Festo SLG-8 Series User manual

Other Festo DC Drive manuals

Festo

Festo ERMS Parts list manual

Festo

Festo DGOL-16 PPV-A B Series User manual

Festo

Festo DGC-HD Series User manual

Festo

Festo ELGL-LAS User manual

Festo

Festo DGO-xxx-A-B series User manual

Festo

Festo DRRD-12 User manual

Festo

Festo DDLI-25 User manual

Festo

Festo ELCC-TB-KF Parts list manual

Festo

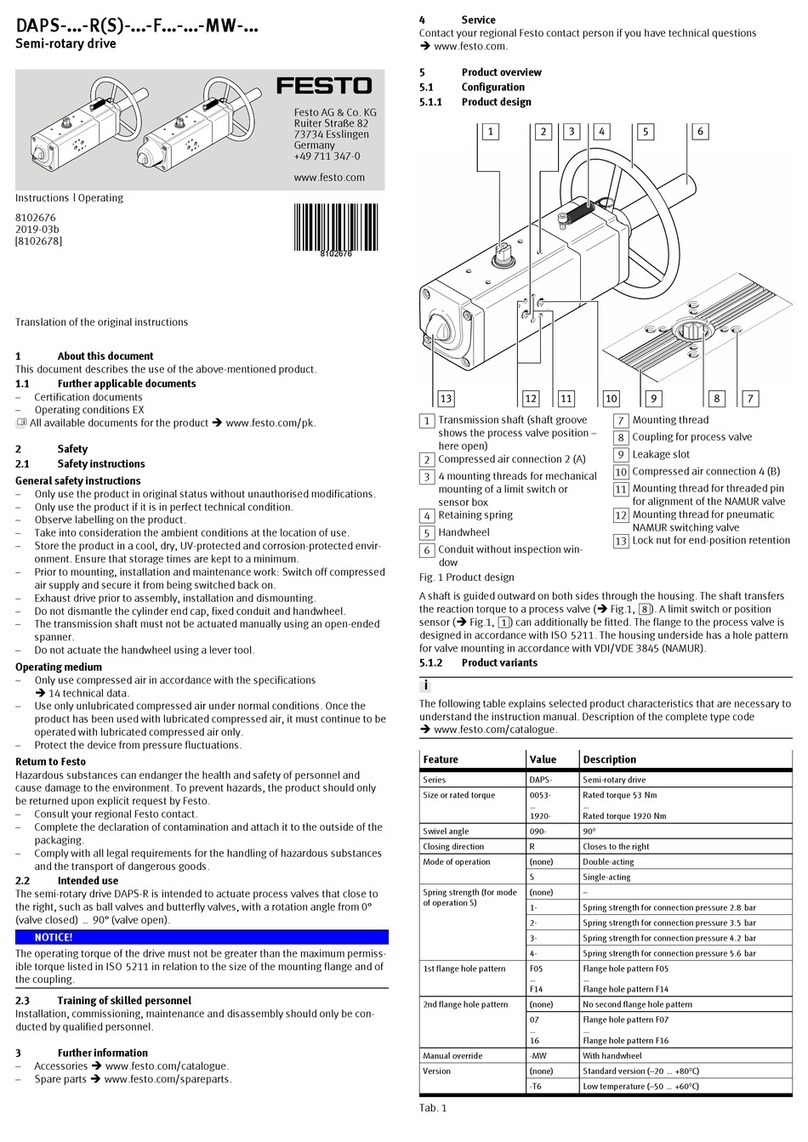

Festo DAPS-...-R-...-F...-...-MW Series User manual

Festo

