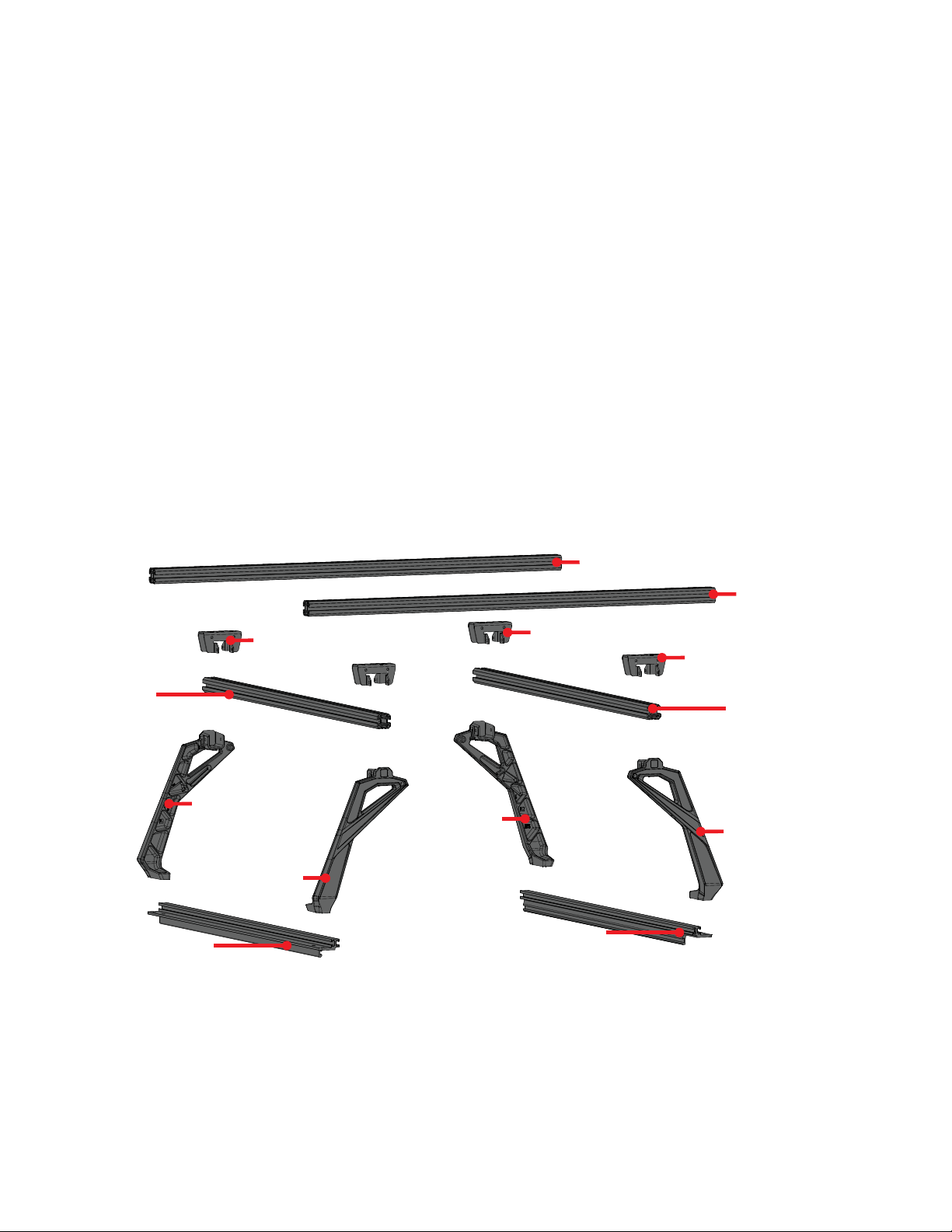

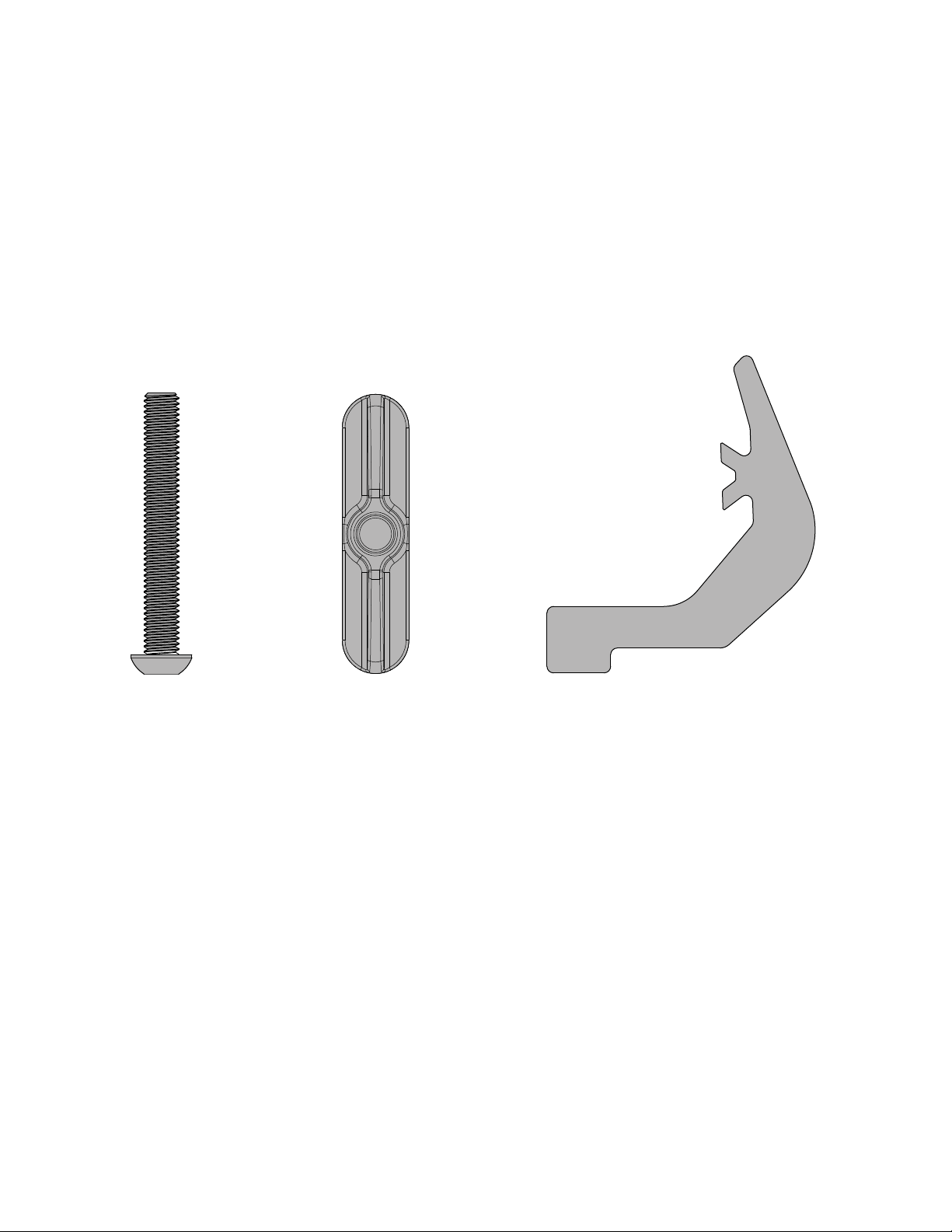

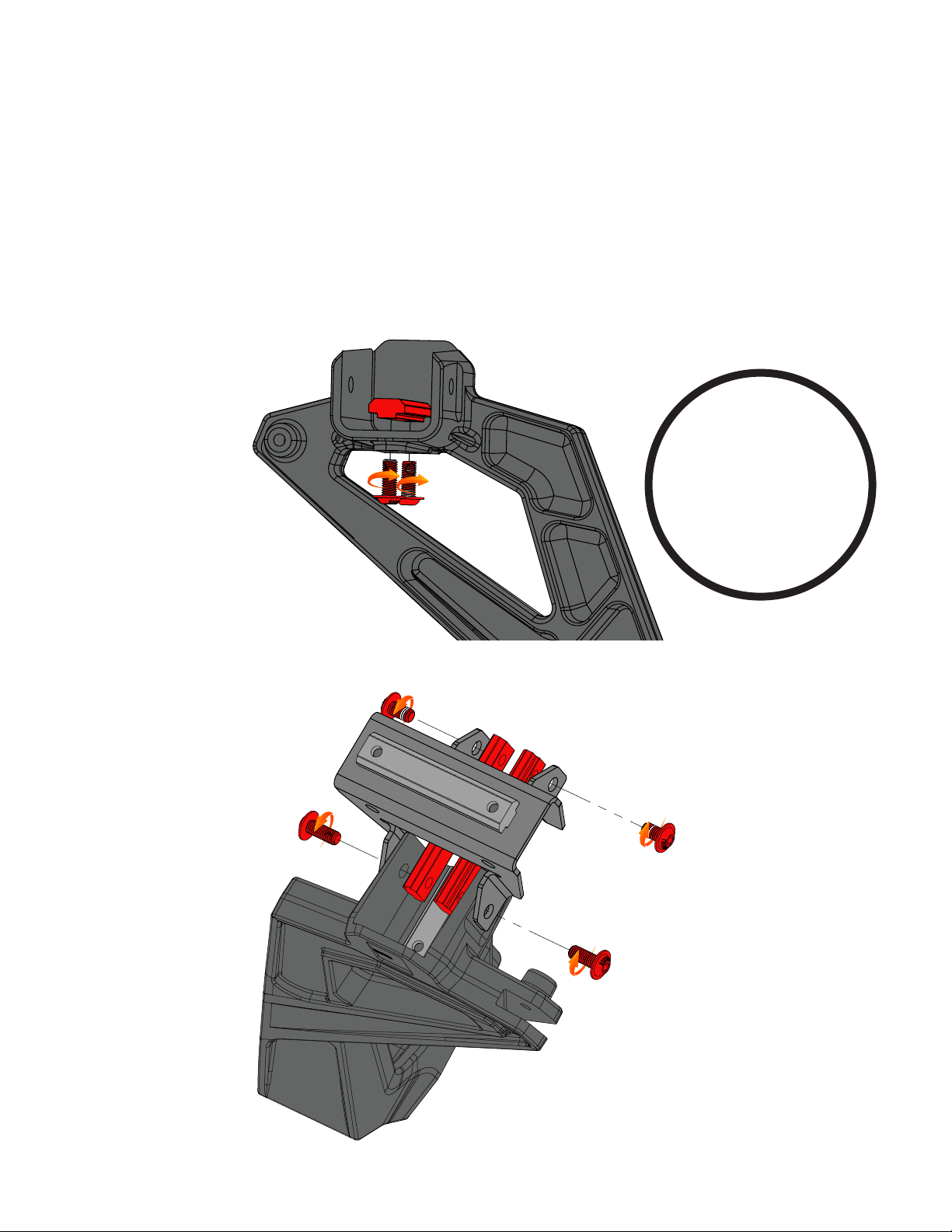

Leitner ACS FORGED Programming manual

Other Leitner Automobile Accessories manuals

Leitner

