22

RTJ400 User Guide

Introduction

Dedicated Customer Support

1-800-663-8932

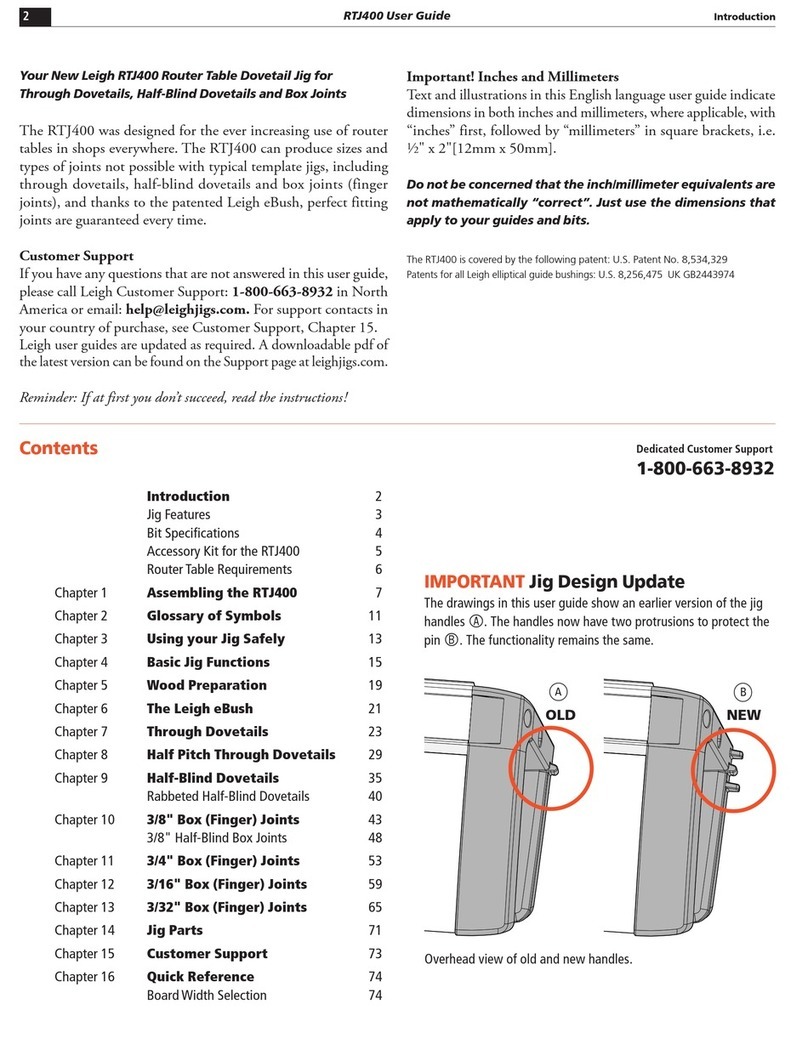

Your New Leigh RTJ400 Router Table Dovetail Jig for

Through Dovetails, Half-Blind Dovetails and Box Joints

The RTJ400 was designed for the ever increasing use of router

tables in shops everywhere. The RTJ400 can produce sizes and

types of joints not possible with typical template jigs, including

through dovetails, half-blind dovetails and box joints (finger

joints), and thanks to the patented Leigh eBush, perfect fitting

joints are guaranteed every time.

Customer Support

If you have any questions that are not answered in this user guide,

please call Leigh Customer Support: 1-800-663-8932 in North

your country of purchase, see Customer Support, Chapter 15.

Reminder: If at first you don’t succeed, read the instructions!

Important! Inches and Millimeters

Text and illustrations in this English language user guide indicate

dimensions in both inches and millimeters, where applicable, with

“inches” first, followed by “millimeters” in square brackets, i.e.

1⁄2" x 2"[12mm x 50mm].

Do not be concerned that the inch/millimeter equivalents are

not mathematically “correct”. Just use the dimensions that

apply to your guides and bits.

The RTJ400 is covered by the following patent: U.S. Patent No. 8,534,329

Patents for all Leigh elliptical guide bushings: U.S. 8,256,475 UK GB2443974

Contents

Introduction 2

Jig Features 3

Bit Specifications 4

Accessory Kit for the RTJ400 5

Router Table Requirements 6

Chapter 1 Assembling the RTJ400 7

Chapter 2 Glossary of Symbols 11

Chapter 3 Using your Jig Safely 13

Chapter 4 Basic Jig Functions 15

Chapter 5 Wood Preparation 19

Chapter 6 The Leigh eBush 21

Chapter 7 Through Dovetails 23

Chapter 8 Half Pitch Through Dovetails 29

Chapter 9 Half-Blind Dovetails 35

Rabbeted Half-Blind Dovetails 40

Chapter 10 3/8" Box (Finger) Joints 43

3/8" Half-Blind Box Joints 48

Chapter 11 3/4" Box (Finger) Joints 53

Chapter 12 3/16" Box (Finger) Joints 59

Chapter 13 3/32" Box (Finger) Joints 65

Chapter 14 Jig Parts 71

Chapter 15 Customer Support 73

Chapter 16 Quick Reference 74

Board Width Selection 74