OPERATION

NEVER run pump dry! Running pump dry may dam-

age seals, causing leakage and flooding! Fill pump

with water before starting motor.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge

pipes.

3. RELEASE ALL PRESSURE from pump and piping

system.

Fire and burn hazard. Modern motors run at

high temperatures. To reduce the risk of fire, do not allow

leaves, debris, or foreign matter to collect around the

pump motor. To avoid burns when handling the motor, let

it cool for 20 minutes before trying to work on it. An auto-

matic internal cutoff switch protects the motor from heat

damage during operation.

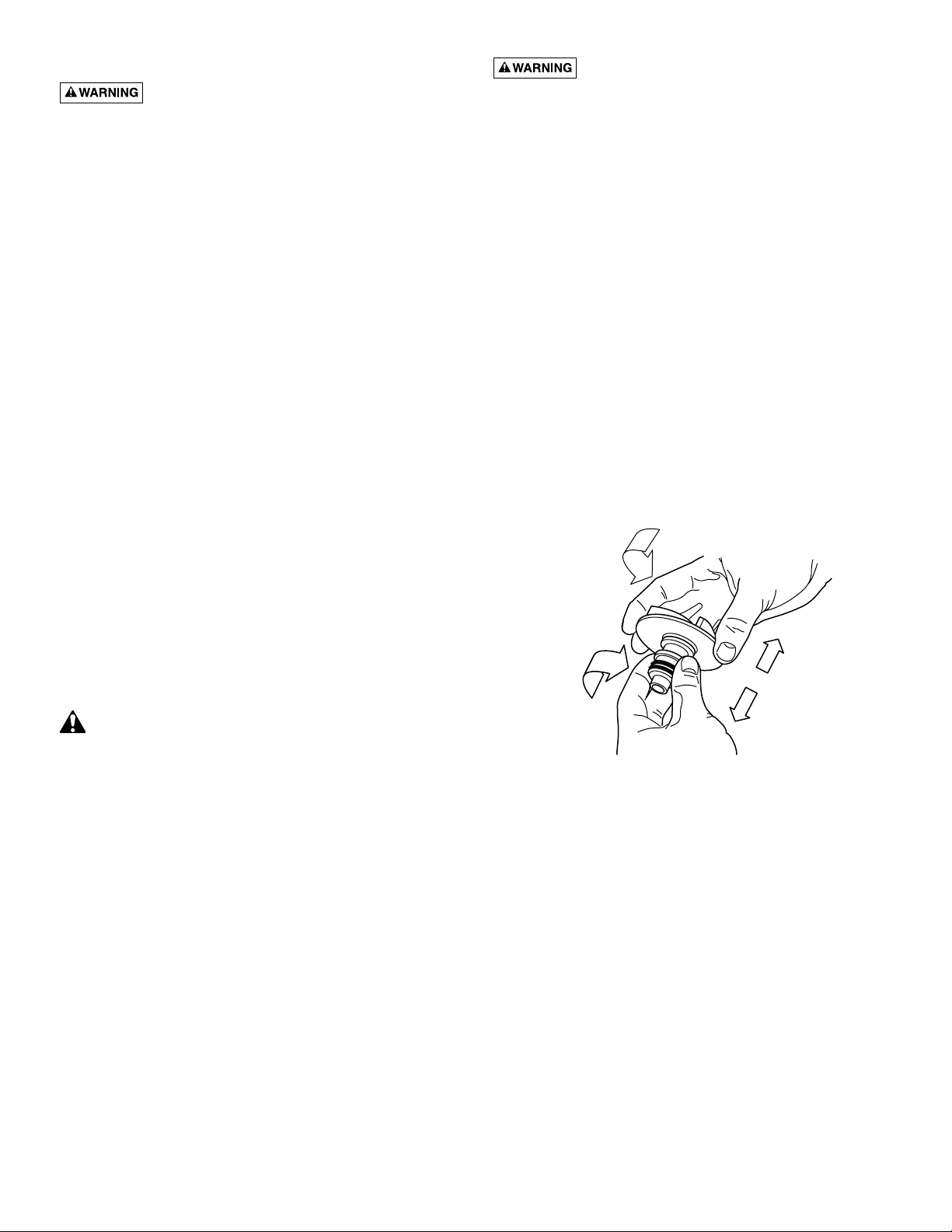

Do not block pump suc-

tion! To do so with body

may cause severe or fatal

injury. Small children using

pool must ALWAYS have close

adult supervision!

NOTICE: Do not block pool

return. To do so may flood area

causing damage to equipment

and water damage to surround-

ing area.

Priming Pump:

Open valves before starting

system.

Release all pressure from filter, pump, and piping system;

see the filter owner’s manual.

In a flooded suction system (water source higher than

pump), pump will prime itself when suction and discharge

valves are opened.

Pool Water:

Keep water level at least two inches above bottom of skim-

mer opening when system is not in use. Failure to do so

can allow air to enter system, causing pump to lose its

prime.

Keep pool water “balanced”. Maintain the water pH

between 7.2 and 7.6.

Do not use or allow the use of the pool by anyone

using alcohol or drugs. The effects of hot water, alco-

hol and/or drugs can cause dizziness and falling, loss of

consciousness, or heart attack.

