LENCO L-78 User manual

Other LENCO Turntable manuals

LENCO

LENCO L-3867 USB User manual

LENCO

LENCO L-85 User manual

LENCO

LENCO 8711902044598 User manual

LENCO

LENCO L-90 User manual

LENCO

LENCO LS-301 User manual

LENCO

LENCO LS-300(V2) User manual

LENCO

LENCO LS-10WD User manual

LENCO

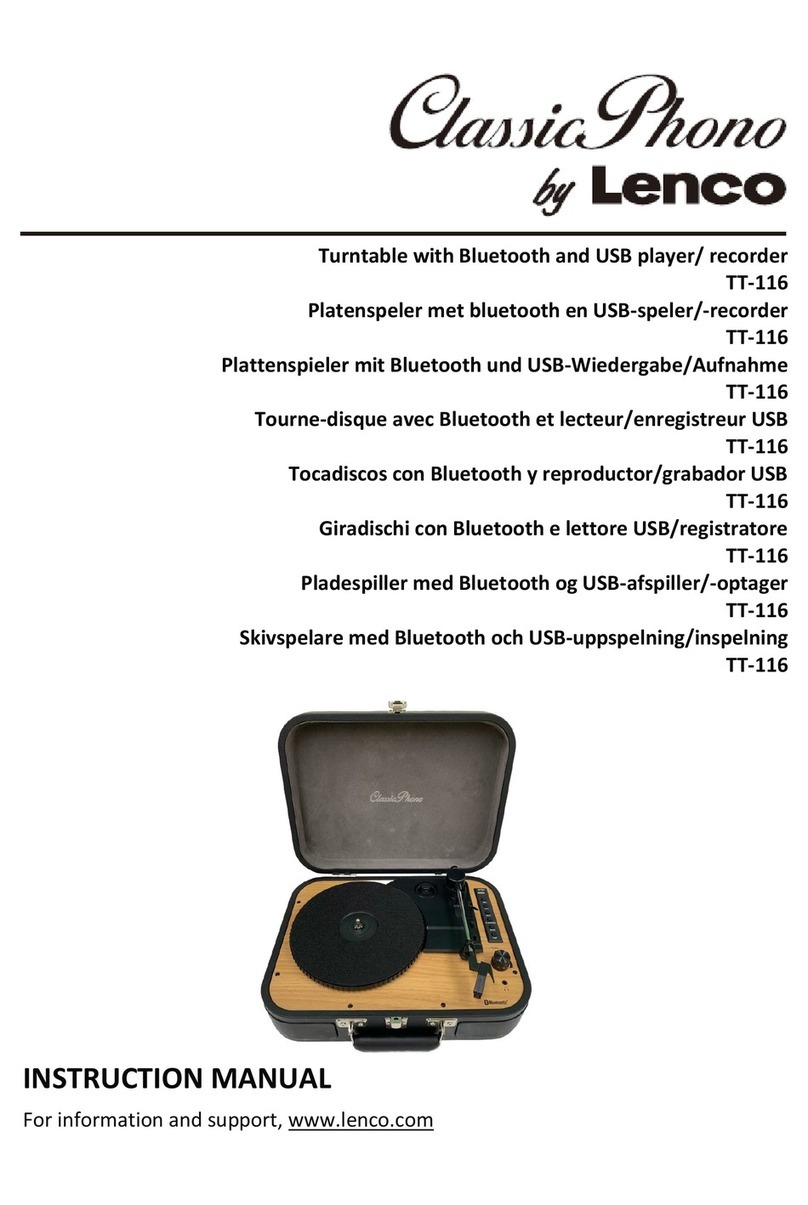

LENCO Classic Phono User manual

LENCO

LENCO LS-50TQ User manual

LENCO

LENCO ClassicPhono WS-501 User manual

LENCO

LENCO L-3806 User manual

LENCO

LENCO L-69 User manual

LENCO

LENCO LBT-188 (V2) User manual

LENCO

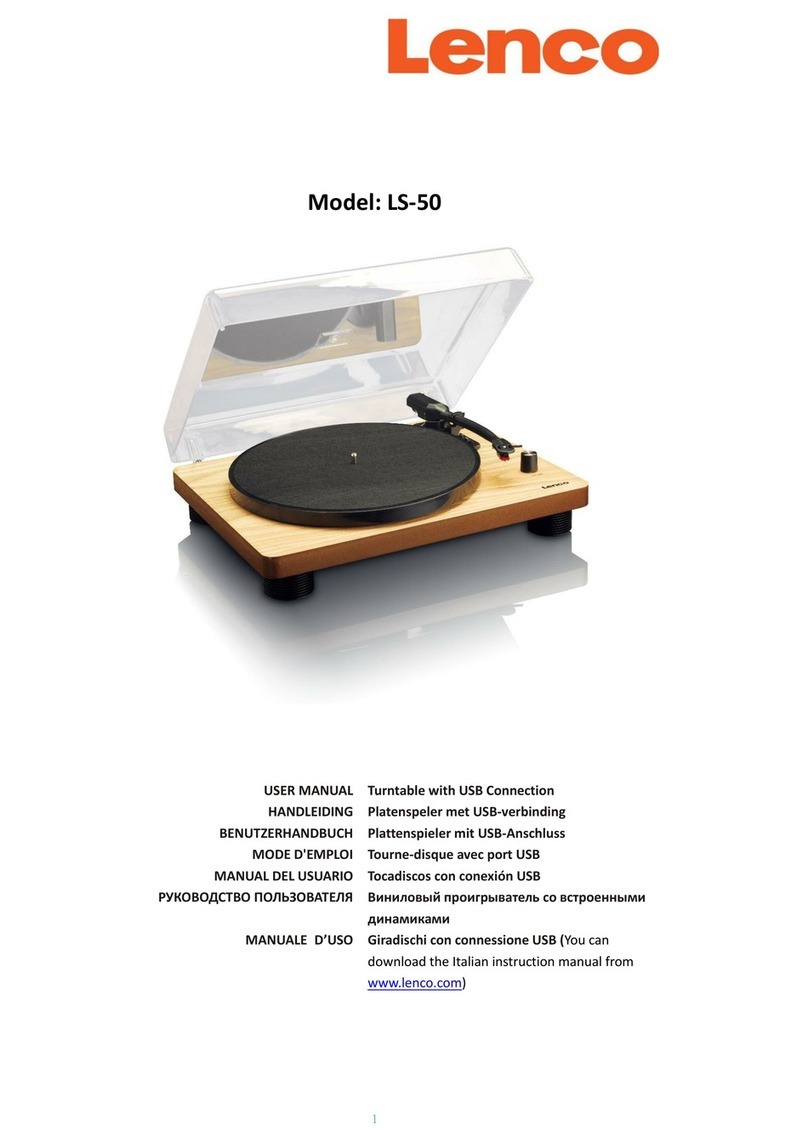

LENCO LS-50 User manual

LENCO

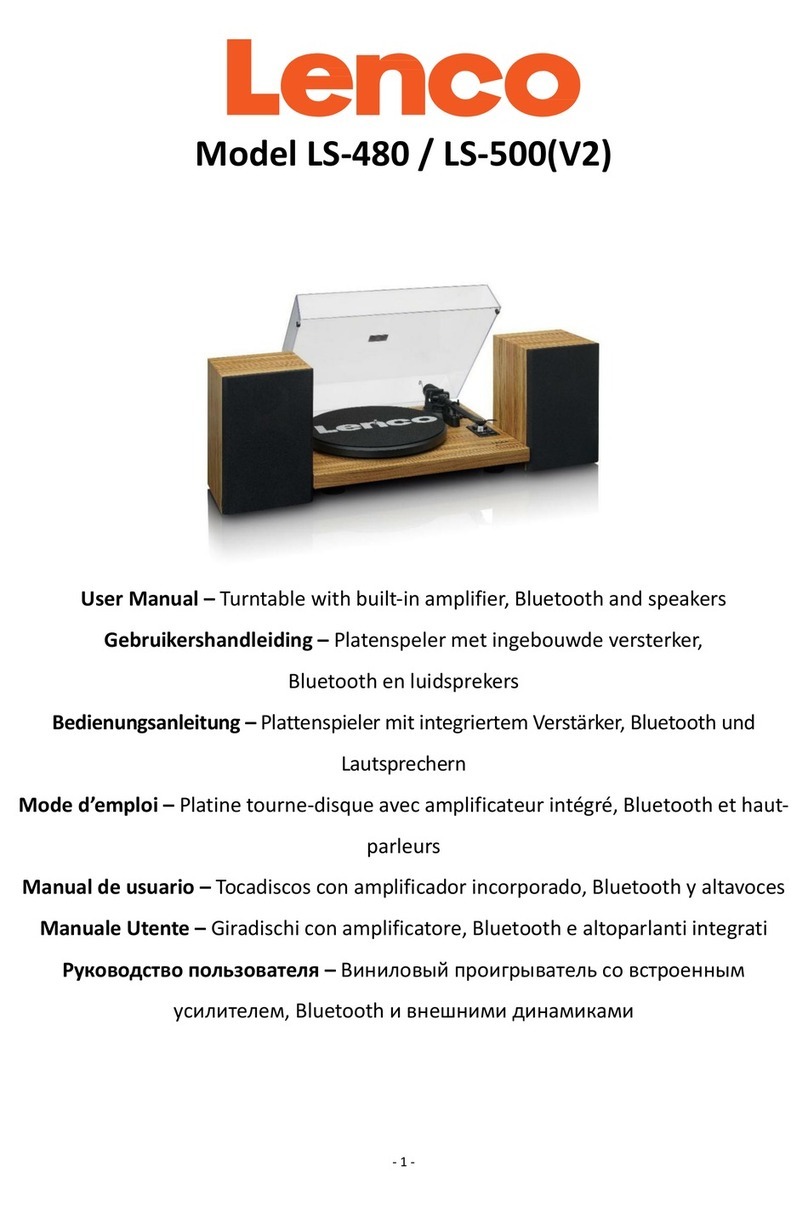

LENCO LS-480 User manual

LENCO

LENCO HP-H005 User manual

LENCO

LENCO LS-300 User manual

LENCO

LENCO LS-5000K User manual

LENCO

LENCO Classic Phono TT-34 User manual

LENCO

LENCO Classic Phono TT-41 User manual