LAWRENCE FACTOR HF-961-111 Guide

O f O p e r a t i o n , S e r v i c e a n d P a r t s

M A N U A L

Purification Appliance Model

HF-961-111

High Purity At High Pressure

The information contained herein is based upon our testing and experience. It is believed to

be accurate. Since operating conditions may vary and since we do not control such

conditions, Lawrence Factor, Inc. DISCLAIMS ANY WARRANTY, EXPRESSED OR

IMPLIED, with regard to the use of our products.

Due to the evolving nature of our products and our continued effort to improve those

products, the information contained in this publication may not be identical to the product.

Copyright © 2006, Lawrence Factor, Inc.

4740 NW 157 Street,

Miami Lakes, Florida 33014

305 430-0550

High Purity At High Pressure

COPYRIGHTS & TRADEMARKS

L-Factor Trademarks: Aero Lube, CO-Cop, Lab on Locale, L.F.W., L-Factor, Monoxycon, New Parts, Oxy Lube, Seco Lube, Vaporshell, and X-tractor are

TRADEMARKS of Lawrence Factor, Incorporated. X-pendable, X-zam, and Lawrence Factor are REGISTERED TRADEMARKS of Lawrence Factor, Inc.

Other Trademarks: A2LA is a registered trademark of American Association for Laboratory Accreditation. Aero Dri is a registered trademark of Kiko,

Incorporated. Air Dry Corporation of America is a registered trademark of Air Dry, Corporation. American Bristol is a registered trademark of American

Bristol, Industries. ANDI is a registered trademark of American Nitrox Divers, Incorporated. Bauer Compressors is a registered trademark of Bauer

Compressors, Incorporated & Bauer Kompressoren, GMBH. Bristol Pneumatics is a registered trademark of Bristol Pneumatics, Limited. C.G.A. is a

registered trademark of Compressed Gas Association, Incorporated. C.S.A. is a registered trademark of Canadian Standards Association. Coltri-Sub is a

registered trademark of Aerotecnica Coltri, Incorporated. Deltech and Del-Monox is a registered trademark of Deltech Engeneering, Incorporated. Eagle

Compressors is a registered trademark of Eagle Compressors, Incorporated. Fluid Concepts is a registered trademark of Fluid Concepts, Incorporated.

Hamworthy is a registered trademark of Hamworthy USA, Incorporated and Hamworthy Engeneering, Limited. Ingersoll-Rand is a registered trademark

of Ingersoll-Rand, Company. Innerspace Research is a registered trademark of Innerspace Research, Incorporated. Jordair is a registered trademark of

Jordair Compressors, Incorporated. Mako Compressors is a registered trademark of CompAir Mako, Incorporated. Max-Air is a registered trademark of

Max-Air Compressors, Incorporated. Midland Diving Equipment is a registered trademark of Midland Diving Equipment, Limited. N.A.V.S.E.A. is a

registered trademark of Naval Sea Systems Command. N.F.P.A. is a registered trademark of National Fire Protection Association. Nautica is a registered

trademark of Nautica, Incorporated. O.S.H.A. is a registered trademark of Occupational Safety and Health Administration. Poseidon Compressors is a

registered trademark of Poseidon Kompressoren GEMSBH & Bauer Compressors Inc. Pressure System is a registered trademark of Pressure System,

Incorporated. Robbins Aviation is a registered trademark of Robbins Aviation, Incorporated.

Aftermarket Use: X-pendable filter cartridges, New Parts compressor parts, and many other items depicted in the pages are intended and sold for

aftermarket use only. Part numbers, graphics, photos, trade names, and corresponding printed matter are not intended to imply that any items in

this Catalog or Website are original brand products. Although the quality of most of the items listed herein equals or exceeds the performance of

the original brand, none of these items are manufactured or associated with the original manufacturer. L-Factor in no way represents itself or it's

products to be related to the OEM or their brands.

Lawrence Factor, Incorporated - 4740 NW 157 Street, Miami Lakes, Florida 33014 - © All Rights Reserved

TABLE OF CONTENTS i

Table of contents

Table Of Contents. . . . . . . . . . . . . . . . . . . . . . . . i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Identification Of Components . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cartridge Installation . . . . . . . . . . . . . . . . . . . . . . 7

Cartridge Installation . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supplements . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model Number

Design Gas (Gases)

*Maximum Process Gas

Maximum Operating Pressure

Minimum Operating Pressure

Repressure Cycle Life

Safety Factor

Maximum Operating Temperature

Minimum Operating Temperature

Maximum Ambient Temperature

Minimum Ambient Temperature

Power Supply

Ground Strap Requirement

Dimensions

Inlet Port Size

Discharge Port Size

Auxiliary Port Size

Non Adjustable Restricted Flow

HF-961-111

Compressed Air or Inert Gas

*18,000 Cubic Feet

5,000 PSI

2,000 PSI

15,000 Cycles for Cartridge Holders

4:1 (ASME)

0

100 F

0

-40 F

0

105 F

0

-40 F

Not Applicable

Required (Not Supplied)

11” W x 38” H x 5” D

1/4”

1/4” FNPT

1/4” FNPT

9 SCFM At 3200psi

“HF SERIES” PURIFICATION APPLIANCE 1

Specifications

* Dependant on actual operating conditions.

