Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

CiA®, EtherCAT®, EtherNet/IP®, PI PROFIBUS PROFINET® are registered trade

marks of the respective trademark owners in certain countries.

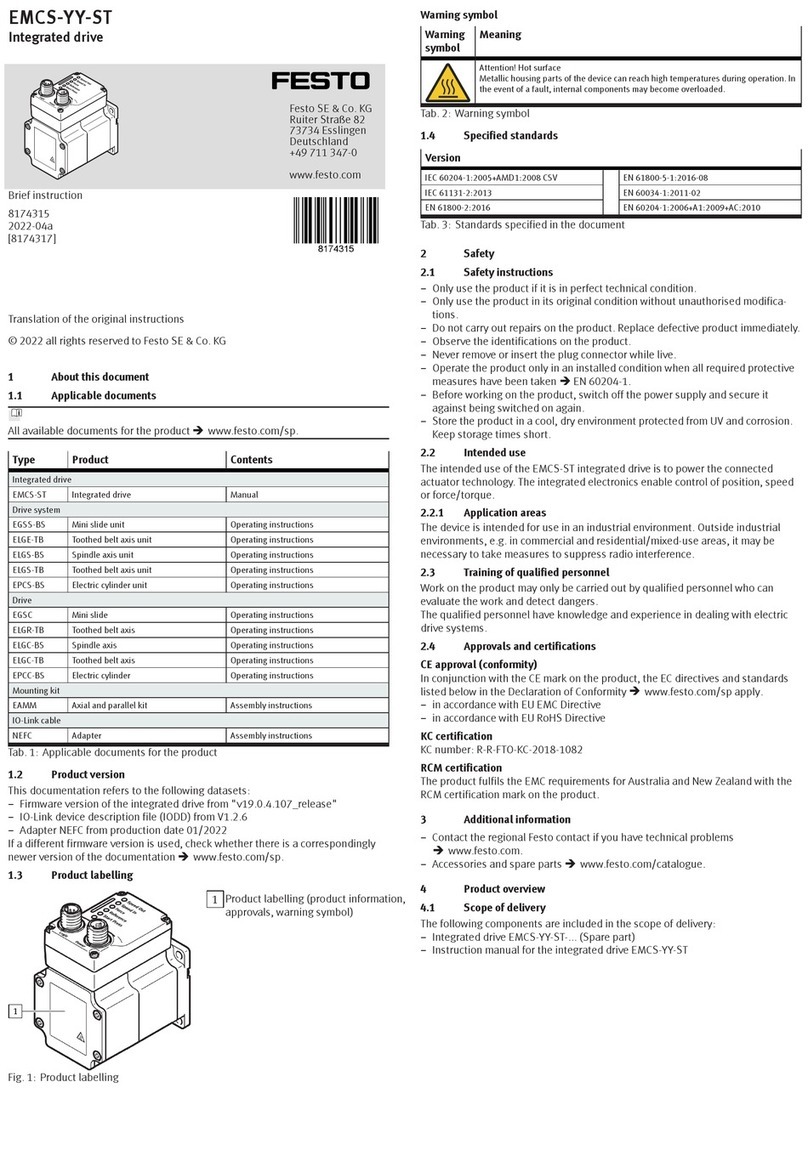

1 Applicable documents

All available documents for the product èwww.festo.com/sp

User documentation for the product

Manual

EMCAECSY…

Device and functional description;

Mounting, installation, commissioning and diagnostics

Manual

EMCAECS1…

Description of the “safe torque off” safety function (Safe torque

off/STO)

Manual

EMCAECCHP…

Description of device profile FHPP (Festo Handling and Positioning Pro

file)

Help for the FCT plugin

EMCA

Online help for the Festo Configuration Tool (FCT) for commissioning

and parameterisation

Special documentation

EMCAEC_UL…

Requirements for operating the product in the USA and Canada in

accordance with certification by Underwriters Laboratories Inc. (UL)

Tab. 1

2 Safety

– Always observe the safety instructions and warnings in the documentation of

the product and the other components.

– Before mounting and installation work, switch off supply voltage and secure it

against being switched on again. Do not switch on the supply voltage until

mounting and installation work is complete.

– Never remove or insert a plug when the motor controller is powered.

– Handhabungsvorschriften für elektrostatisch gefährdete Bauelemente einhal

ten.

– Do not enable the closedloop controller until the drive has been profession

ally installed and fully parameterised.

– Do not carry out repairs on the device. If it is defective, replace the device.

– Do not loosen any screws except for the 4 screws on the housing cover.

WARNING!

Risk of injury from touching hot surfaces.

Contact with housing can cause burn injuries. This can frighten people and cause

them to act in an unpredictable manner. This can lead to other forms of secondary

damage.

• Avoid unconscious touching of the housing.

• Inform operating and maintenance staff about the possible hazards.

• Before maintenance work: Let the drive cool down to below 40°C.

WARNING!

Fast rotating motor shaft with high torque.

Contact with the motor shaft can cause burn injuries and abrasions.

• Ensure that the rotating motor shaft and components attached to it cannot be

touched.

WARNING!

Gas formation with fire risk.

If cleaning agents come into contact with the hot surface of the drive, gases may

be formed and may ignite.

• Allow the drive cool down to room temperature before starting cleaning.

2.1 Intended use

The product is intended for the actuation and control of electromechanical drives.

The product is intended for installation in a machine.

Use exclusively:

– In perfect technical condition

– In original condition without unauthorised modifications; only the extensions

described in the documentation supplied with the product are permitted

– Within the limits of the product defined by the technical data

– in an industrial environment

Outside of industrial environments, measures may need to be implemented for

radio interference suppression, e.g.in commercial and residential/mixedused

areas.

2.2 Intended use of the STO function

The STO function "safe torque off" in accordance with EN 6180052 is intended

to shut down the torque of the integrated motor. The STO function prevents unex

pected startup of the integrated motor. The STO function may only be used in

applications in which the specified safety characteristics are sufficient.

Safety characteristics

The product’s STO function fulfils requirements for the following characteristic

safety values:

– PL dl/cat. 3 in accordance with ISO 138491 (Performance Level/PL)

– SIL 2 in accordance with EN 6180052 (Safety Integrity Level/SIL)

– SIL CL 2 in accordance with IEC 62061 (Claim Limit/CL)

The achievable safety level depends on the other components used to implement

a safety function.

To protect against unintended motor startup, the controller of the product must

be activated via connection [X6] with the category required for the application in

accordance with ISO 138491, e.g.via an external safety relay unit.

Qualification of the specialist technicians (requirements for staff)

The product may be commissioned only by a person with electrical engineering

qualifications who is familiar with the following:

– installation and operation of electrical control systems

– the applicable regulations for operating safetyrelated systems

– the applicable regulations for accident prevention and occupational safety

– the documentation for the product:

Diagnostic coverage (DC) for the safety function

Diagnostic coverage is determined by including the product in the control chain

and the measures implemented for the diagnostics. In order to achieve the spe

cified diagnostic coverage, the status of the feedback contact must be evaluated

by the control system every time the STO function is requested. If a potentially

dangerous malfunction is detected during diagnostics, appropriate measures

must be taken to maintain the safety level.

The device cannot detect a cross circuit in the input circuit by itself.

• If required, use a safety relay unit with detection of shorts across contacts.

2.3 Foreseeable misuse of the STO function

The following examples of foreseeable misuse are among those not approved as

intended use:

– bypassing the STO function

– use in applications where switching off can result in hazardous movements or

conditions.

The STO function is not sufficient as the sole safety function for drives that are

subject to permanent torque or force (e.g.suspended loads, vertical axes).

2.4 Obligations of the operator for the safety function

The implemented safety function must be subjected to a regular and documented

performance test by a specialist during the period of use of the machine.

The frequency of these tests must be determined by the machine operator based

on the specifications of the machine manufacturer.

– Check the EMCA at least once a year.

3 Requirements for product use

– Provide the complete product documentation to the following personnel:

– the design engineer and the installer of the machine or system

– the personnel responsible for commissioning

– Keep the documentation somewhere safe throughout the entire product life

cycle.

– Ensure compliance with the specifications in this documentation. Also

observe the information in the documentation for the other components and

modules, e.g.axial kit, gear unit, actuator, lines.

– Comply with all of the legal regulations that are applicable for the installation

site, as well as the following documents:

– Regulations and standards

– Regulations of the testing organisations and insurers

– National specifications

For correct and safe use of the STO function:

– Conduct a risk assessment for your machine.

– Comply with the specified safety characteristics è 10 Technical data.

8127103

EMCA-EC-67-...-EC/-EP/-PN

Integrated drive

8127103

202003b

[8127105]

Brief instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com