2

WARNING

Young children should be

carefully supervised when they

are in the same room as the

appliance. Toddlers, young

children and others may be

susceptible to accidental contact

burns. A physical barrier is

recommended if there are at

risk individuals in the house.

To restrict access to a fireplace

or stove, install an adjustable

safety gate to keep toddlers,

young children and other at risk

individuals out of the room and

away from hot surfaces.

AVERTISSEMENT

Les jeunes enfants devraient

être surveillés étroitement

lorsqu’ils se trouvent dans la

même pièce que l’appareil.

Les tout petits, les jeunes

enfants ou les adultes

peuvent subir des brûlures

s’ils viennent en contact

avec la surface chaude. Il

est recommandé d’installer

une barrière physique si des

personnes à risques habitent

la maison. Pour empêcher

l’accès à un foyer ou à un

poêle, installez une barrière

de sécurité; cette mesure

empêchera les tout petits,

les jeunes enfants et toute

autre personne à risque

d’avoir accès à la pièce et aux

surfaces chaudes.

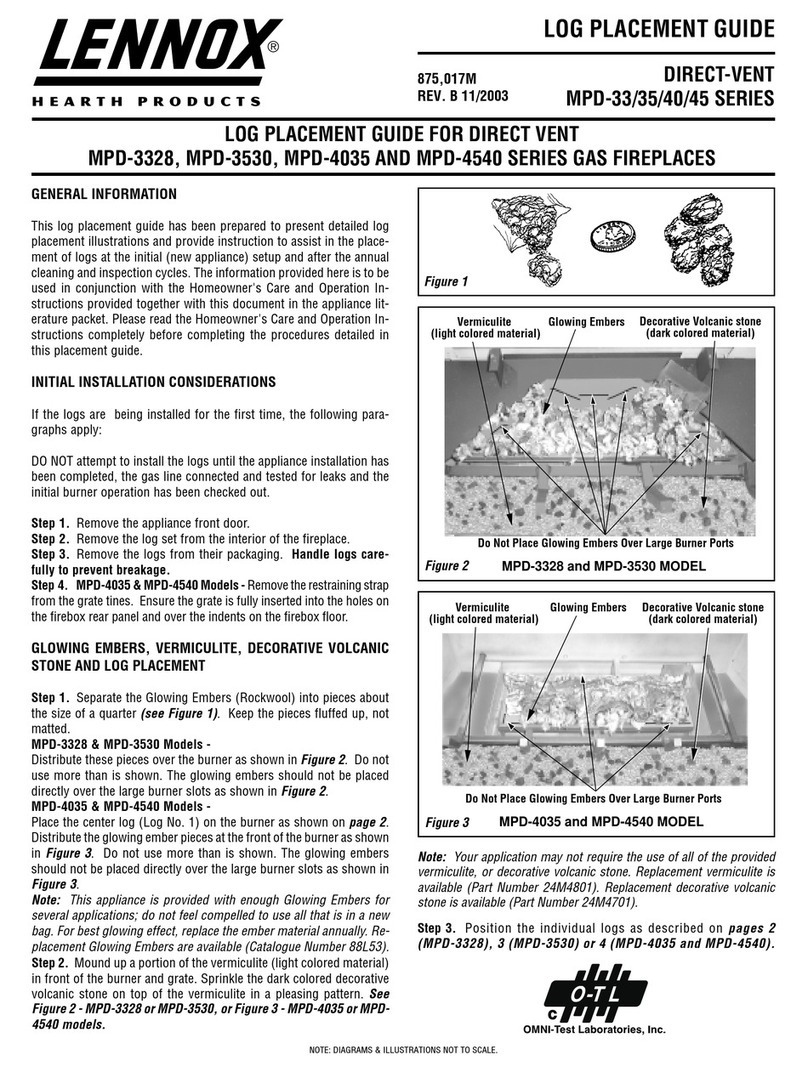

GENERAL INFORMATION

LENNOX HEARTH PRODUCTS • MONTEBELLO® DLX POWER VENT DV GAS FIREPLACES (MDLX40/45IN-PV) • INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Packaging .........................................Page 2

