F1 Template Assembly,

Mounting and Template Alignment

1Mount the D4 jig firmly to a bench as per

its instructions. Remove the dovetail finger

assembly.

9Move the combined template and bar to the

left until the right side of the outer 1⁄4"[8mm]

opening touches the block ➀. Taking care to not

move the template assembly, tighten the scale

screws at the left end ➁. Remove the block.

Remove the pin and slide the template left. Tighten

the scale screw at the right end ➂. Your Leigh F1

is now ready for use. ■

8Trim off the end of an 8"[200mm) long per-

fectly straight block at about 30 degrees.

Slide the combined bar/template to allow the

block to protrude into the last socket of the

1⁄4"[8mm] comb. Clamp the block with its vertical

edge tight against the right hand side stop.

7Discard the plastic shipping plug from the

centre hole. Align the template so that the

right hand hole ➀ of the three central template

holes aligns with the hole in the bar. Insert the

template pin ➁, gently twisting and pushing the

tapered pin into the hole until it is fully seated.

6Tighten the scale bracket screws ➁, but do

not tighten the scale bar screws ➀ yet. 5Loosen the fence knobs ➀ and move the fence

on the template toward you as far forward as

possible and with the fence scale reading the same

at both ends ➁. Then tighten the fence knobs ➀.

4Slide the template assembly onto the jig

support brackets with the 1⁄2" and 1⁄4"[10

and 8mm] combs toward you and lower it gently

onto the D4 jig’s spacer board ➃ (D4 UserGuide

1-1). Make sure the scale reading is the same

on both scales, say on the 1"[25mm] mark, then

tighten the thumb screws ➂.

3Loosen the two scale bar set screws ➀,

the two fence bracket screws ➁, and the

two scale thumb screws ➂ at both ends of the

template.

Joining Tradition with Today

ATTENTION D4, D3, D1258 Jig Owners.

Nov 2005

© Leigh Industries Ltd. All rights reserved.

This pdf publication may be downloaded and stored on a computer and printed, viewed, and freely distributed for operational guidance and evalu-

ation purposes. This document supplements the full User Guide publication for the Leigh tool and may refer to and depend on information in other

parts of the tool’s User Guide for completeness. Except as provided herein, no part of this document may be reproduced, sold, published or modified

without the prior written permission of Leigh Industries Ltd. [Nov2005]

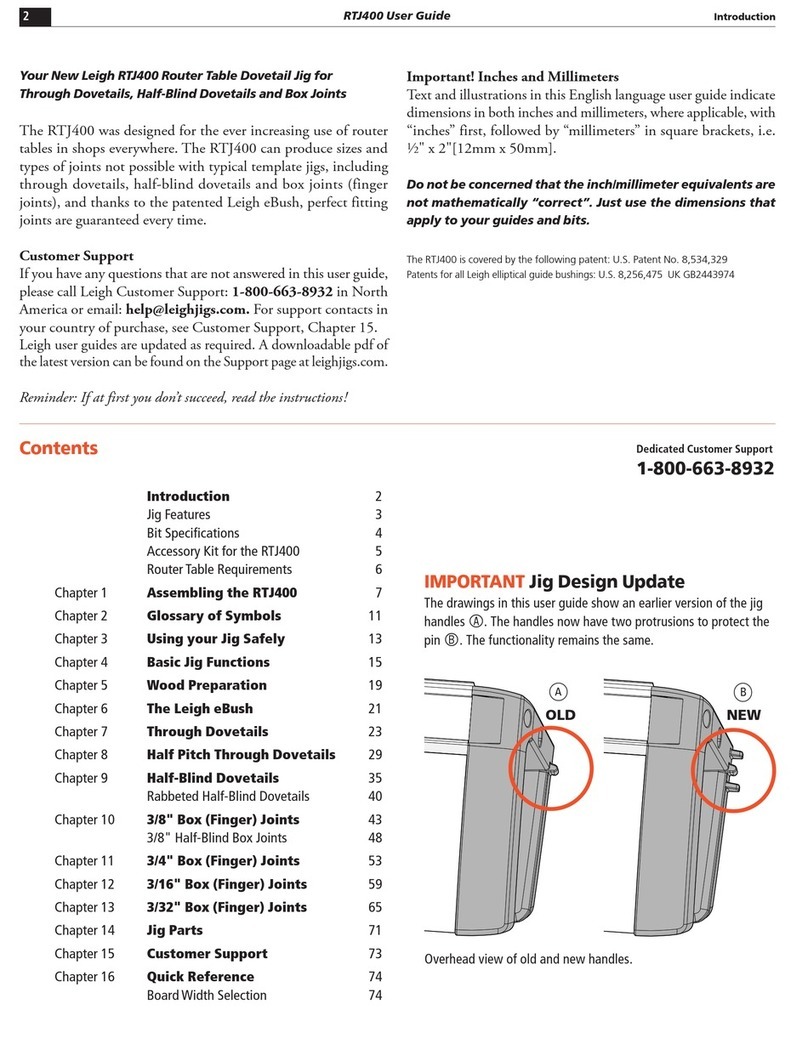

This addendum replaces all of Chapter 1 of the F1

User Guide when using the classic Leigh D4 Jig Body.

2Ensure that the side stops are precisely

11⁄2"[38mm] in from each end of the jig extru-

sions ➀. This will position them 241⁄8"[613mm]

apart ➁ centred on the jig ➂.

!Note: These parts are

no longer required for

setting up the F1 Template.

They are not included with

the Template package, and

can be ignored if you already

received them with your jig.