“HF SERIES” PURIFICATION APPLIANCE

2

Safety Warnings

Safety

Isolate appliance from gas stream and depressurize prior to any service action. Never direct compressed gases at

bodily openings, eyes, or skin. Empty volatile gases from appliance into "drain gas” accumulator. Use appropriate

monitoring devices when dealing with critical or life support gas. Never exceed maximum operating conditions set

forth herein and/or on appliance nameplate. DO NOT use this appliance with Oxygen or Oxygen rich gas mixtures.

DO NOT connect this appliance to any system common with compressed oxygen. Disconnect all power supplies prior

to any service action. Some components used on this appliance may have a limited cycle lifespan and must be

replaced after that span has lapsed. Carefully read supplement section.

WARNING: When performing installation, adjustments, or any kind of service work: ensure that ALL pressure has first

been released and that ONLY trained personnel are carrying out tasks. NEVER remove retaining or adjusting screws

while device is under pressure. Safety valve should be returned to factory for service.

*Use only genuine Lawrence Factor replacement parts in order to guard the validity of your warranty and reliability of this appliance.

“HF SERIES” PURIFICATION APPLIANCE 3

Introduction

Introduction

This L-Factor appliance is a “special application” compressed gas purifying system designed to operate at high

pressures. It is intended to treat once purified gas a second time (second stage purification) in order to achieve

ultrahigh levels of purity. This is a “once through” type appliance utilizing Disposable Cartridges. The appliance, or

hardware, operates in concert with the cartridges, or software, which are the core of the system.

With the compressed gas entering the device, it is preconditioned by an optional Mechanical Filter and then flows

evenly through a series of Cartridge Holders. These towers contain the Disposable Cartridges which can be

configured according to customer needs and applications. It is of paramount iportance that the user not vary from the

cartridge models specified on the appliance. Always change all cartridges at the same time, as a set.

On some models, a cartridge change indicating device (Eyeball Indicator) is fixed at the inlet to the tower chain in order

to tap off a sample of the gas for constant evaluation. The standard device will indicate RH of the gas by coloremetric

change as viewed through a window placed at the topside of the “Eyeball”. Replacement elements are available for a

range of RH as well as other kinds and levels of substances.

In the case of compressed air, a minimum level of grade “E” (according to the CGA) is expected to enter the appliance.

The gas now follows a path through a final Micronic Filter towards discharge at the Priority Valve and into the outlet

piping.

The standard Appliance is supported on an angle plate chassis that facilitates fixing to a permanent vertical

foundation or hanging from another equipment. There is a Pressure Gauge at the discharge manifold in addition to a

system Drainage Valve. Some models are supported by an optional freestanding chassis which also supports

electronic monitoring units.

Special attention has been paid to all materials and treatments in order to guard the ability of this equipment to achieve

the high gas purities required of it. Carefully follow the instructions set forth in this manual and use added precautions

to avoid internal contamination.

It is of paramount importance that the user does not exceed the operating limitations set forth for this appliance. Do

Not exceed pressure, flow rate, or temperature ratings.