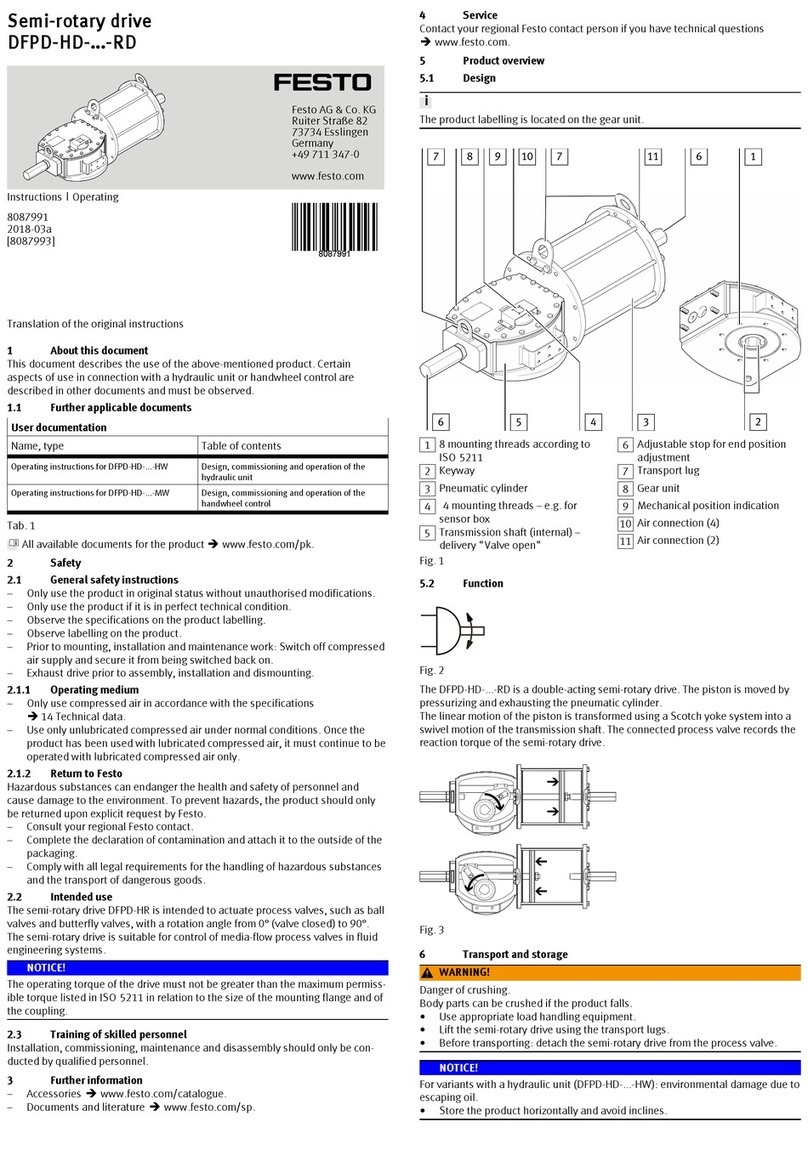

Festo DFPD-HD-RD Series Parts list manual

Festo

Festo EMCA-EC-67 CO Series Operating and installation instructions

Festo

Festo DGC-K Series Setup guide

Festo

Festo DFPI ND2P-E-NB3P Series User manual

