Lennox @DNOVA 2mAC ADVANCED CONTROLLER User manual

Other Lennox Controllers manuals

Lennox

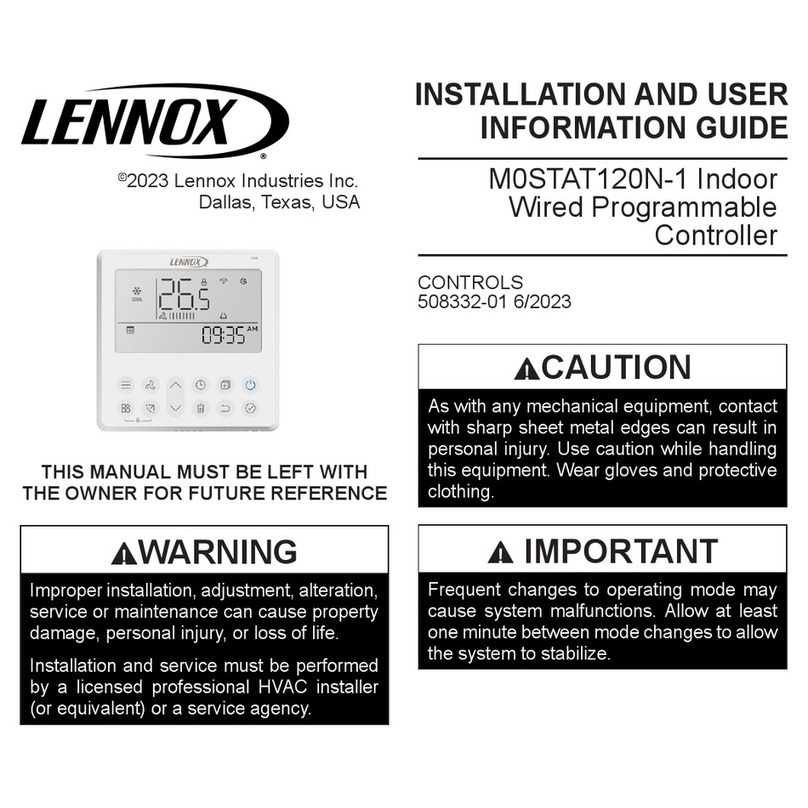

Lennox M0STAT120N-1 User manual

Lennox

Lennox VRF VEWCL1B User manual

Lennox

Lennox E210 Instruction manual

Lennox

Lennox V0STAT52 User manual

Lennox

Lennox HYDRON Series Instruction manual

Lennox

Lennox M0STAT64Q-2 Installation instructions

Lennox

Lennox Core Unit Controller User manual