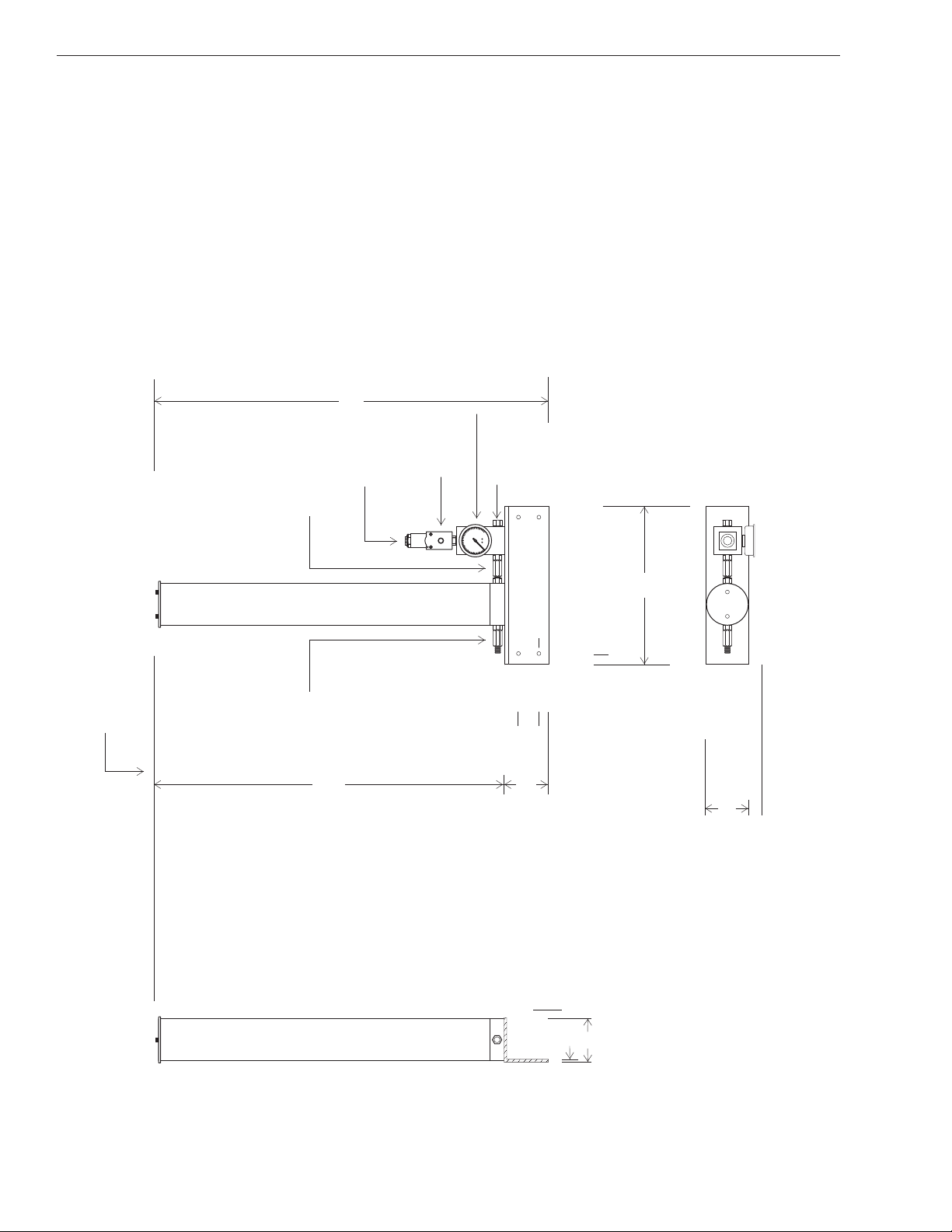

Identification of Components

Refer to this illustration in order to identify components as they are discussed throughout the remainder of this

manual. Be aware that some items may not appear in the exact form as they exist on the actual appliance.

“HF SERIES” PURIFICATION APPLIANCE

4

Identification

½” Holes

Allow 28” Overhead Clearance For Cartridge Change

34”

Check Valve Check Valve

Priority Valve

4” 2”

1”

1”

Side View

4”

1/4”

11”

4”

1”

1”

Outlet

(1/4” NPT)

Vent

Micronic Filter (Internal)

Top View

38”

“HF SERIES” PURIFICATION APPLIANCE 5

Instalation

Installation

It is assumed that the person installing this equipment is experienced in this field and fully acquainted with the

standard engineering practices.

Carefully unpack unit while ensuring to protect any sensitive devises such as pressure gauges and instruments.

DO NOT open any valves until unit is fully installed. This appliance has been carefully cleaned and protected against

contamination by atmospheric substances.

Refer to "IDENTIFICATION" page of this manual for location of components.

Appliance should be permanently affixed to a solid foundation by means of the anchoring holes located at the back of

the angle plate or (in the case of freestanding models) on the feet of the main chassis. Consider all piping joints when

orienting unit. DO NOT expose to excessive vibration.

Make up piping connections using joint compound which is compatible with the compressed gas application. If using

Teflon tape, do not allow to overlap edges of fittings since pieces may break loose under operation and cause

blockages.

Ÿ INLET CONNECTION should be made with a flexible hose.

Ÿ DISCHARGE CONNECTION should be made with a flexible hose. Note that the discharge is located at the

“back pressure valve" and there are two (2) ports for your use, one may be plugged if not required.

ŸRELIEF VALVE (if supplied) vents to atmosphere. An optional valve is available with NPT vent connection to

facilitate controlled discharge. Never tamper with relief valve settings.

ŸSYSTEM VENT discharges to atmosphere. An optional valve is available with NPT connection to facilitate

controlled discharge.

ŸA GROUNDING STRAP (not provided) must be attached to appliance.

ŸADEQUATE CLEARANCES must be allowed for servicing and cartridge changes.

ŸPROVIDE MEANS OF ISOLATION of this appliance from gas stream during service and cartridge changes.

ŸCONTAMINANT DETECTION (Optional) and alarm should be installed at discharge of appliance when in life

support air/gas service.

ŸOVER TEMPERATURE PROBE (Optional) and alarm with system shutdown devise should be installed at

discharge of compressor system as well as at the discharge of this appliance.

DO NOT install in location where ambient temperatures could exceed 110F degrees. DO NOT expose to electrical

charges or sparks. DO NOT install in system where gas flow rates could exceed the rating of this appliance. The

cartridge set must be installed prior to placing appliance into service. See section on “Installing Cartridges”.

“HF SERIES” PURIFICATION APPLIANCE

6

Start Up / Operation

Start Up

The following procedure must be followed on initial start-up (AFTER CARTRIDGES HAVE BEEN INSTALLED) and

on each occasion where the appliance has been shutdown, serviced, or had a cartridge change.

NOTE that some appliances will come supplied with storage elements installed and slightly pressurized.

ŸVENT pressure from appliance using "System Vent". Be careful to drain the appliance slowly.

ŸREMOVE CARTRIDGE elements from holders according to "Cartridge Change" instructions and install new

cartridge elements. (This is done ONLY on initial start-up and on occasions where elements are due for change)

ŸCLOSE "System Vent Valve".

ŸPRESSURIZE appliance (SLOWLY) by opening the "Inlet Isolation Valve" (Optional). Bring up to full operating

pressure in 500 PSI steps while verifying there are no leaks in system.

ŸFLUSH contaminants from main appliance and piping by opening the "Outlet Isolation Valve" (Optional) and

permitting a small flow of air to discharge downstream or to atmosphere.

ŸTHE APPLIANCE MAY NOW BE PLACED ON LINE by fully opening the "Isolation Valves".

Operation

PRECAUTIONS: Always employ safe practices in handling of volatile or respiratory gases. Wear protective gear

when installing, operating, or servicing compressed gas apparatus. Never smoke, cause sparks or fire, or switch

electrical equipment while in the presence of volatile gases. MSDS are available for materials contained in disposable

cartridges. Use approved methods of disposal for cartridges. Never exceed ratings of this appliance.

