Page 6

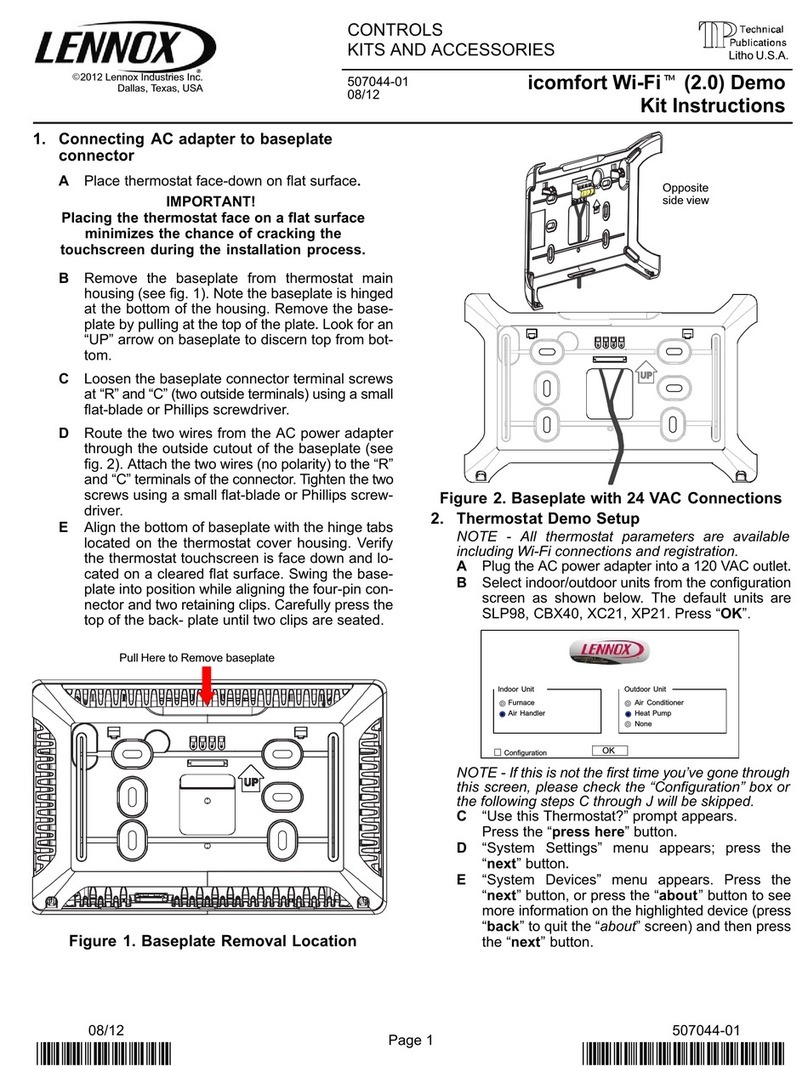

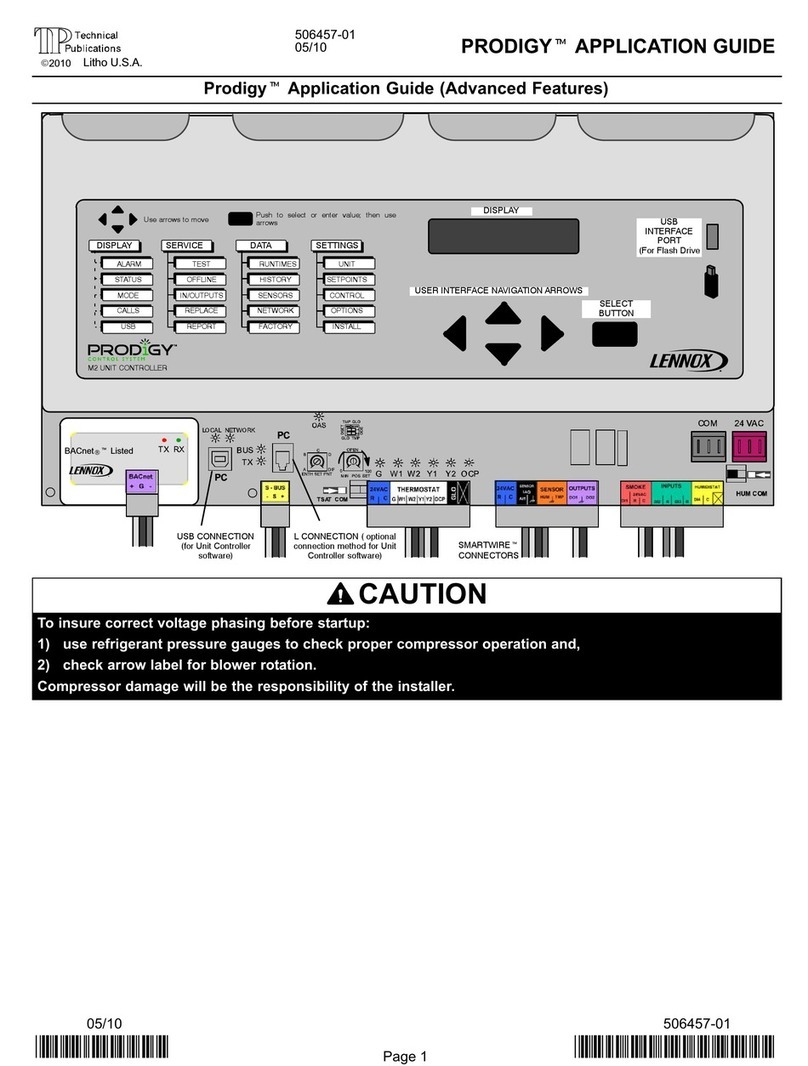

Menu Interface DISPLAY

The display shows operating mode if in normal operation.