Lennox

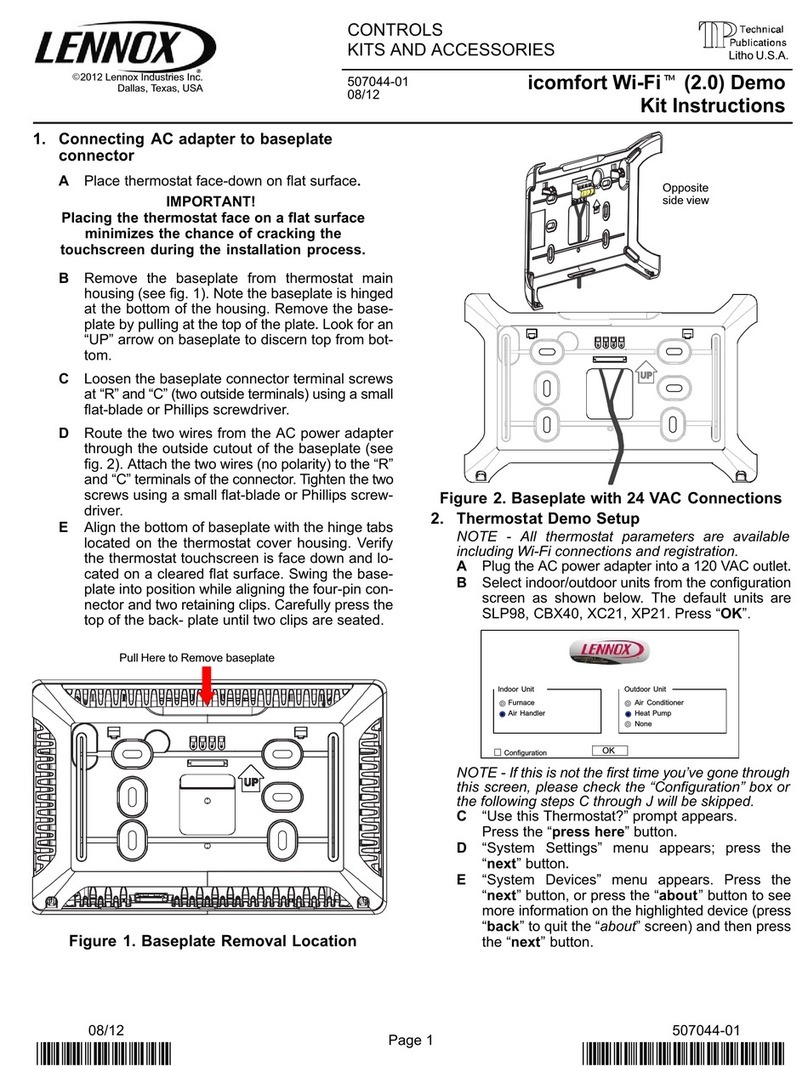

Lennox icomfort Wi-Fi (2.0) Demo User manual

Lennox

Lennox F1943L-3P User manual

Lennox

Lennox CLIMATIC 200 User manual

Lennox

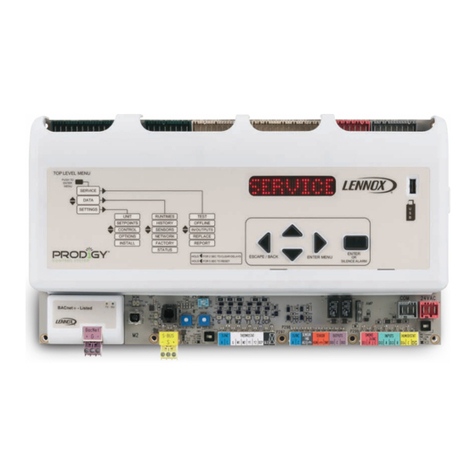

Lennox Prodigy User manual

Lennox

Lennox @DNOVA pCO1 User manual

Lennox

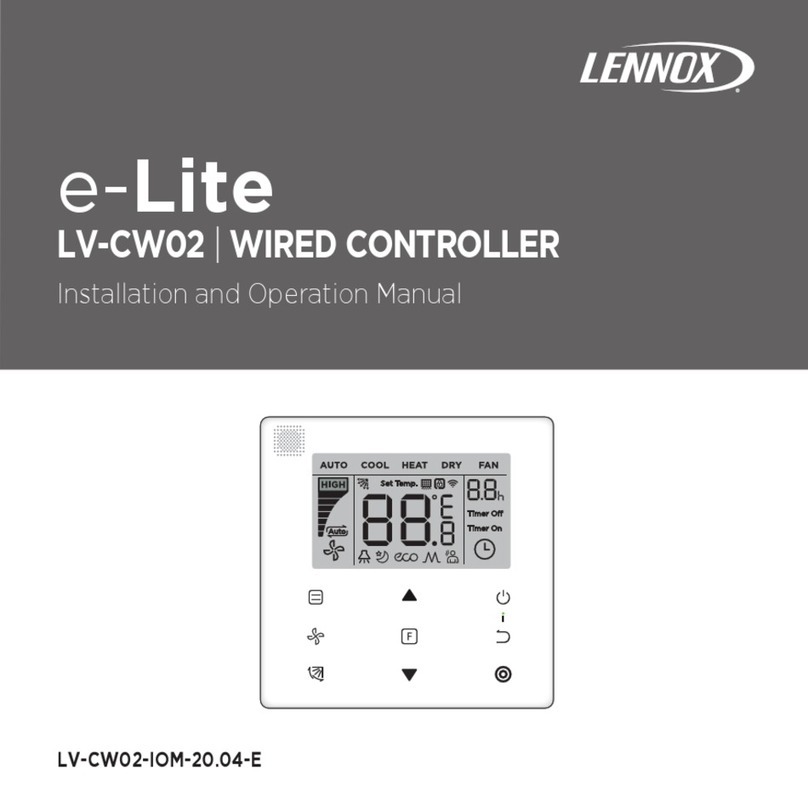

Lennox e-Lite LV-CW02 User manual

Lennox

Lennox V0STAT51P-2 User manual