INSTALLATION: Appliance must be properly installed prior to operation. See section titled "Installation".

CARTRIDGE INSTALLATION AND CHANGES: Cartridges must be properly installed prior to operation. See section

titled "Cartridge Installation".

SERVICE AND MAINTENANCE: See section titled "Maintenance Schedule" and instructions for each individual

component at the "Supplements" section of this manual.

Once the appliance is running it will manage itself. The operator need only perform proper maintenance, drain

condensate from mechanical filter when needed, and cartridge changes when due. The "Eyeball Indicator" will assist

the operator in determining cartridge change. See "Supplements" section of this manual.

DRAINING CONDENSATE FLUID must be done on a periodic basis. Since each system is operating under various

conditions the intervals between drainings should be established after operating experience.

“HF SERIES” PURIFICATION APPLIANCE 7

Service Of Cartridges

Installation of Cartridges

PRECAUTIONS: Always depressurize and remove electrical source from this appliance prior to performing any

service. Do Not direct compressed gases at bodily openings, eyes, or skin. Do Not attempt to regenerate disposable

cartridges. Do Not rotate cartridges - always replace all cartridges as a set, otherwise contaminants could be

reintroduced to gas stream.

CARTRIDGE SERVICE INTERVALS: This appliance can only process the amount of gas rated on the nameplate of

the appliance as well as on the front page of this manual. Cartridges must be changed at their maximum calculated life

or every six months, whichever comes first. Many variables will contribute to the capability of this equipment. It is our

recommendation that a reliable monitor be placed at the discharge point in order to gauge the humidity level of the gas

in determining the appropriate change of cartridges. Otherwise, approximated cartridge change can be calculated

with the following formula.

This formula is based on average operating conditions for appliance. Low pressures or high temperatures will reduce useful cartridge life.

Gas Process Rating of Appliance in SCF

SCFH Gas Flow =Life expectancy of cartridge set

in operating hours

TOOLS REQUIRED: Spanner wrench (available from

manufacturer) or 5/8" closed end wrench, non-hydrocarbon

grease with applicator, graphite paste, leak detector pliers

and a flashlight.

PROCEDURE: Refer to "IDENTIFICATION" page of this

manual for location of components. Turn system "OFF" and

isolate appliance from gas stream by means of isolation

valves (optional). Vent compressed air from system by means

of system pressure release valve. Monitor gauges to be

certain that appliance is empty.

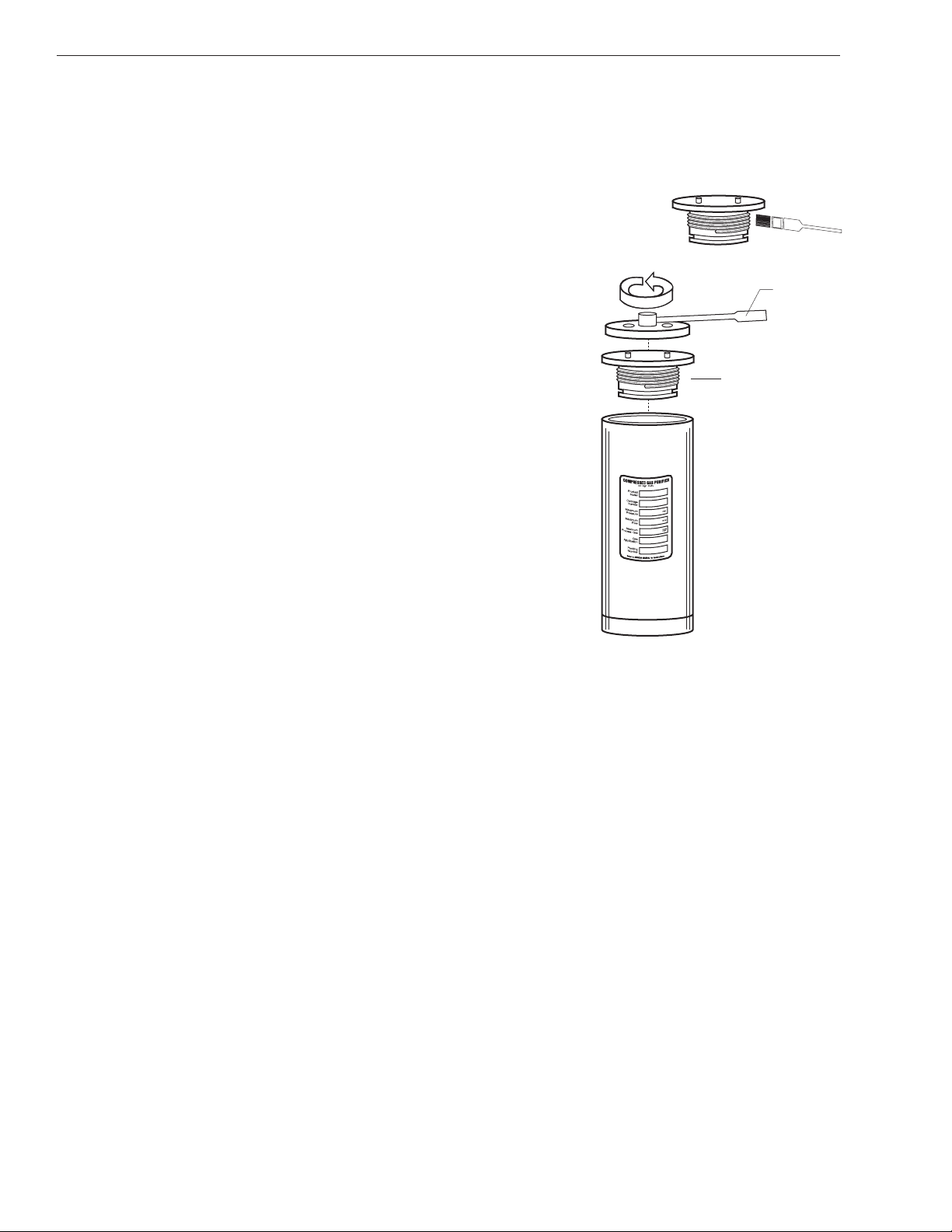

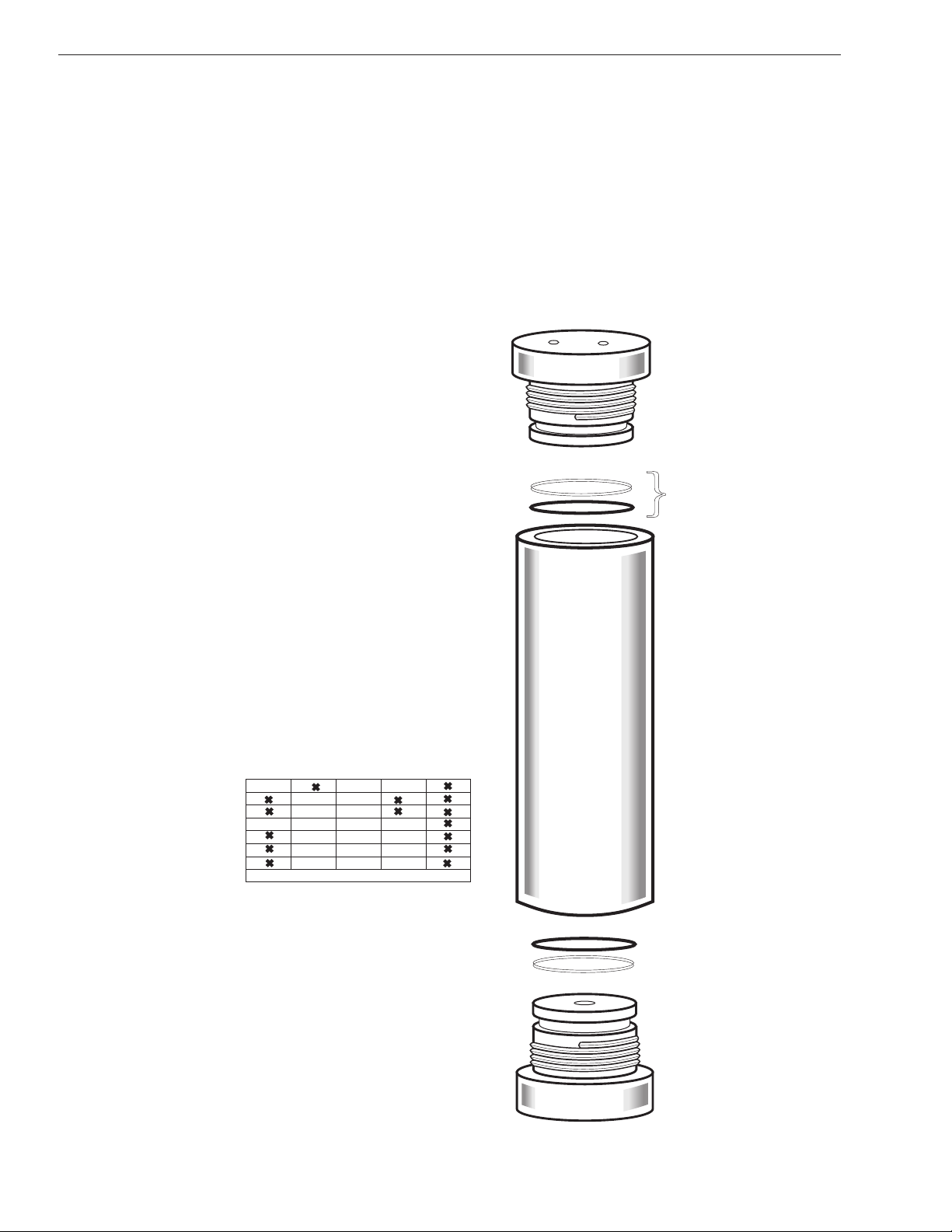

Remove cylinder head(s) from cartridge holder(s) as

illustrated. You should be able to turn the cylinder head with

moderate pressure. If force is required, STOP and recheck

appliance pressure to verify that it is empty.

Lift spent cartridge from cylinder using the lifting bail provided

at top of cartridge.

Using flashlight CAREFULLY inspect interior of cylinder for

extraneous matter and any wear exhibited on the cylinder

walls. Any deterioration may be cause for replacement.

Remove cartridges from packaging, one at a time, holding

them with the outer wrapper used as a "glove" in order to

prevent contamination by handling. Remove lower protective

seal from mating end of cartridge. Suspending cartridge by

lifting bail, lower new cartridge into place. NEVER drop

cartridge into cylinder. Apply slight pressure to seat cartridge

onto mating stem/port of cylinder.

SPENT

NEW

Installation of Cartidges

PROCEDURE (continued) Using applicator, lubricate cylinder head O-

Ring(s) with non-hydrocarbon grease. Also, apply a light film of graphite

paste to the threads using care not to contaminate interior of cylinder

(non-hydrocarbon grease may be used in place of the graphite paste).