Introduction ......................................Page 2

General Information ..........................Page 2

Massachusetts Requirements...........Page 4

Cold Climate Insulation .....................Page 5

Manufactured Home Requirements ..Page 5

Location............................................Page 5

Vent Termination Clearances ............Page 6

Minimum Clearances to Combustibles Page 8

Pre-Installation Steps........................Page 9

Typical Installation Sequence ...........Page 9

Detailed Installation Steps.................Page 9

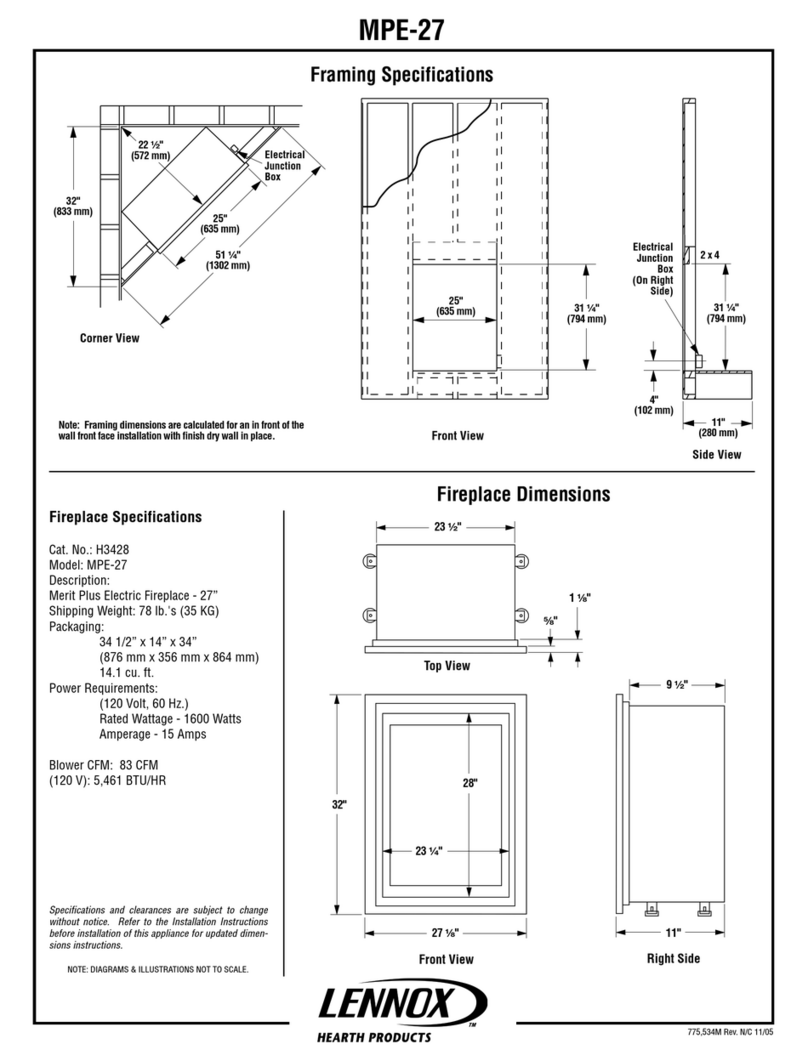

Step 1. Framing...............................Page 9

Fireplace and Framing Specifications Page 10

Step 2. Routing Gas Line ................Page 11

Proper Sizing of Gas Line..................Page 11

Step 3. Install the Vent System .......Page 12

General Vent Information..................Page 12

Power Vent Components...................Page 12

Vent Section Length Chart ................Page 13

Offset Installation..............................Page 13

Horizontal Termination System .........Page 16

Installing Power Vent Termination ....Page 16

Step 4. Field Wiring.........................Page 18

Step 5. Removing Glass Door

Frame Assembly ...............................Page 20

Step 6. Connecting Gas Line ...........Page 21

Step 7 Install Firebox Liner ............Page 21

Step 8. Verifying Appliance

Operation ..........................................Page 21

Step 9. Installing Logs ...................Page 22

Step 10. Install/Remove Glass

Door Assembly .................................Page 24

Step 11. Burner Adjustments............Page 24

Finishing Requirements ....................Page 26

Step 12. Attaching Safety-in-

Operation Warnings ...................

Page 27

Installation Accessories ....................Page 28

PACKAGING

The assembled vented gas fireplace is packaged with:

BOX 1—Fireplace:

• Literature Kit (plastic bag shipped

inside rebox),

• Bags of Glowing Embers, Platinum Embers,

and Volcanic Stone

•Pull Screen

• Door Modesty Shield

• Adaptor with Probe Assembly

• (1) Remote Control Kit and Receiver Kit

BOX 2—Power Vent Components:

• (1) Power Vent Termination

• (1) Termination Adaptor

• (1) Horizontal Firestop Assembly

• (1) Vacuum Hose

• (1) 11/32 in. Hose Clamp

• (1) Strain Relief

• (1) Bushing

• (4) Insulated 1/4 in. Male Terminals

• (2) #10 Ring Terminals

REQUIRED ACCESSORIES

The following accessories are required:

• One of the following Firebox Liner Kits:

a. Ceramic Liner Kit—Buff Rustic

b. Ceramic Liner Kit—Red Rustic

c. Porcelain Liner Kit—Black

d. Ceramic Liner Kit—Red Herringbone

e. Ceramic Liner Kit—Buff Herringbone

NOTE: Porcelain kits include side and back

panels. Optional for use with log sets.

Required when using the contemporary

burner/floor kit.

• One of the following Floor Options:

a. Oak Log Set (For use with fireplace as

shipped from factory only. Not for use with

contemporary burner/floor kit.)

b. Contemporary Burner/Floor Kit

Contemporary Burner/Floor Kit requires

one of the following Media Kits:

i. Crushed Glass—Reective Black

ii. Crushed Glass—Platinum

iii. Crushed Glass—Reective Blue

iv. Crushed Glass—Goldfinger

v. Crushed Glass—Copper

NOTE: The Contemporary Burner/Floor Kit

installation instructions are provided

with the kit, and are not detailed in this

manual.

INTRODUCTION

These Electronic appliances are designed to

operate on natural gas and have an electronic

intermittent pilot ignition system. External

120 Volt AC electrical power is required to

operate these units.

These vented gas fireplaces are sealed

combustion gas replaces designed for

residential, manufactured home, and

commercial applications.

Use Only These Approved Vent Components

These replaces are designed, tested and

listed for operation and installation with, the

following (4 1/2 in. inner and 7 1/2 in. outer)

vent components only:

• Secure Vent®Direct-vent system

components manufactured by Security

Chimneys International.

These approved vent system components

are labeled for identication. Do NOT use any

other manufacturer’s vent components with

these appliances.

Children and adults should be alerted to the

hazards of high surface temperature and should

stay away to avoid burns or clothing ignition.

Les enfants et les adultes devraient être

infor-més des dangers que posent les

températures de surface élevées et se

tenir à distance afin d’éviter des brûlures

ou que leurs vêtements ne s’enflamment.

DO NOT ATTEMPT TO ALTER OR MODIFY

THE CONSTRUCTION OF THE APPLIANCE

OR ITS COMPONENTS. ANY MODIFICATION

OR ALTERATION MAY VOID THE

WARRANTY, CERTIFICATION AND LISTINGS

OF THIS UNIT.