OPERATING INSTRUCTIONS

8. OPERATING RULES

If the suction phase does not begin within 120 seconds, the pump will stop automatically,

and then will make two further attempts for another 120 seconds If the pump still will

not start, it will be necessary to troubleshoot the cause of the failure

Among the possible causes are: the suction line does not draw well or is leaky; the

priming opening is not closed properly; the suction height is excessive; air cannot come

out because the delivery tube is blocked; the suction line is not equipped with an Anti-

backflow foot valve or the pump body and the suction line were not completely filled

with water when the system was first put into operation

If the pump keeps starting and stopping and water is not turned on, the delivery tube or

the connection with the pump might be leaky In either case, an act as required The

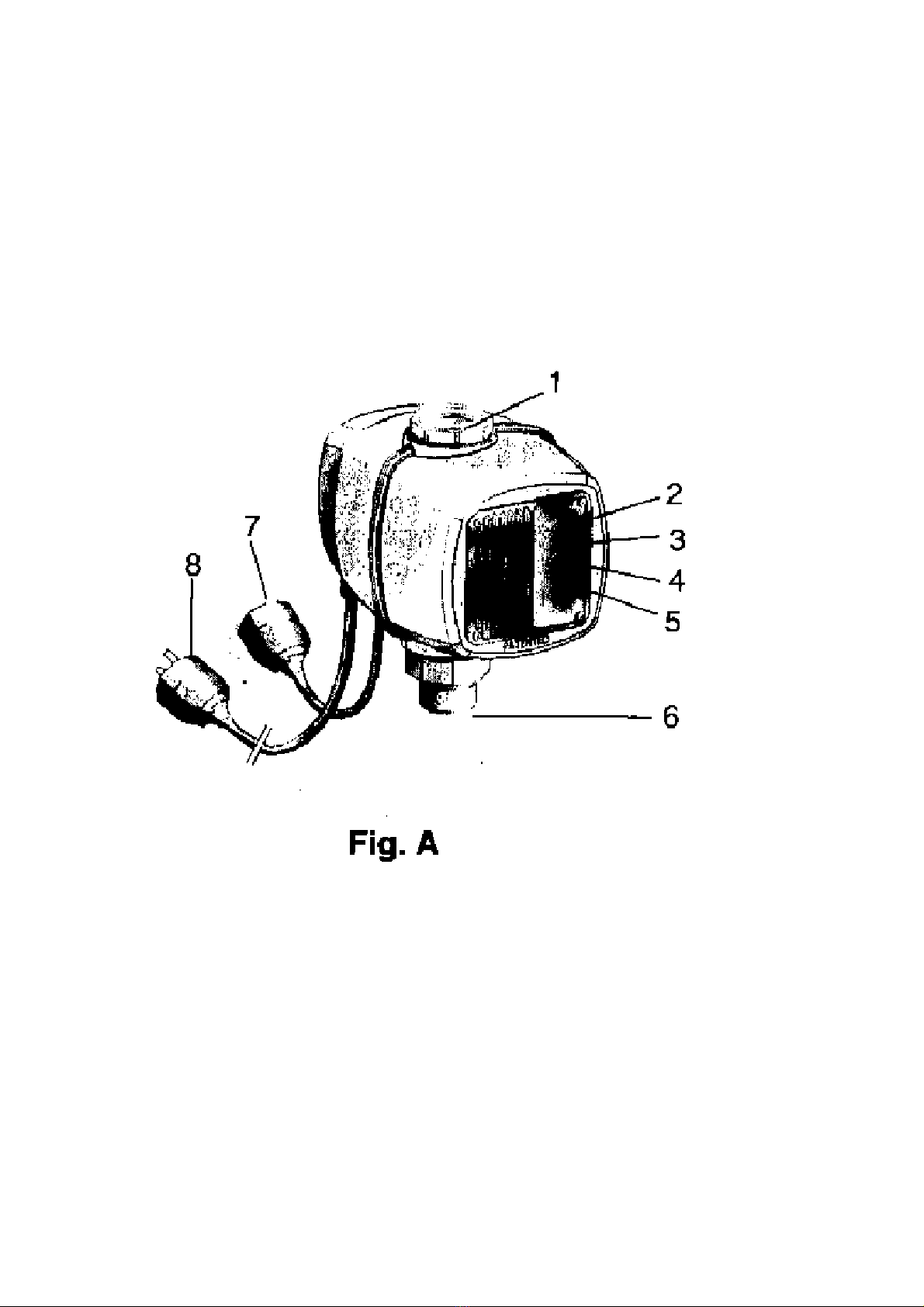

problem may also be due to a build-up of dirt inside the Hydrotronic If that is the case,

remove the Hydrotronic from the pump and rinse it thoroughly, for example with a strong

water jet from the inlet side (6)