Alarm, status, calls and plugging in the USB will interrupt

the display. Alarm messages will stay displayed until cor-

rected or silenced using the local menu.

DISPLAY

ALARM

STATUS

MODE

CALLS

USB

Dashed line for automatic

displayed messages

ALARM Example ˘ MODE message

COOLING" is displaying when a smoke

alarm occurs; then ALARM:(XX) SMOKE

A17" displays until cleared. You must

clear all alarms and status to see normal

MODE message. Strike 3 alarms will say

ALARM(XX):STRIKE 3 COMP1 HIGH

PRESS S4" after the alarm message.

USB ˘ normal MODE message is dis-

played when USB is plugged in; message

examples:

WRITING USB"

WRITING ALARM/STATUS LOG"

USB COMPLETE"

Normal Mode Messages

The format of the message is mode and setpoint (see table

3).

Table 3. Possible MODE messages

BLOWER Blower only

COOLING Cool demand present; unit is cooling

FREE COOLING No compressor cooling

FRESH AIR COOL Cool ventilation air to neutral value

FRESH AIR HEAT Heat ventilation air to neutral value

HEATING Heat demand present; unit is heating

HVAC OFF No heat, cool, ventilation allowed

IDLE Demand satisfied; blower off

MORNING WARMUP Outdoor air damper closed

M2 FAILED TO RESPOND Display is missing messages from

M2

PRE−COOL No compressor allowed when free

cooling

PRE−INSTALL Must follow installation menus

REHEAT Unit is dehumidifying

SMOKE Smoke input detected

TEST Network has unit in test mode

(blank screen) Bootloader mode

Unit Operation

This section describes the display and control buttons,

how to configure the unit, and how to read stored configu-

ration data, status, and alarms.

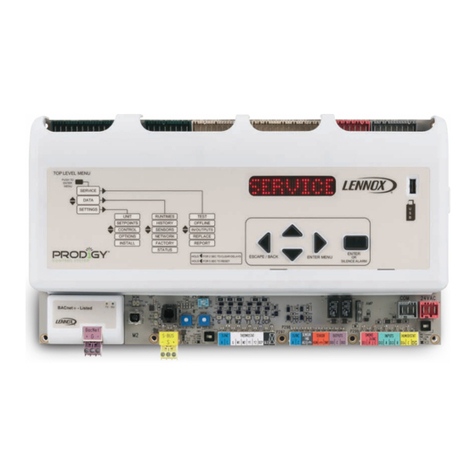

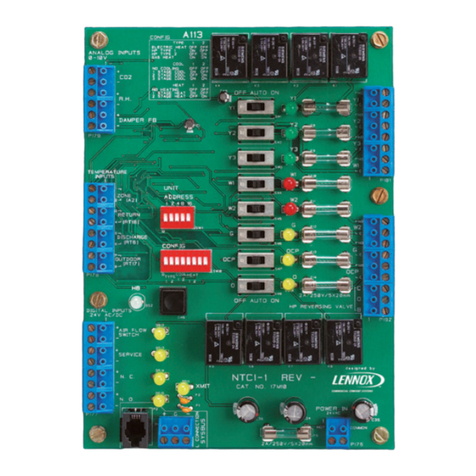

The M2 unit controller is an input and output junction

point. If in the thermostat mode, thermostat inputs at

P297 result in an output to unit components (see table 11

on Page 30). If the heartbeat LED is not flashing, see

table 1 (Page 3) for heartbeat operation. If the display

shows an alarm, refer to table 10 (Page 22) for more in-

formation. If the thermostat input indicating lights are not

responding appropriately, check the thermostat or a

DDC control acting as thermostat inputs into P297.

Basic cooling and heating functions may be energized to

test major unit components by using the M2 unit controller

testing function or by using jumper wires on the Field Wir-

ing Termination plug P297.

To access the other three columns, first press and then

use to scroll between SERVICE, DATA, AND SET-

TINGS. Next, press to open the SERVICE (or DATA or

SETTINGS) menu. Use until desired item is dis-

played.

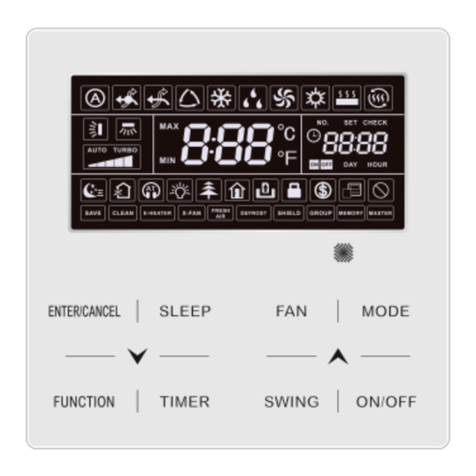

Alarms

Figure 3 shows a typical alarm and how the message will

scroll.

ALARM(xx): SMOKE DETECTED.

DISPLAY

WINDOW

LEFT SCROLLING

MESSAGE

(To SILENCE an alarm,

press any of these buttons.)

Figure 3. Alarm Code Readout Example

SILENCE − to silence an alarm, press any of the control

buttons while the alarm is displayed.

USB Service Verification

When the Lennox USB drive is plugged in during normal

MODE, a message will be displayed to indicate data is be-

ing written to the drive. When finished, the message USB

COMPLETE" will be displayed.

From the USB you may get the last report from the M2 unit

controller and view it using any PC text program.

Multiple units may use the same USB drive. The filename

of the service reports will be based on the unit’s serial num-

ber; for example 5608J5875.txt.