Your New Leigh Dovetail Jig

Congratulations! You now own a most useful and versatile

dovetailing tool.The Leigh Superjig Dovetail Jig will help you

cut an infinite variety of joints, and all of its major functions

are described in detail in this manual, plus there's a slide-out

Quick Reference Guide underneath the jig. A very helpful

DVD is also included, but the manual is essential reading.

We recommend that you first assemble and mount the jig,

carefully following the instructions in the first section of the

manual. Then read the rest of the manual, following along

with the basic functions and principles of operation, before

you try to do any actual joinery routing. By all means, cut a

few practice joints in scrap boards before you use the jig to

rout a precious hardwood work piece!

If you have any questions that are not answered in the manual,

please call the Leigh customer support line*.

But remember: “If at first you don’t succeed, read the instruc-

tions!”

*See Appendix IV – Customer Support

Important! Inches and Millimetres

The Superjig can be ordered in inch or metric versions.They're

identical except for the calibration scales. This Leigh English-

language user guide show measurements in both inches and

millimetres, with “inches” first, followed by “millimetres” in

square brackets.

Example:

3⁄4"x 51⁄2"x8" [20x140x200mm]

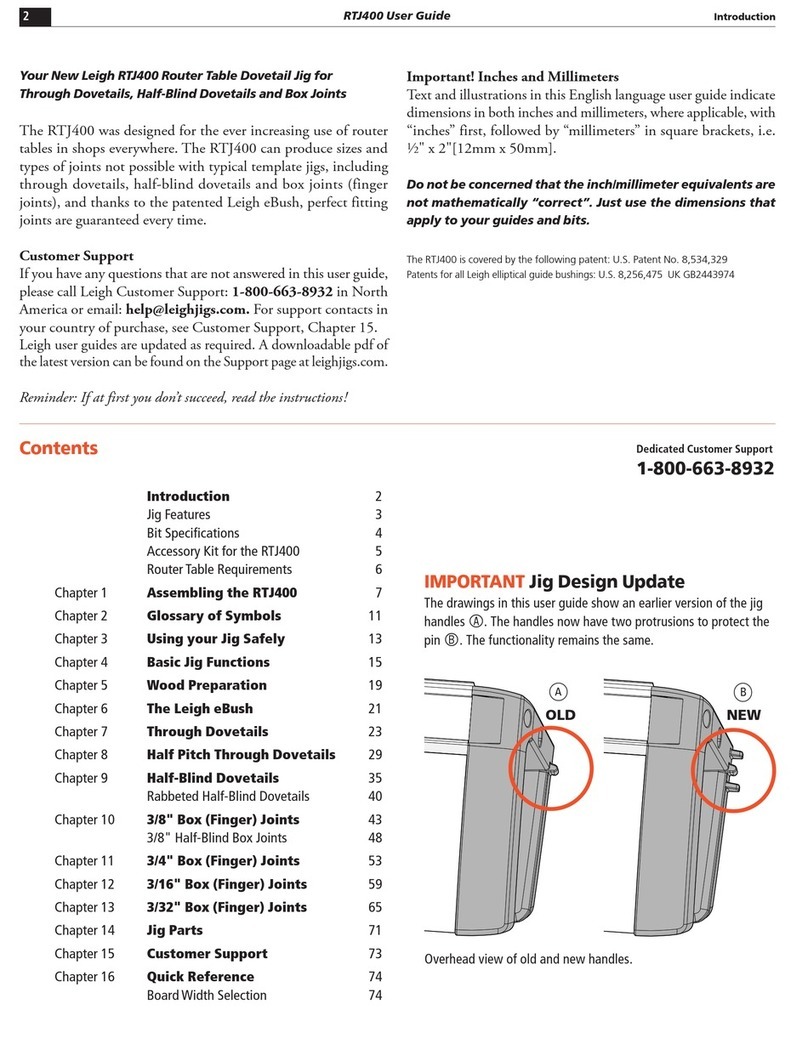

Do not be concerned if the inch/millimetre equivalents are not

exact. Just use the dimensions which apply to your jig.

Where finger assembly scales overlay an illustration, the “inches”

scale will be at the top, the “millimetres” scale will be at the

bottom. Only the front “active” half of the scales are illustrated.

For clarity, setting positions are indicated with a red line in the

manual only. On the jig, the lines are black.