9. WARRANTY

The warranty is valid for a period of 12 months from the date of purchase solely for

defects in materials or workmanship The warranty does not cover malfunctions due to

misuse or to failure to follow the instructions imparted by the Manufacturer

The warranty will be regarded as null and void if the plug or power cord have been

altered or tampered with (only the modifications mentioned in part 4 of this manual are

allowed) or if the Hydrotronic has been partly or totally disassembled

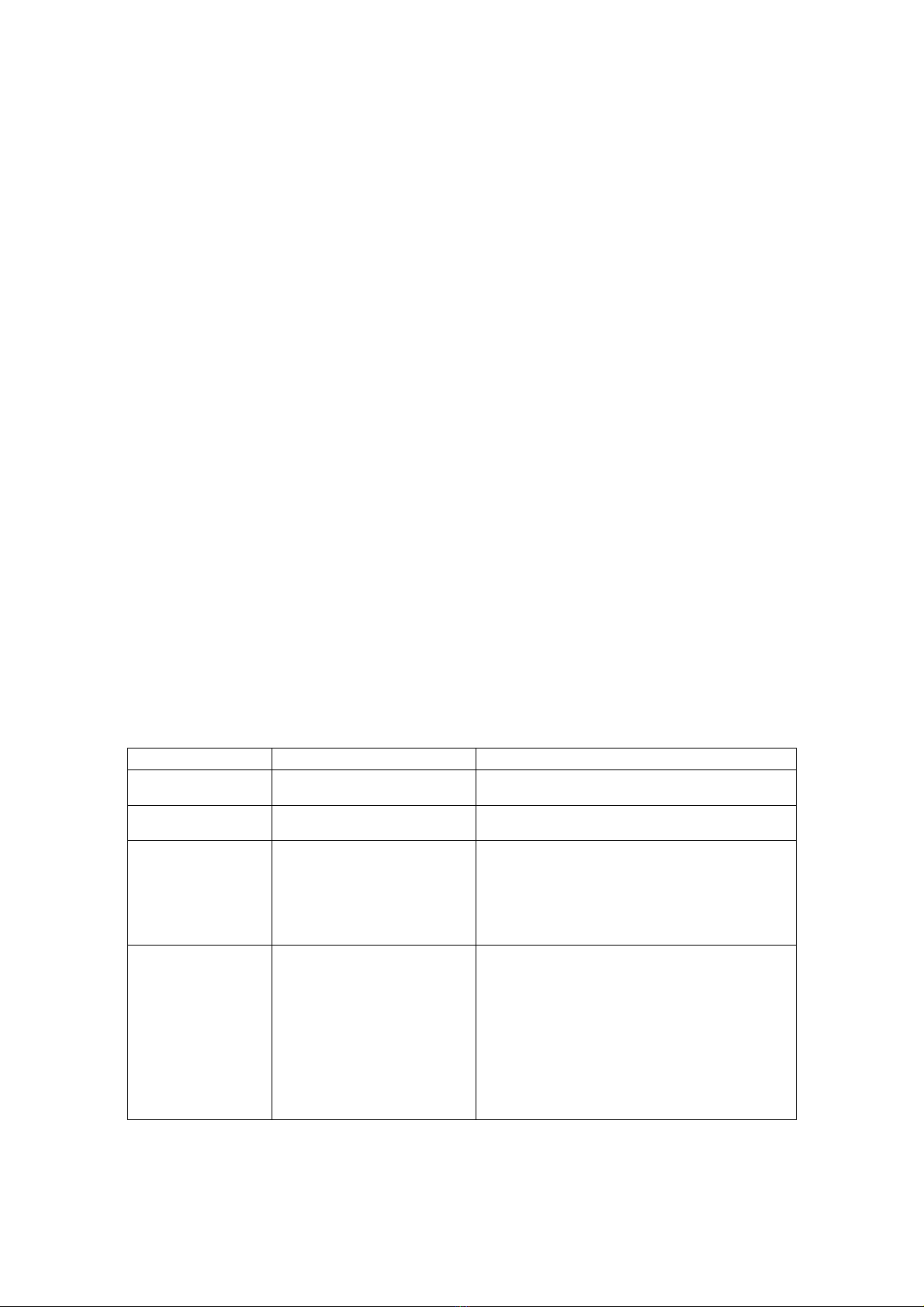

10. OPERATING PROBLEMS

PROBLEM CAUSE CORRECTIVE ACTION

Red LED (3)

blinks

No water Normal water flow must be restored

Red LED (3) stays

on continuously

No automatic reset attempts

left

Disconnect the power plug and then reconnect it

Pump keeps

starting and

stopping

1 The system is leaky

(unsealed)

2 Foreign materials inside the

Hydrotronic

1 Check the system and the connection with the

pump

2 Disconnect the power plug, remove the

Hydrotronic from the pump and rinse it

thoroughly by spraying water from the inlet side

(6) - i e using a garden hose

Pump dose not

work

1 The pump may be defected

2 The Hydrotronic may be

obstructed by foreign

materials or Limescale

(calcium)

Disconnect the Hydrotronic from the pump, both

hydraulically and electrically Try starting the

pump alone after connecting it to the mains If the

pump operates properly, inspect the Hydrotronic

from outlet hole (1), checking if the inner

impeller rotates freely If friction is encountered

Wash the Hydrotronic by filling it with vinegar or

other anti-scale product through outlet (1) It the

impeller turns freely contact the after-sales

service team