Lennox

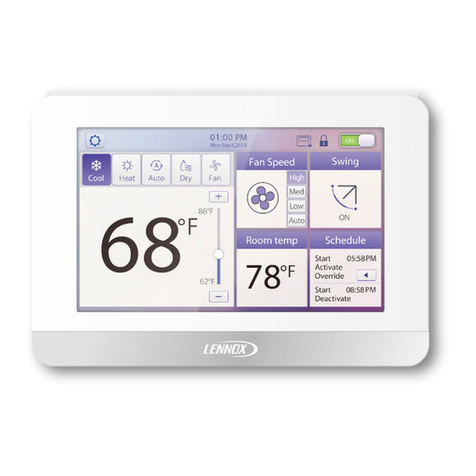

Lennox VRF VEWCL1E User manual

Lennox

Lennox 22U50 User manual

Lennox

Lennox HYDROCONTROL User manual

Lennox

Lennox M0STAT60Q-1 User manual

Lennox

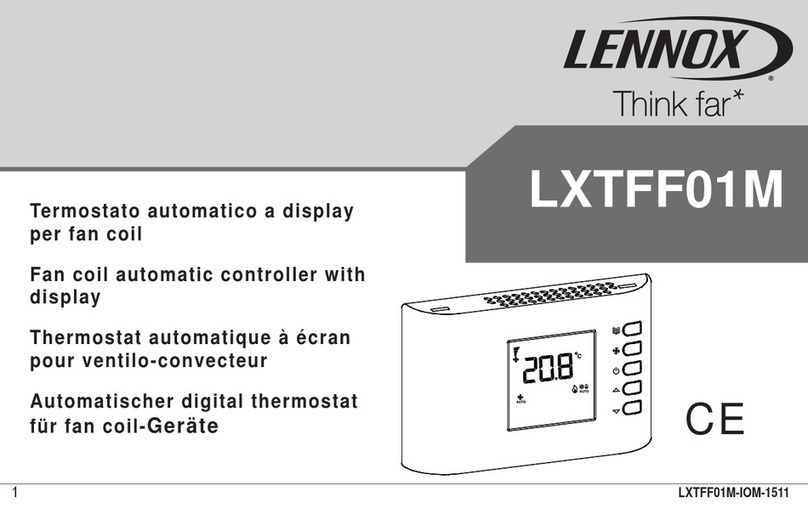

Lennox LXTFF01M User manual

Lennox

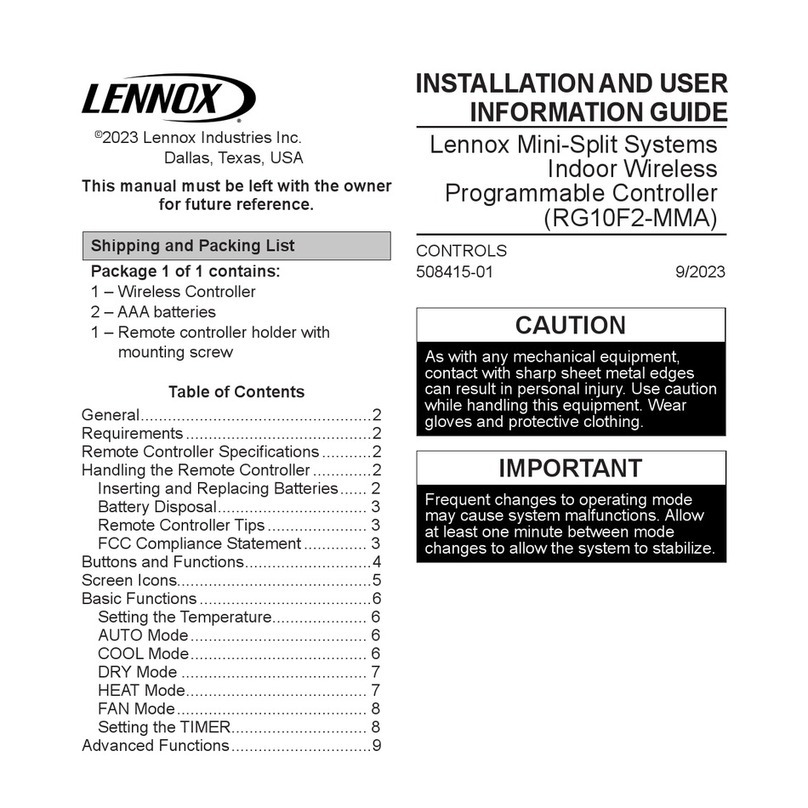

Lennox RG10F2-MMA User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions