4iCONgrade, Table of Contents

Table of Contents

In this manual Topic Page

1 Product Overview 6

1.1 Product Description and Features 6

1.2 Getting Started 11

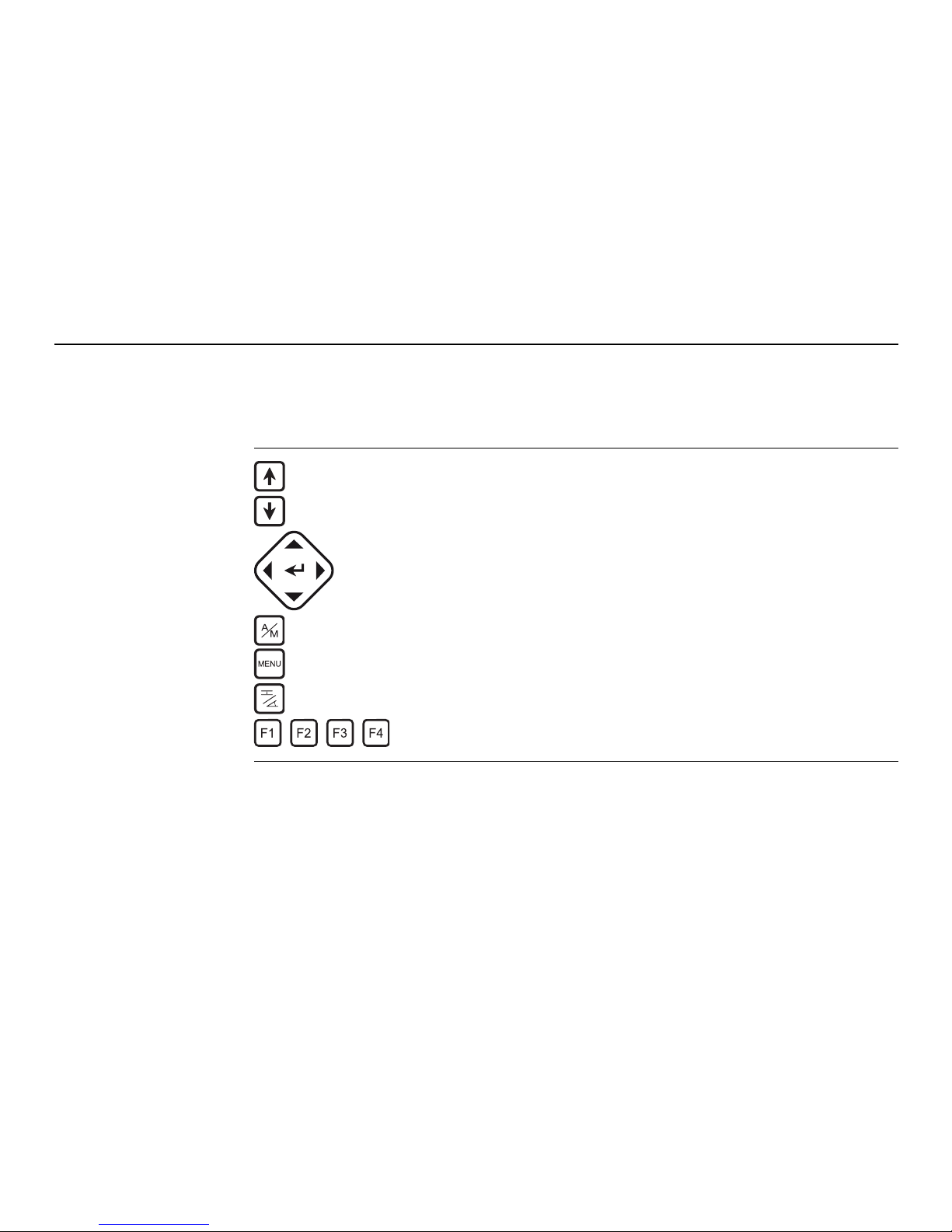

1.3 Sensor Setup Keys 13

2Operation 16

2.1 Pre-power up checks 16

2.1.1 Best operation practice for Grader Systems 17

2.1.2 Mast orientation 18

2.1.3 No Articulation, circle center shift, or wheel lean on Grader 19

2.1.4 Grader blade cushioning off 21

2.1.5 No blade rotation on Dozer 22

2.2 Select the Input Source 23

2.3 Setting a Reference Height 26

2.4 Using the MUS1300 Tri-Sonic Sensor 28

2.4.1 Installation and Set Up Tri-Sonic Sensor 32

2.4.2 Operation with the Tri-Sonic Sensor 34

2.4.3 Swap Function 37

2.5 Using the Laser Sensor 39

2.6 SP14 Sensor 41

2.7 3D Sensors 43

2.8 Setting the Value for Gain and Deadband 45

2.9 Sensor Calibration Wizard 48

2.10 Machine Setups 55