Festo

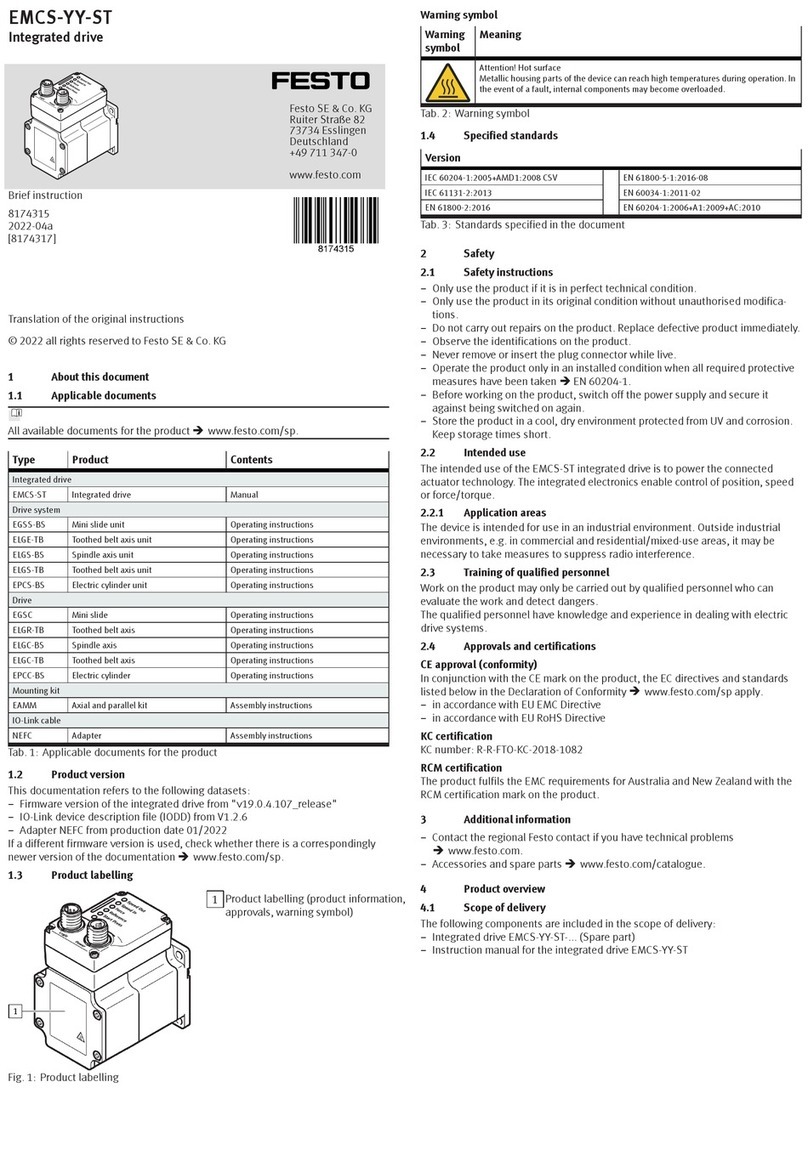

Festo EMCS ST Series Reference guide

Festo

Festo DSR-10-180-P User manual

Festo

Festo DFPD-Series User manual

Festo

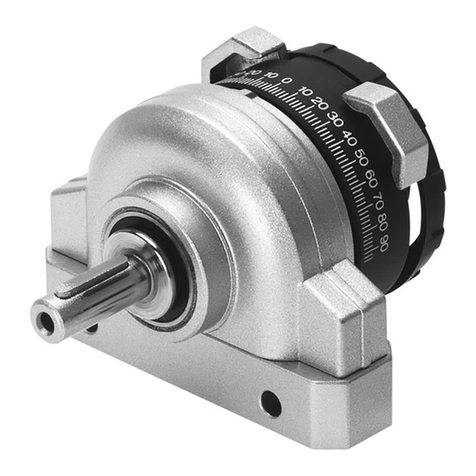

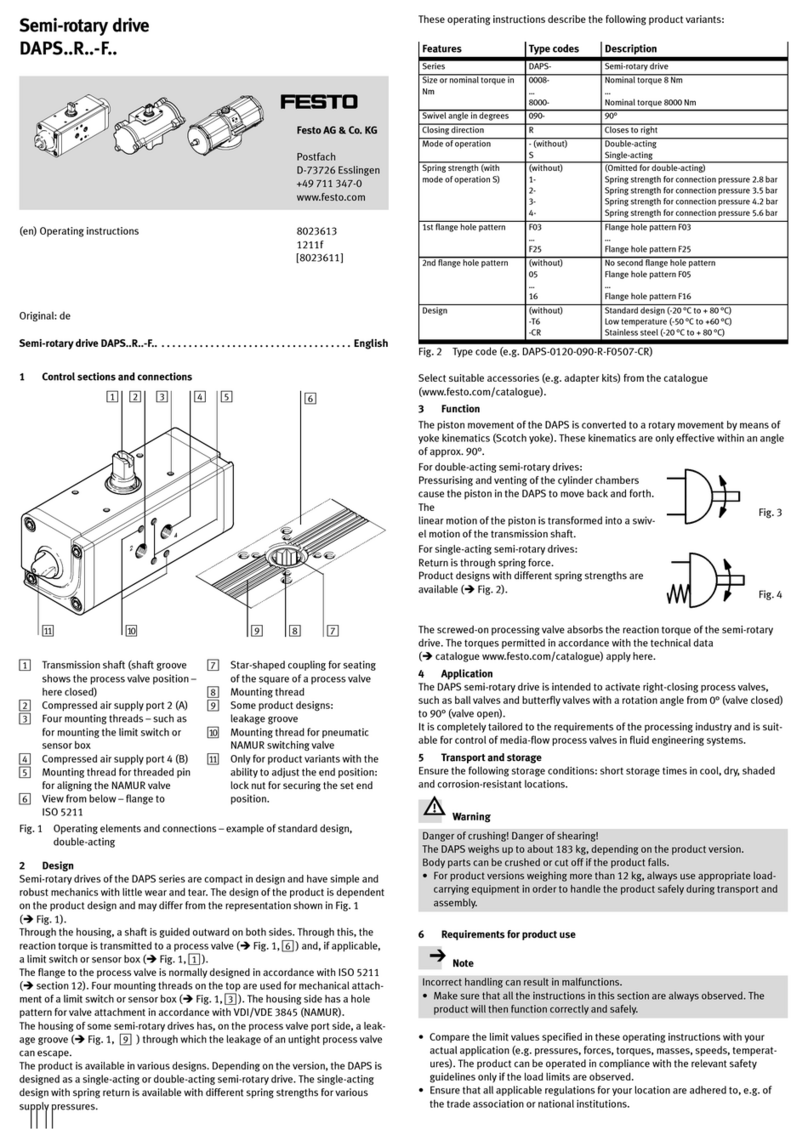

