHNICALDATA..................................................................................6

VIBRATIONS..........................................................................................6

SONOROUSEMISSIONS........................................................................6

LABELDATA...........................................................................................6

CUSTOMERSERVICE..............................................................................6

2.SAFETYINSTRUCTIONS......................................................................6

RECOMMENDEDUSE.......................................................................6

PROHIBITEDUSE..............................................................................6

PREPARATIONFORWORK.....................................................................6

PROTECTIONDEVICES......................................................................7

ARRESTFUNCTIONS.........................................................................7

SAFEUSE........................................................................................7

RESIDUALRISKS..............................................................................7

BEFOREYOUBEGIN.........................................................................7

OPERATINGMACHINE......................................................................7

AFTERWORKISCOMPLETED.................................................................7

THEWORKAREA.......................................................................7

PERSONALPROTECTIVE...................................................................7

EQUIPMENT(PPE).................................................................................7

OPERATOR.................................................................................7

3.HANDLINGANDTRANSPORTATION..................................................8

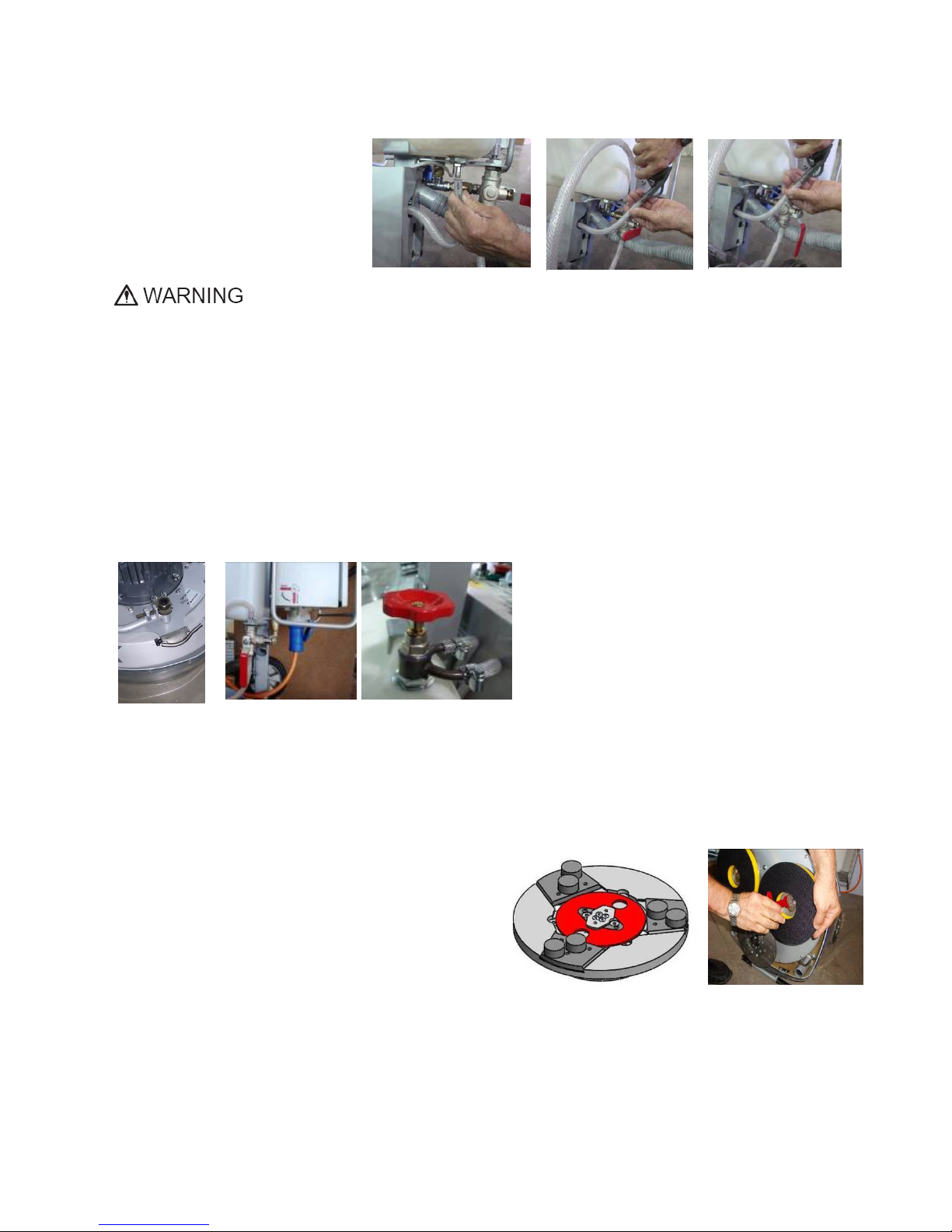

SPLITTINGTHECARRIAGEFROMTHEMAINHEAD.................................8

LIFTTHEMACHINEFROMWORKINGTOTOOLMOUNTINGPOSITION..8

LIFTING..................................................................................................8

ADJUSTINGTHEHANDLE.......................................................................8

STORAGE...............................................................................................9

4.OPERATION.......................................................................................9

PRELIMINARYCONTROLS......................................................................9