Storage/Winterizing:

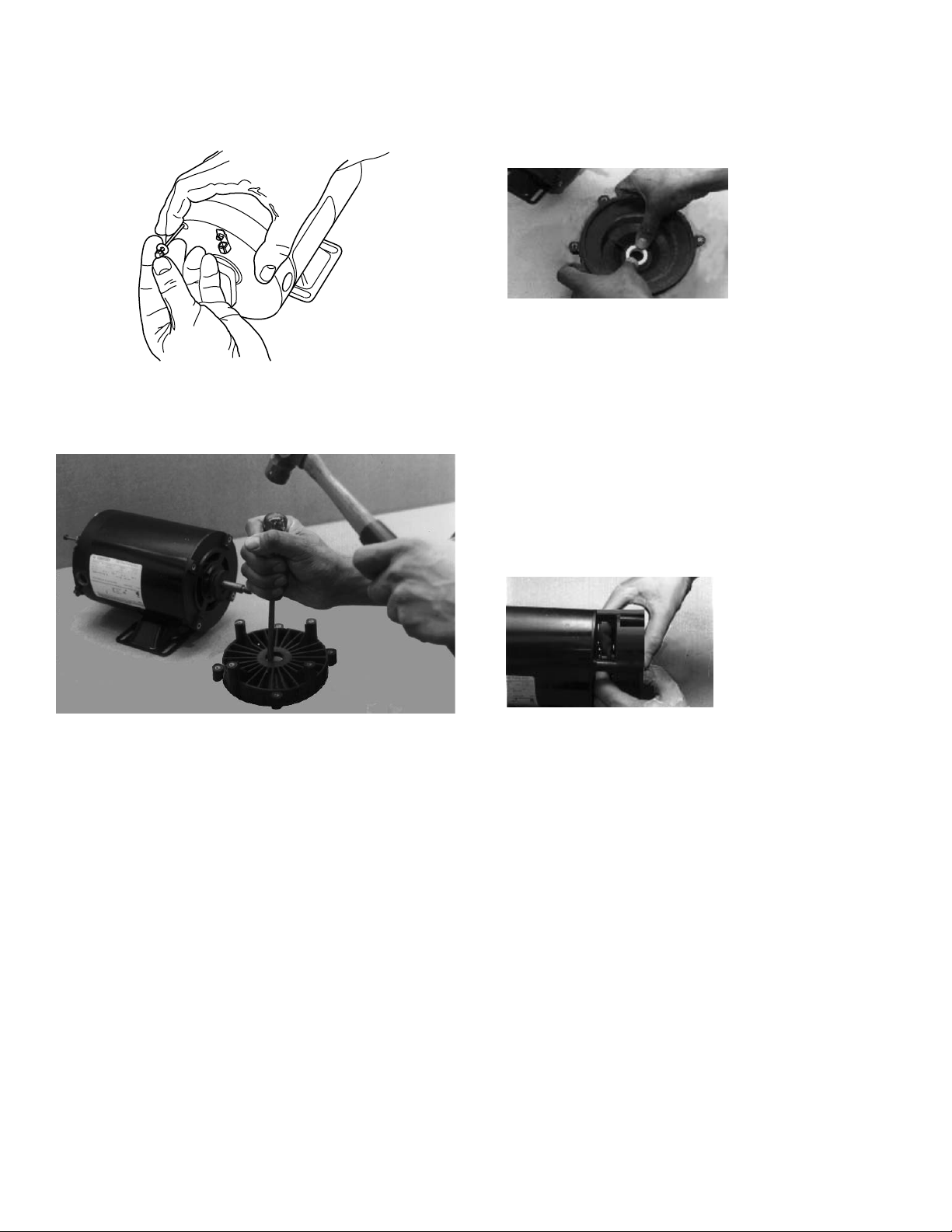

Explosion hazard. Purging the system with

compressed air can cause components to explode, with

risk of severe injury or death to anyone nearby. Use only

a low pressure (below 5 PSI), high volume blower when air

purging the pump, filter, or piping.

To prevent damage to components from fumes, store

chemicals away from pump. If possible, store chemi-

cals in another room.

NOTICE: Drain pump! Allowing pump to freeze will dam-

age pump and void warranty!

NOTICE: Do not use anti-freeze solutions (except propy-

lene glycol) in your pool system. Propylene glycol is non-

toxic and will not damage plastic system components;

other anti-freezes are highly toxic and may damage plastic

components in the system. Propylene glycol is widely used

as antifreeze in recreational vehicles.

Drain all water from pump and piping when expecting

freezing temperatures or when storing pump for a long

time (see instructions below).

Keep motor dry and covered during storage.

To avoid condensation/corrosion problems, do not cover

or wrap pump with plastic.

For outdoor/unprotected installations:

1. Pump down water level below all inlets to pool.

2. Enclose entire system in a weatherproof enclosure.

3. To avoid condensation/corrosion damage, allow ven-

tilation; do not wrap system in plastic.

4. Use a 40% propylene glycol/60% water solution to

protect pump to -50°F.

5. Follow pool manufacturer’s directions for storage of

pool.

5

Hazardous suction.

Can trap hair or

body parts, causing

severe injury

or death.

Do not block suction.