Leitner FORD SUPER DUTY 2017-UP User manual

Leitner

Leitner ACS ROOF User manual

Leitner

Leitner ACS FORGED User manual

Leitner

Leitner TRAKLOK gear pod XL User manual

Leitner

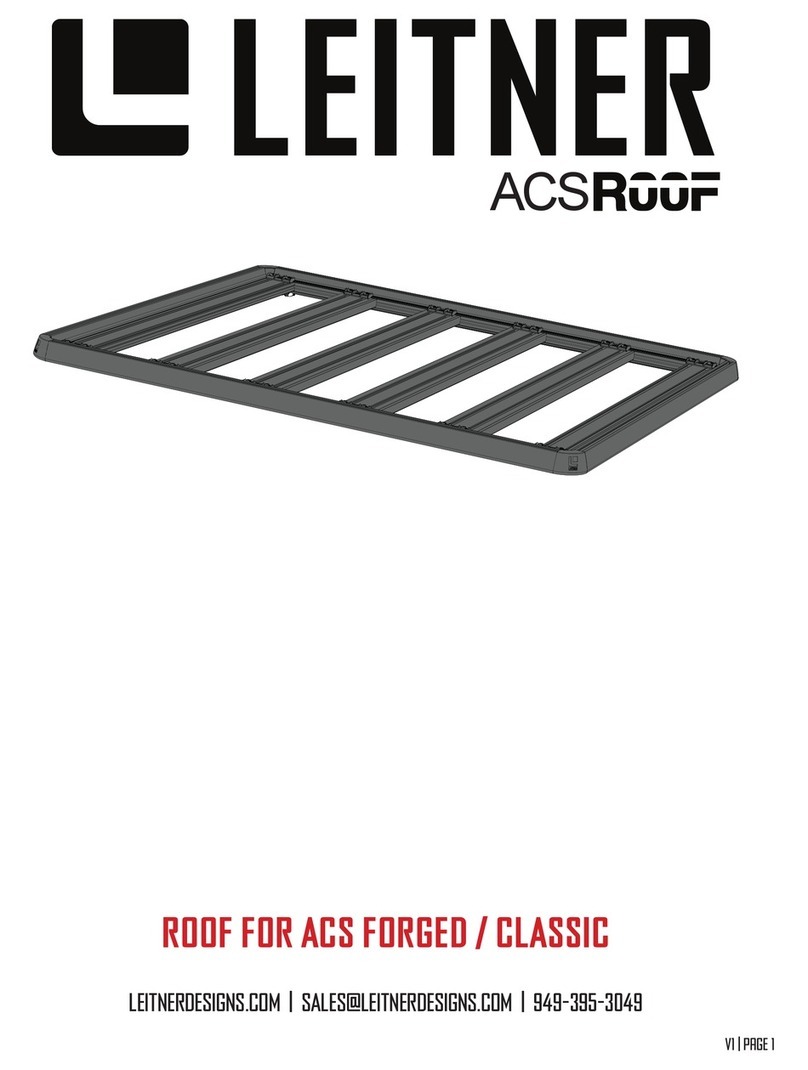