Note that the cylinder foot should be serviced periodically in this same

manner. Refer to the maintenance schedule for recommendations

Reassemble in reverse order using the spanner wrench. If binding is

encountered STOP and check for obstructions, cartridge position, and

thread clearance. DO NOT over tighten cylinder ends. Tighten until dust

cover or lip touches cylinder and then back out slightly.

Open the inlet isolation valve to permit gas flow into appliance.

Repressurize in 500psi steps while checking for leakage until working

pressure is reached. Verify appliance pressure by means of the gauges.

Note that the back pressure valve will limit gas flow from leaving

appliance until pressure range of 1800-2200psi is reached.

Purge contaminated air from system by means of the system pressure

release valve.

Open discharge isolation valve to place appliance back on line.

“HF SERIES” PURIFICATION APPLIANCE

8

Service Of Cartridges

SPANNER

WRENCH

HEAD

“HF SERIES” PURIFICATION APPLIANCE 9

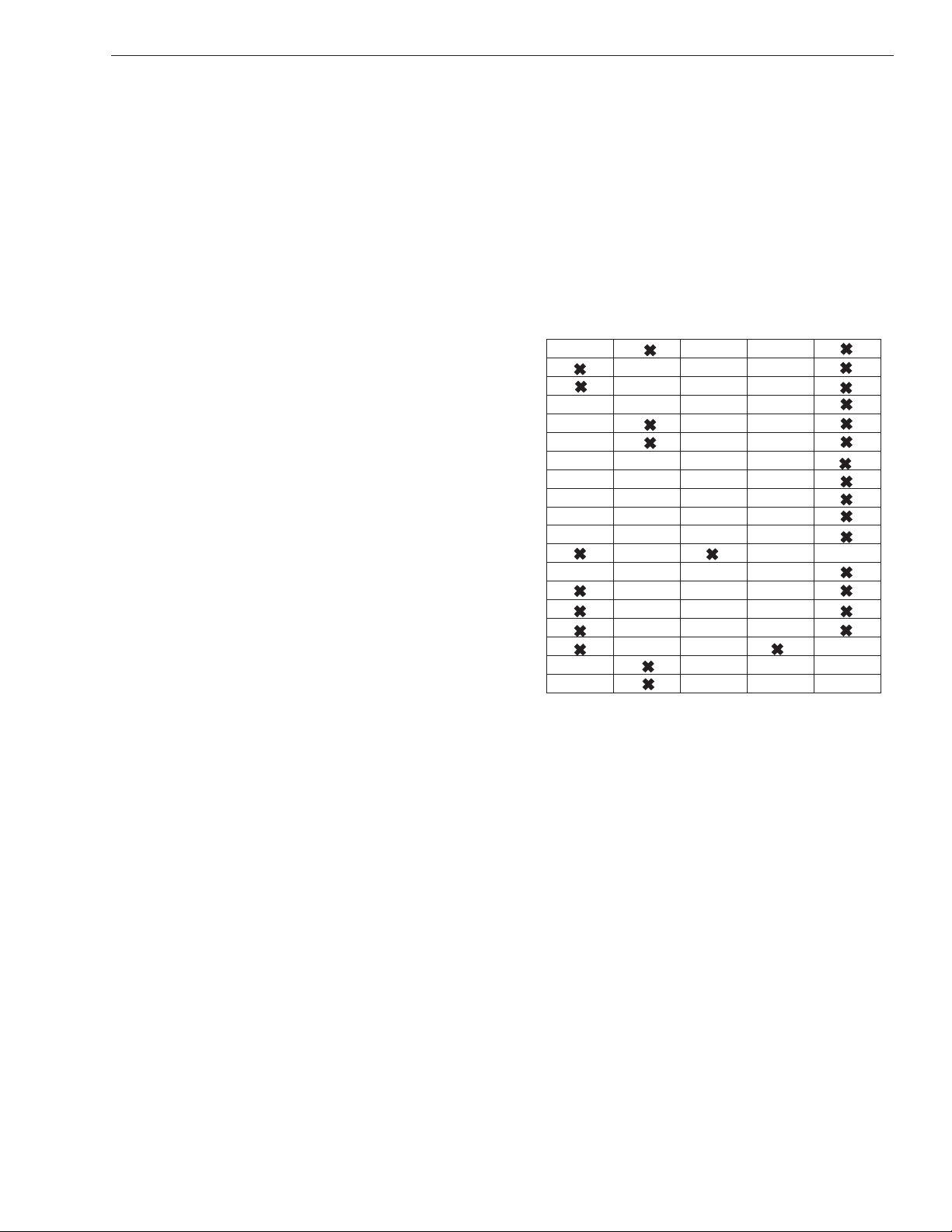

Maintenance

Note: Always employ safe practices in handling volatile or respiratory gases. Wear protective gear when installing, operating, or

servicing compressed gas apparatus. Never smoke, cause sparks or fire, or switch electrical equipment while in the presence of

volatile gases. MSDS are available for materials contained in disposable cartridges. Use approved methods for disposal of

cartridges. Never exceed ratings for this appliance. Always depressurize this appliance prior to any service activity. Do not direct

compressed gases at bodily openings, eyes, or skin. Do not attempt to regenerate disposable cartridges.

