2 WELGER RP 202 •RP 220 •RP 302 •RP 320

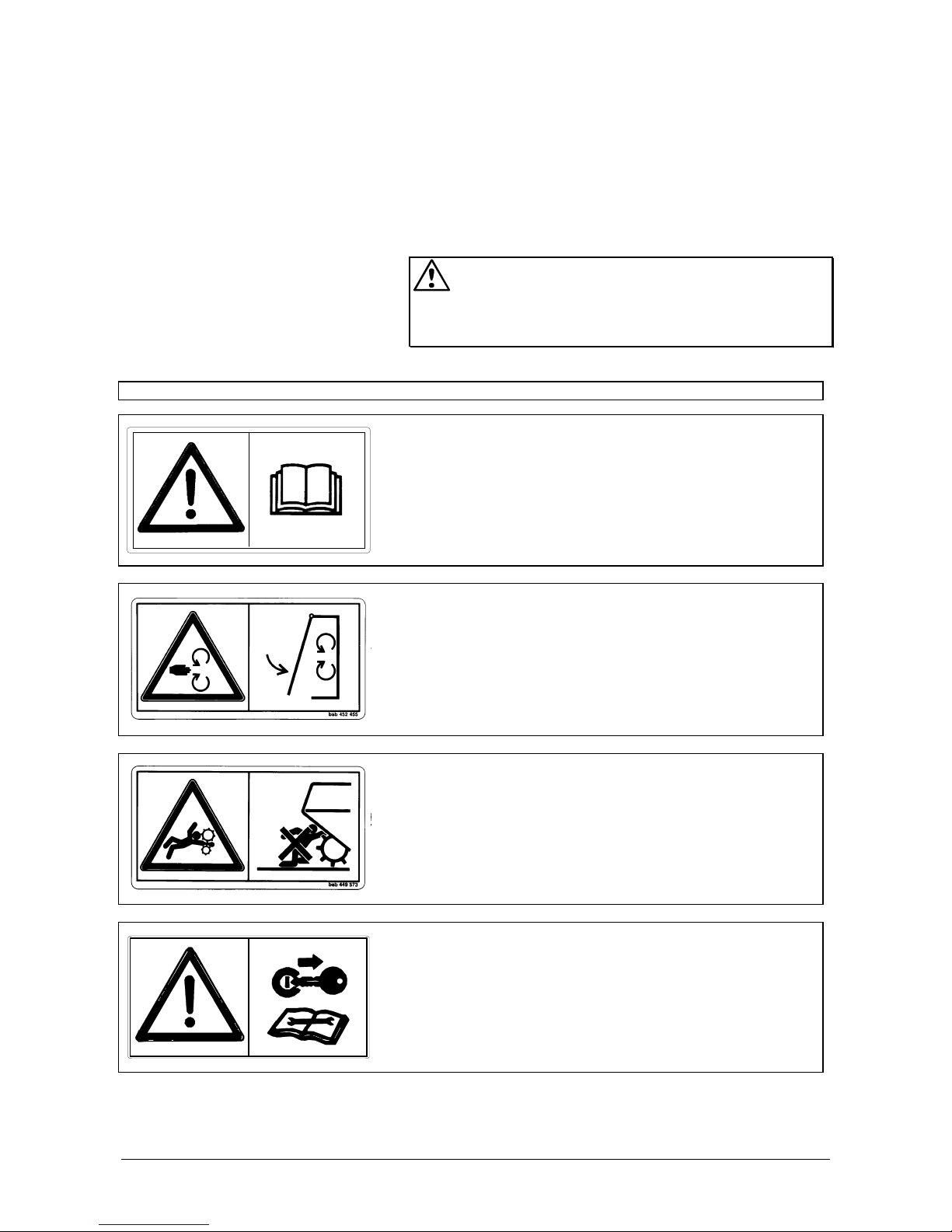

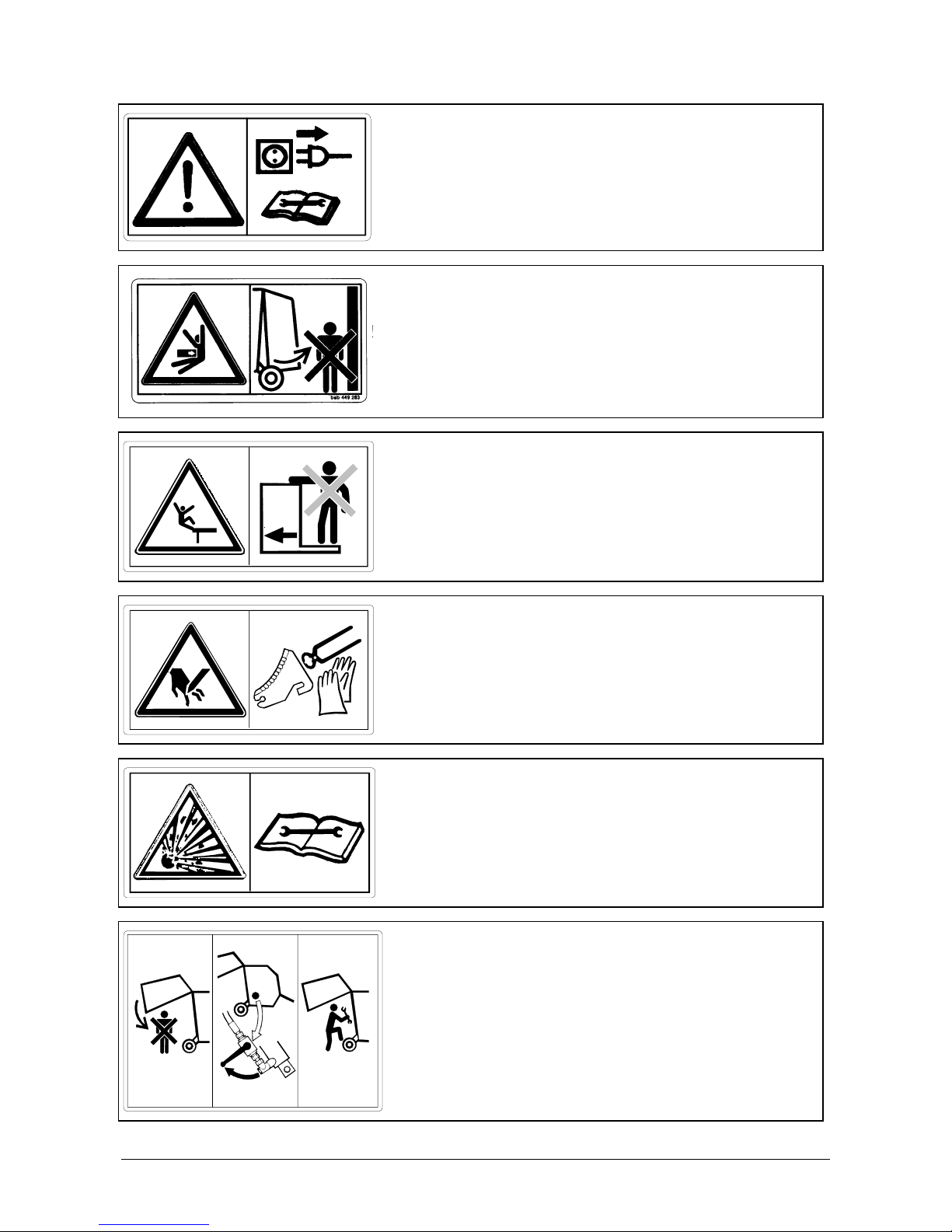

2. Your Safety

• All the protective devices such as the safety covers, rubber aprons or safety brackets are provided for

your safety! Never operate the baler with defective safety devices or if the safety devices have been

removed!

• Always keep components which are relevant to safety in a suitable condition. All guards must be fitted and

closed before putting the baler into operation!

• Never carry out adjustments, repairs or maintenance and service work on the baler while it is running.

• Always first stop the power take off (pto) shaft, detach the universal drive shaft from the pto shaft stub and

disconnect the electrical connection between the tractor and the baler prior to working on any of the

baler’s moving parts.

• Never try to remove hay, straw or other harvested crop from the baler while it is running. Always first stop

the pto shaft, and switch off the tractor engine.

• While work is in progress, only the driver should be on the tractor. Passengers are not allowed on the

baler!

• Do not climb on the drawbar or other parts of the baler when it is in operation. Also, keep your distance

from the pick-up unit. Do not reach into the working area of the transport units.

• Before threading in the binding material, switch off the baler drive and tractor engine and remove the

ignition key

• All protective guards must be fitted to the baler and must be in sound condition. Before opening the

guards, stop the pto shaft and the tractor engine, remove the ignition key and wait until the baler has

stopped.

• Before detaching the baler from the tractor, secure it with the aid of the chocks to prevent it from rolling

away. Carry the chocks with the baler when the baler is transported or used.

• Upon opening the tailgate, maintain at least 2 metres safety distance from the high voltage cables.

• All maintenance and repair work beyond that described in the descriptions in these operating instructions

must always be carried out by authorised persons. Wear parts of the brake system must always be

replaced on both sides.

• Secure the baler from tipping backwards before detaching the complete pick up unit.

Warning! The baler is inherently dangerous even if all the points listed above are followed exactly. Therefore

always take care when working with the baler to avoid endangering yourself or other people!

2.1. Noise level of tractors and machines

EU Guideline 86-188 - EEC concerning noise at the workplace instructs employers and employees to

measure and control the noise level at the workplace. The noise level during normal field work is subject to

various fluctuations which depend on the noise level of the tractor, and also on the conditions under which the

baler is being used.

The noise level generated by WELGER balers, measured at the driver's head height with the tractor window

open, is less than 70 dB(A) under normal working conditions. The combined noise level generated by the

baler and tractor primarily depends on the level of tractor noise (radios are an additional source of noise). We

recommend that the tractor be driven with the cabin windows closed.