WATERFLOWCONTROLUNIT...............................................................9

ADJUSTINGANDMOUNTINGTOOLS.....................................................9

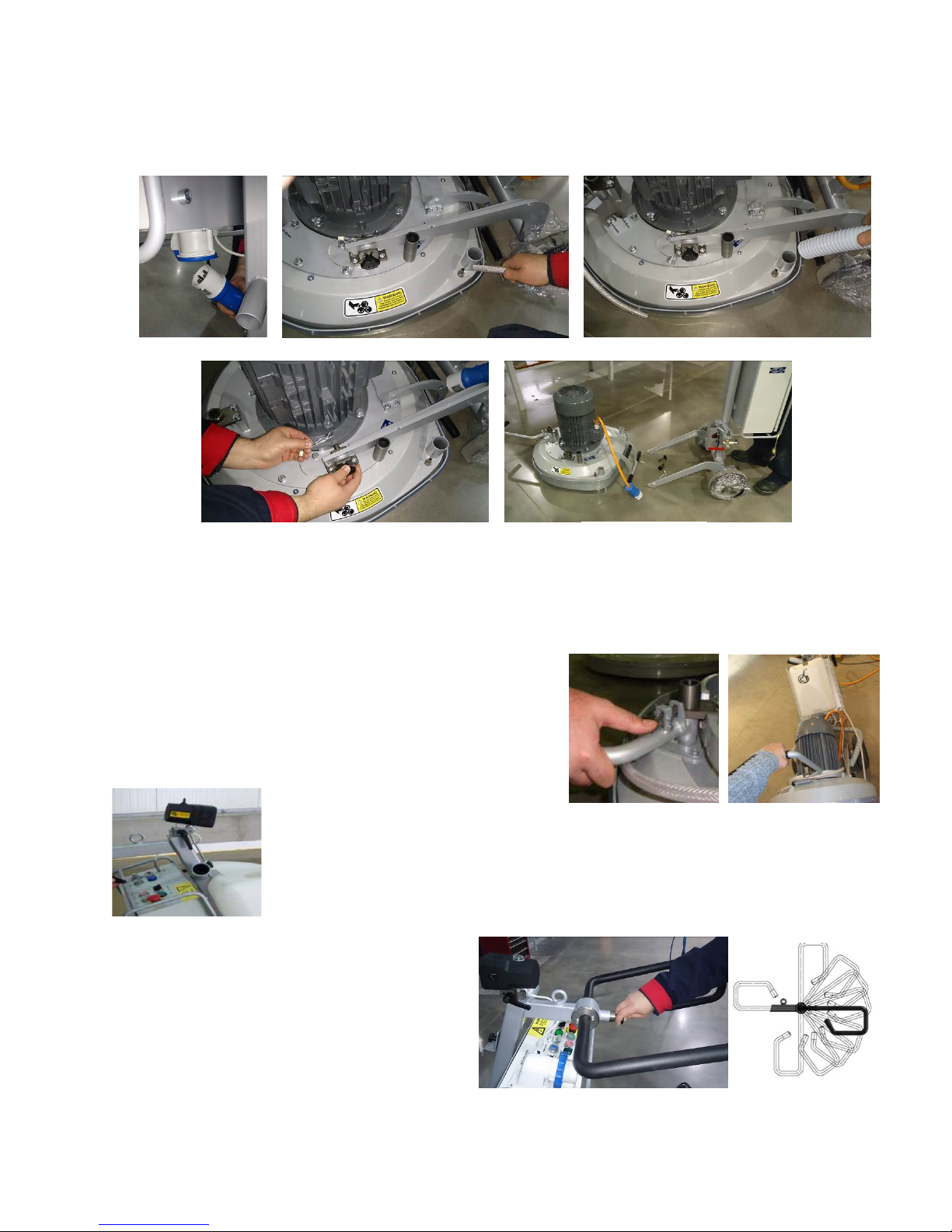

THECONTROLBOARD.........................................................................10

STARTINGTHEMACHINE.....................................................................10

OPERATINGTHEMACHINE..................................................................10

STOPPINGTHEMACHINE....................................................................10

ALARM................................................................................................10

5.TOOLSANDACCESSORIES...............................................................11

WEIGHTS.............................................................................................11

TOOLHOLDERKEY...............................................................................11

FOAMPLATE.......................................................................................11

SECURITYPLATEFORQUICKCHANGEPADS.........................................11

6.POPULARTOOLS.............................................................................12

RECOMMENDEDTOOLS......................................................................12

7.MAINTENANCEANDINSPECTION....................................................13

CLEANING............................................................................................13

CHECKDAILY.......................................................................................13

CHECKEVERY200WORKINGHOURS...................................................13

CHECKEVERY400WORKINGHOURS...................................................13

VACUUM.............................................................................................13

WATERLEAKS......................................................................................13

MECHANICALPARTS............................................................................13

ELECTRICALSYSTEM.............................................................................13

ELECTRICALSYSTEM.............................................................................13

LAVINA®25‐XELECTRICALSCHEMESWITHYASKAWAINVERTER.......14

LAVINA®25‐XELECTRICALSCHEMESYASKAWACONNECTIONMAIN

CIRCUITTERMINALS............................................................................14

8.TROUBLESHOOTING.........................................................................15