Replace FILTER CARTRIDGES

Lubricate O-RING SEALS in "Cartridge Holders"

Apply grease to CYLINDER HEADS AND FEET of "Cartridge Holders"

Replace O-RING SEALS in "Cartridge Holders"

Replace MICRONIC FILTER element and seal

Lubricate O-RING SEALS and THREADS in "Mechanical Filter"

Replace O-RING SEALS in "Mechanical Filter"

Replace O-RING SEALS in "Eyeball" Indicator

Replace SEALS in "Drain Valve" and "Vent"

Replace all SEALS in "Priority Valve"

Replace all SEALS in "Check Valves"

TEST "Relief Valve" operation

Replace all SEALS in "Isolation Valve"

Inspect all PIPING JOINTS for leakage

Inspect all SEAL JOINTS and COMPONENTS throughout appliance for leaks

Inspect CYLINDER wall conditions

Inspect FLUID LEVEL in "Gauges" and replace gauge if less than 2/3 full

Replace MECHANICAL FILTER unit at limits of repressurization cycle life

Replace CARTRIDGE HOLDERS at limit of repressurization cycle life

*Please refer to SUPPLEMENTS SECTION for details and procedures.

MAINTENANCE SCHEDULE

Anytime

service is

performed

Upon

Demand Monthly Every

3 Months

Every

6 Months

“HF SERIES” PURIFICATION APPLIANCE

10

Supplements

Supplement Inserts

These supplement pages are provided for additional detail on each component. Refer to them for replacement parts

and service information.

Lawrence Factor, Inc. is not responsible for the accuracy or reliability of these inserts.

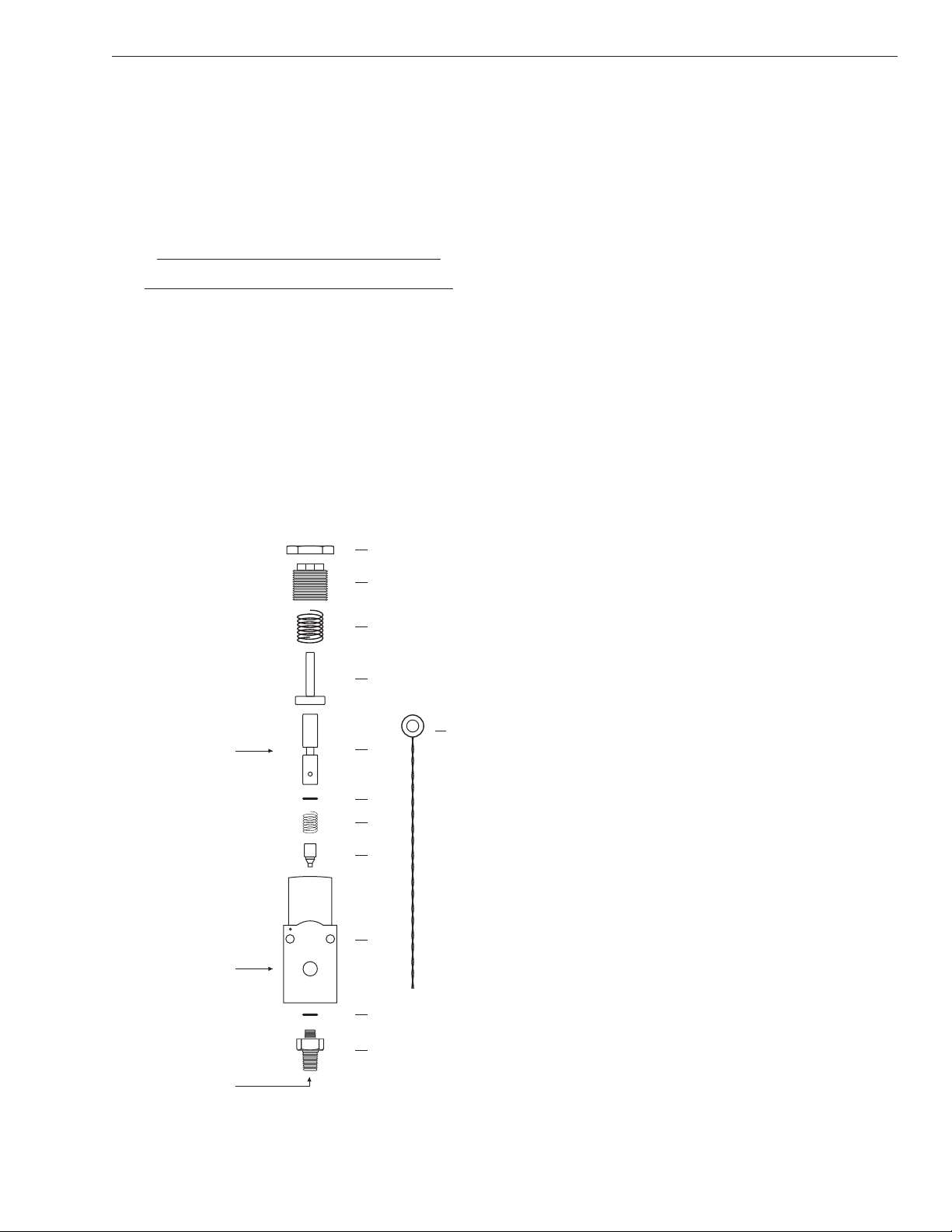

ASSEMBLY AND DISASSEMBLY GENERAL

Assembly and disassembly can be done by following the

drawings and parts list. Also refer to the repair section on the

opposite side of this sheet for disassembly sequence.