Festo DAPS..R..-F Series User manual

Festo

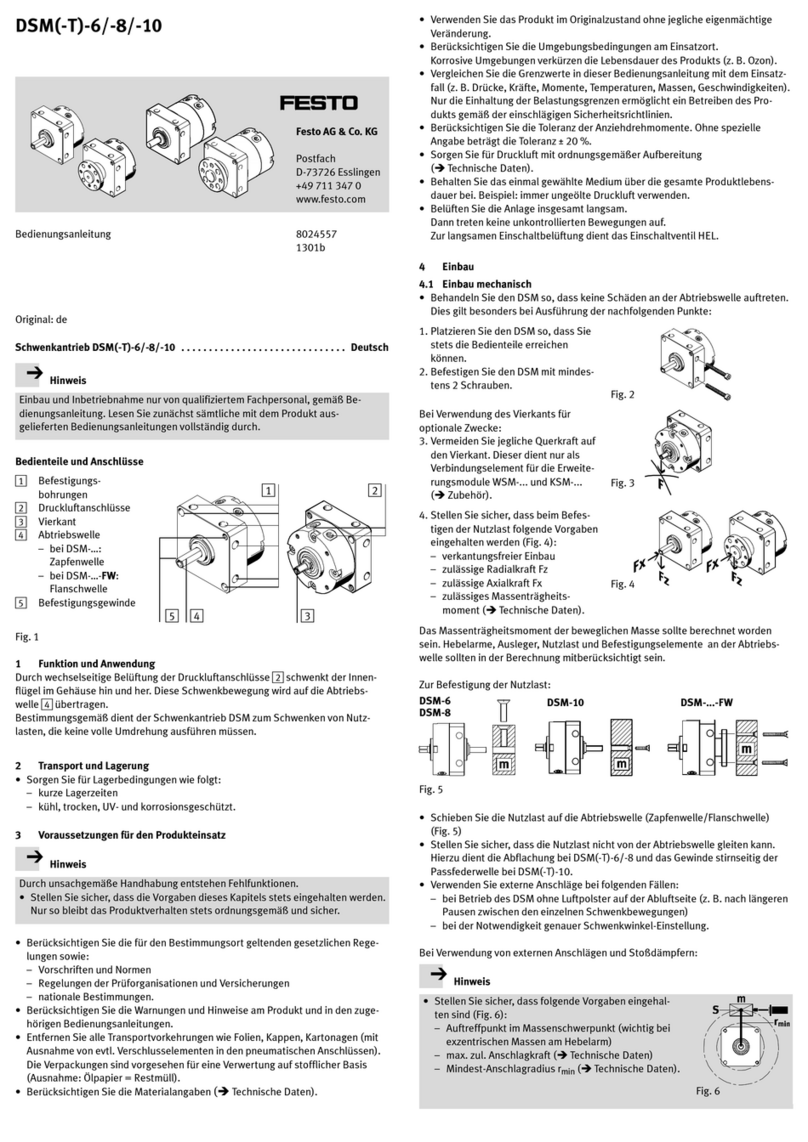

Festo DSM-6 User manual

Festo

Festo DNCM POT Series User manual

Festo

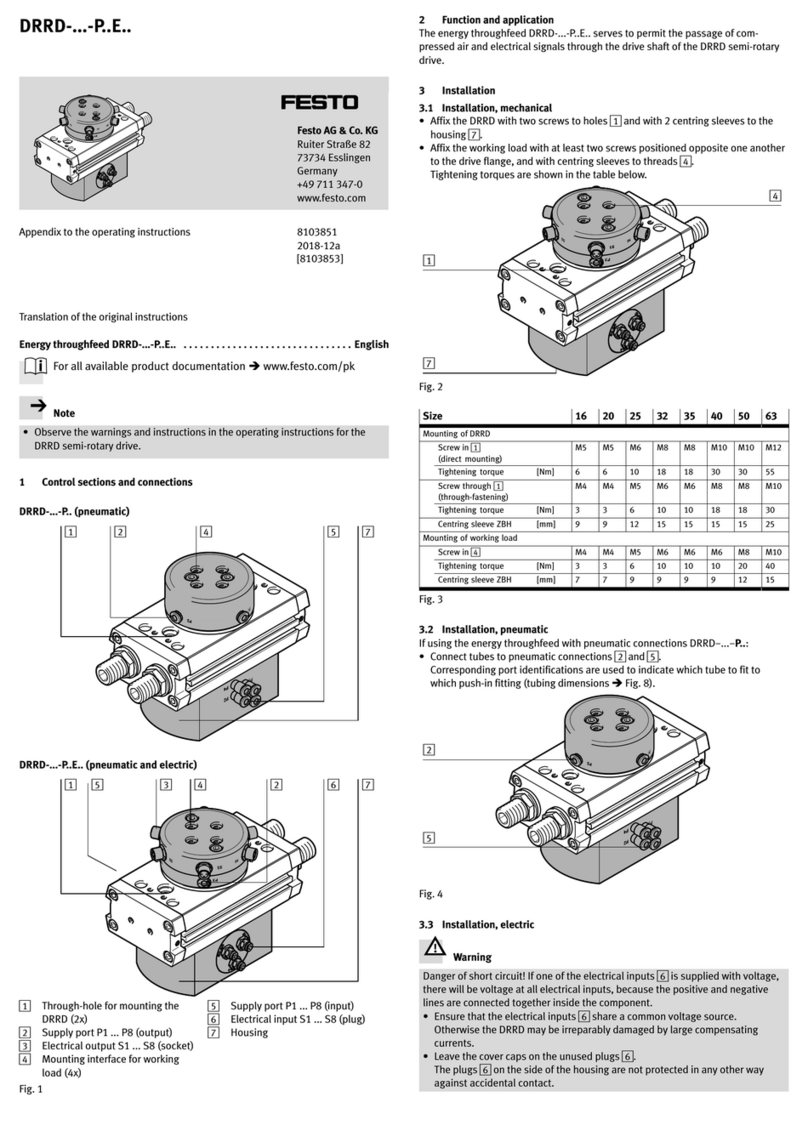

Festo DRRD-...-P..E Series User manual