Leitner ACS ROOF ROOF FOR ACS FORGED / CLASSIC User manual

Leitner

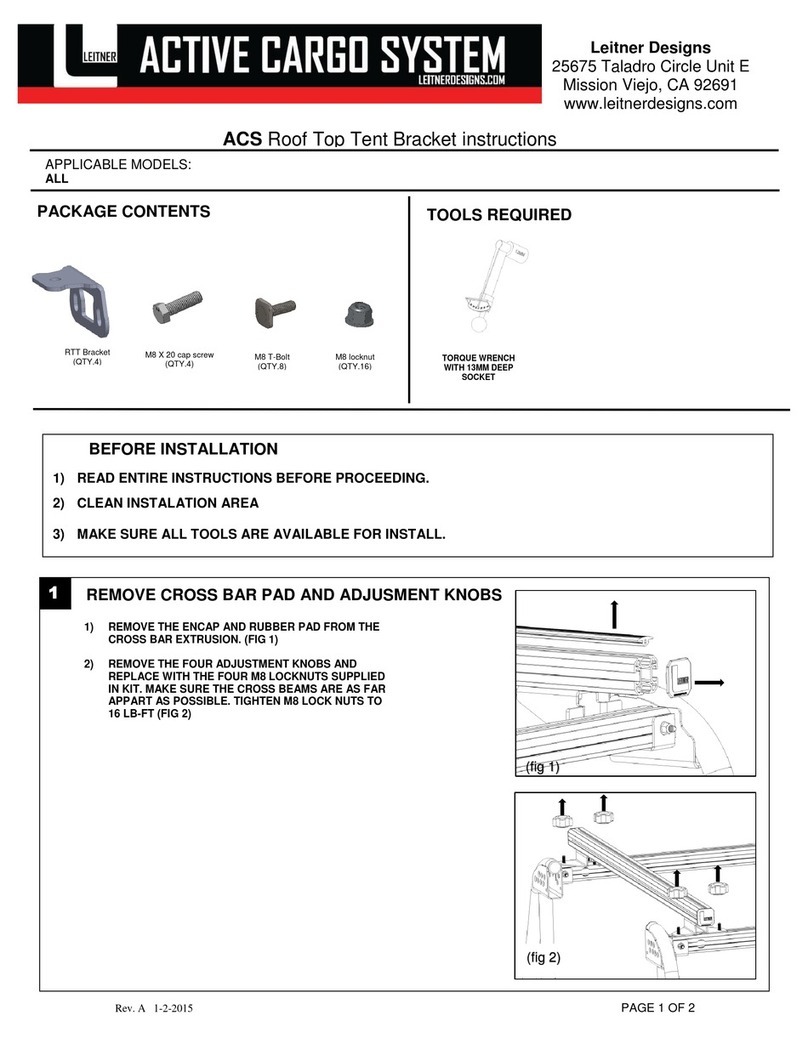

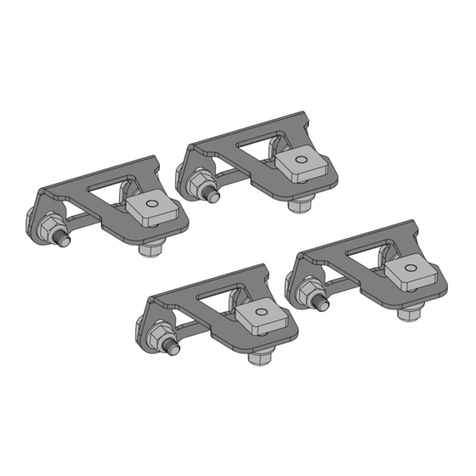

Leitner ACS ROOF GEARPOD roof User manual

Leitner

Leitner ACS TONNEAU Programming manual

Leitner

Leitner ACS User manual

Leitner

Leitner 00-JBRTT-1389 Programming manual

Leitner

Leitner TRAKLOK gear pod User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction