Output Control Module LNL-1200 Series 3 Quick Reference

© 2020 Carrier. All Rights Reserved. LenelS2 is a part of Carrier. 3 QR50L-1032E — revision 3.004

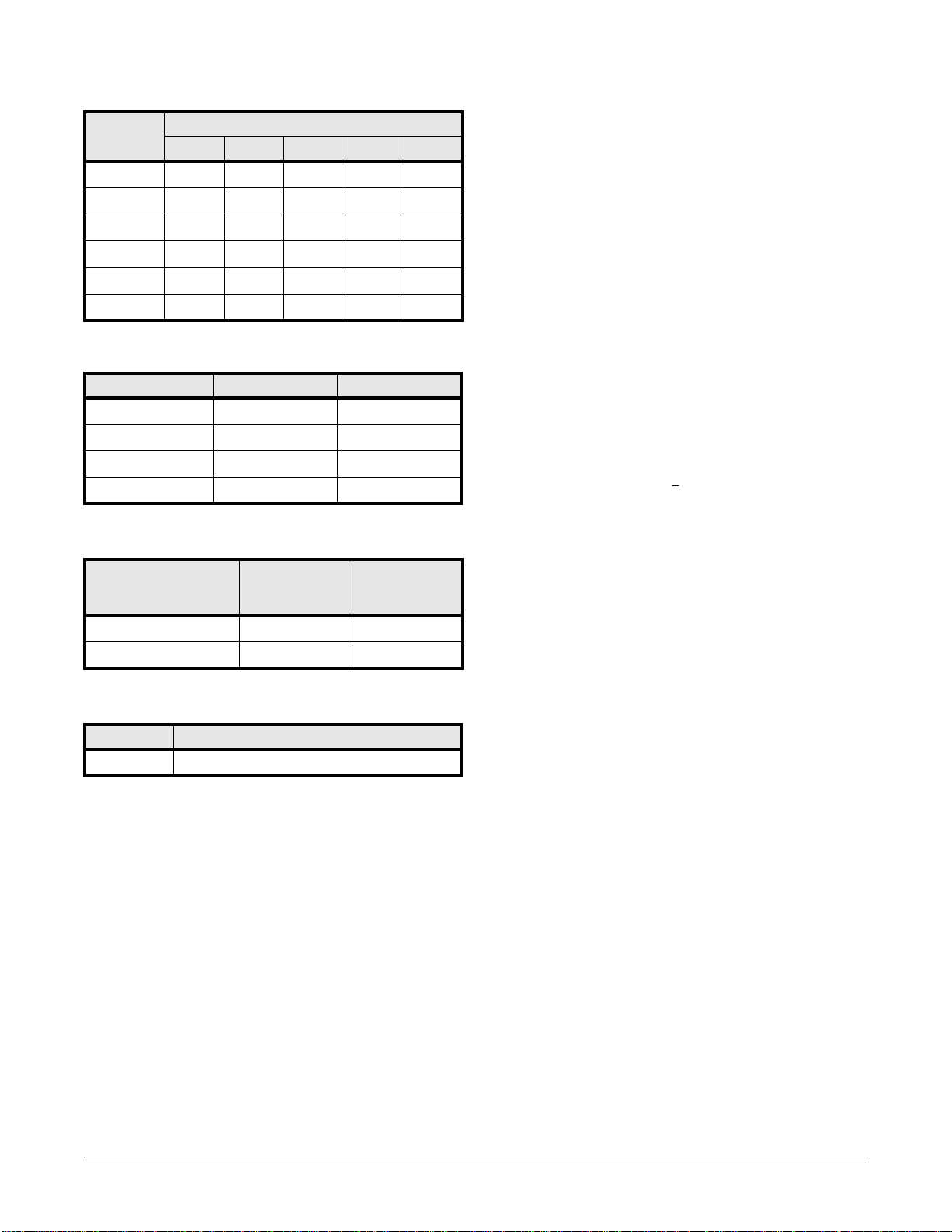

Communication Baud Rate

Bus Encryption

Jumpers

All other jumpers are factory use, only.

Status LEDs

Power-up:All LEDs OFF.

Initialization: Once power is applied, initialization of the module begins.

When initialization is completed, LEDs A. B, CT, and BA are briefly

sequenced ON then OFF.

Run time: After the above sequence, the LEDs have the following

meanings:

A LED: Heartbeat and On-Line Status:

• Off-line: 1 second rate, 20% ON

• On-line:

- Non-encrypted communication: 1 second rate, 80% ON

- Encrypted communication: 0.1 sec ON, 0.1 sec OFF, 0.1 sec

ON, 0.1 sec OFF, 0.1 sec ON, 0.1 sec OFF, 0.1 sec ON, 0.3 sec

OFF

A LED: Error Indication:

Waiting for application firmware to be downloaded: 0.1 sec ON, 0.1 sec

OFF.

B LED: Serial I/O Communication Port Status:

Indicates communication activity on the serial I/O communication port:

CT: Cabinet Tamper

BA: Power Fault

LED 1 through 16: Illuminate when output relay OUT 1 (K1), OUT 2 (K2)

is energized and so on.

Specifications

The LNL-1200 is for use in low voltage, class 2 circuit, only. These

specifications are subject to change without notice.

• Primary power: 12 to 24 VDC + 10%, 1100 mA maximum

• Relay contacts: 16 Form-C:

- Normally Open (NO) contact: 5 A @ 30 VDC resistive

- Normally Closed (NC) contact: 3 A @ 30 VDC resistive

• Inputs: 2 unsupervised, dedicated for cabinet tamper and UPS fault

monitoring

• Communication: RS-485, 2-wire: 9600, 19200, 38400, or 115200 bps

• Cable requirements:

- Power: 1 twisted pair, 18AWG

- RS-485: 24 AWG, 120 ohm impedance, twisted pair with drain

wire and shield, 4000 feet (1219 m) maximum

- Inputs:1 twisted pair, 30 ohms maximum

- Outputs: as required for the load

• Mechanical:

- Dimension: 6 x 8 x 1 in. (152 x 203 x 25.4 mm)

- Weight: 14 oz. (400 g) nominal

• Environmental:

- Temperature: -55 to 85° C storage, 0 to +70°C operating

- Humidity: 5 to 95% RHNC

UL 294, 7th edition Performance Levels:

Note: Outputs are Power limited/class 2 when powered by external

power limited/class 2 power supply model LNL-AL400ULX or

LNL-AL600ULX-4CB6.

26 ON ON off ON off

27 ON ON off ON ON

28 ON ON ON off off

29 ON ON ON off ON

30 ON ON ON ON off

31 ON ON ON ON ON

Baud rate DIP switch 6: DIP switch 7:

38,400 bps ON ON

19,200 bps off ON

9600 bps ON off

115,200 bps off off

Bus communications DIP switch 8:

(OnGuard 2009

or later)

DIP switch 8:

(prior to

OnGuard 2009)

Encryption is not required off Normal operation

Encryption is required ON Not allowed

Jumper Description

J1 RS-485 termination; install in first and last units, only

Address DIP switch

5: 4: 3: 2: 1:

Feature Level

Standby Power I

Endurance IV

Line Security I

Destructive Attack I