INDEXOFPROBLEMSANDSOLUTIONS................................................15

8.1REPLACINGPOWERCORDANDPLUGS..........................................15

8.2DISMOUNTINGANDMOUNTINGTOOLHOLDERTOCHANGINGV‐

RINGSANDFELT‐RINGS.......................................................................15

8.3DISASSEMBLINGANDMOUNTINGTOOLHOLDERTOCHANGE

BUFFERSANDELASTICELEMENT.........................................................15

8.4CORRECTINGSAGOFTHEUSEDPLANETARYCHAIN......................17

8.5MOUNTINGNEWPLANETARYCHAIN............................................17

8.6REPLACINGTHEPLANETARYDRIVINGCHAINWHEELAND

PLANETARYTENSIONER.......................................................................18

8.7TENSIONINGANDREPLACINGTHEBELTS......................................19

8.8REPLACINGTHEPLANETARYDRIVENCHAINWHEEL......................21

8.9REPLACINGTHEPULLEYUNITS.......................................................21

8.10REPLACINGTHEPLANETARYUNIT...............................................22

8.11MOTORCONNECTION..................................................................22

8.12FAULTDIAGNOSISINVERTERYASKAWAV1000...........................23

9.DISPOSAL.........................................................................................25

10.MANUFACTURER’SCONTACTS.......................................................25

11.SPAREPARTS.................................................................................26

ASSEMBLYANDPARTSSPECIFICATIONS..............................................26

1.LAVINA®25‐XGENERALPARTS........................................................26

2.LAVINA®25‐XTOPCOVER1PARTS.................................................26

3.LAVINA®25‐XTOPCOVERPARTS2..................................................27

4.LAVINA®25‐XGUARDPARTS...........................................................27

5.LAVINA®25‐XBOTTOMCOVER1PARTS.........................................27

6.LAVINA®25‐XPLANETARYDRIVEPARTS.........................................28

6.1.LAVINA®25‐XPULLEYUNITASSEMBLY......................................29

7.LAVINA®25‐XBOTTOMCOVER2PARTS.........................................29

8.LAVINA®25‐XWATERTANKPARTS.................................................30

9.LAVINA®25‐XTOOLHOLDERPARTS................................................30

10.LAVINA®25‐XCARRIAGEPARTS....................................................31

11.LAVINA®25‐XCONTROLBOXPARTS200‐240VOLT.......................32

LAVINA®25‐XCONTROLBOXPARTS200‐240VOLT...........................32