PARTS LIST - SERVICE KIT #RK-530210-HS

ITEM QTY DESCRIPTION

1 1 locking nut

2 1 adjusting screw

3 1 spring (red)

4 1 guide

5 1 piston

6 1 o-ring

7 1 counter spring

8 1 poppet

9 1 body SPECIFICATIONS

10 1 o-ring Maximum PSI 7000 PSI

11 1 seat / inlet fitting Adjustable PSI 1000 - 5000 PSI

12 1 safety wire (adj. 300 - 5000)

Flow capacity 75 SCFM

Inlet 1/4” NPT Male (stainless steel)

Outlet (3) 1/4” NPT Female

INSTALLATION

OPERATION

MAINTENANCE & REPAIR

The possible applications of the priority valve (a.k.a. back

pressure valve or pressure maintaining valve) are numerous

but typically serving to increase the efficiency of the

purification process. The valve maintains a constant high

pressure load on both the coalescor and adsorbent bed thus

increasing filter life as much as 400%..

This is a sturdy valve, designed to withstand harsh

environments and brutal usage. All internal wetted areas

are constructed of corrosion resistant materials including

stainless steel and hard-coat aluminum. An internal check

valve provides for non-return of the compressed gas. Three

(3) discharge ports conveniently turn this valve into a very

practical manifold block as well.

Two (2) mounting points are provided in cases where it is

desirable to affix or flush mount the valve. Use a suitable pipe

thread sealant such as TEFLON tape on all connections to the

inlet/outlet ports. It is suggested that a gauge be installed at

the outlet port on the face of the valve. This will accommodate

setting of the open point of the valve as well as downstream

pressure at any time. Any unused outlet ports may be

plugged. If the valve is installed in a piping line ensure that it is

adequately supported. WARNING: This product is NOT

approved for use in compressed oxygen environments.

The valve comes pre-tested and set at approximately

2000psi. This can be adjusted to your needs by loosening

the locking nut and then rotating the adjusting screw

clockwise to increase or counter-clockwise to decrease the

opening pressure.

In operation, the Priority Valve will maintain it's set pressure

upstream and regulate enough gas flow through the valve in

order to sustain this pressure.

Routine maintenance is generally not required. Under

extended or severe operation it is helpful to re-lubricate the

piston or replace the poppet. Refer to the blow up illustration

for order of assembly / disassembly. Reset the valve as

instructed above. In any case, the valve may be returned to

the factory for repair.

VL-530141-TG Priority Valve

1

2

3

4

5

6*

10*

7*

8*

9

11

*Included In

Service Kit

#RK-530210-HS

OUTLET

LUBRICATE

INLET

12

Priority Valve / Model VL-530141-TG

Cartridge Holder / Model PU-960003-AF

PU-960003-AF Holder

PRECAUTIONS: Follow safe engineering practices when installing or servicing this assembly. Depressurize system

and dis-connect electrical supplies prior to any service action. Do not over tighten cylinder head or foot. Do not exceed

working conditions set forth herein.

INSTALLATION: Mount to solid foundation in upright position (optional mounting kit is available). Gas flow through

unit must be in direction of arrow imprint on cylinder foot. Use appropriate thread sealant when making connections.

Apply nameplate, when installation is complete.

Use extreme care to prevent internal contamination since this unit has bee prepared for hyper clean environment.

SPECIFICATIONS

STYLE

MODEL NO

WORKING PRESSURE

MAXIMUM PRESSURE

TEST PRESSURE

BURST PRESSURE

SAFETY FACTOR

REPRESSURE CYCLE LIFE

MINIMUM TEMPERATURE

MAXIMUM TEMPERATURE

DIMENSIONS

PORT SIZE

CARTRIDGE SUPPLIED

Cartridge Holder

PU-960003-AF

2,000 - 5,000 PSI

5,000 PSI

7,500 PSI

20,000 PSI

4:1 ASME

15,000

0

40 F

0

120 F

3.750"OD x 33" H

No. 6-AN

Specified by application

CYLINDER HEAD

NOT AVAILABLE SEPARATELY

SEAL KIT

Part No. Sk-535306-BB

SEAL KIT

Part No. SK-535306-BB

CYLINDER

NOT AVAILABLE SEPARATELY

CYLINDER FOOT

NOT AVAILABLE SEPARATELY

Upon

demand

MAINTENANCE SCHEDULE

Replace FILTER ELEMENT

Lubricate O-RING SEALS

Apply grease to CYLINDER HEADS AND FEET

Replace O-RING SEALS

Inspect all PIPING JOINTS for leakage

Inspect all SEAL JOINTS and COMPONENTS for leaks

Inspect CYLINDER wall conditions

Replace CARTRIDGE HOLDER at limits of cycle life

Always employ safe practices in handling volatile or respiratory gases. Wear protective gear when

installing, operating, or servicing compressed gas apparatus. Never smoke, cause sparks or fire, or

switch electrical equipment while in the presence of volatile gases. MSDS are available for materials

contained in disposable cartridges. Never exceed ratings for this equipment.

Always depressurize this equipment prior to any service activity. Do not direct compressed gases at

bodily openings, eyes, or skin.

EVERY 15,000 CYCLES

Anytime

service is

performed

Monthly Every

3 months

Every

6 months

High Purity At High Pressure

4740 NW 157 Street, Miami Lakes, FL 33014 U.S.A.

Phone: (305) 430-0550 Fax: (305) 430-0864 Toll Free: (800) 338-5493

Email: [email protected] Website: www.Lawrence-Factor.com

Table of contents