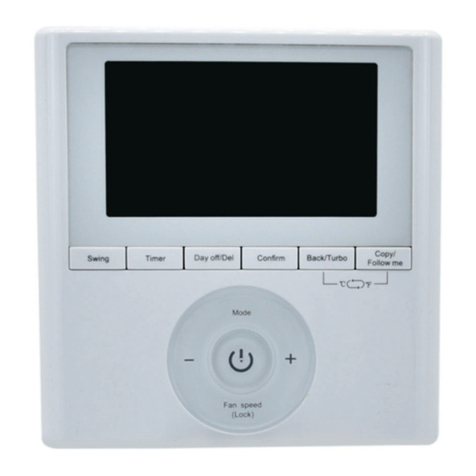

Functions

The controller acquires the room temperature with its integrated sensor or external

room temperature sensor (QAA32) or external return air temperature sensor (QAH11.1)

– if used – and maintains the setpoint by delivering control commands to the 2-point-

valve. The switching differential can be 1 or 4 K in heating mode and 0.5 or 2 K in cool-

ing mode.

The fan is switched to the selected speed via control output Q1, Q2 or Q3.

When the function “Temperature-dependent fan control“ is activated (can be selected

with DIP switch no.1), the fan is switched on / off depending on the temperature, that is,

together with the valve.

It is switched off by

• leaving the heating or cooling sequence, provided the function “Temperature-

dependent fan control“ is activated, or

• manually changing to standby , provided plant conditions do not call for frost

protection mode, or

• activating an external operating mode changeover switch, provided plant conditions

do not call for energy saving or frost protection mode, or

• by turning the controller’s power supply off.

To avoid overtemperatures of the electrical heater or to prevent the thermal cutout from

responding, the fan will overrun for 30 seconds when the electrical heater is switched

off. During that period of time, the fan LED flashes.

In the event of failure, the RCC20 cannot protect the electric heater against overtem-

peratures. For this reason, the electric heater must be equipped with a separate safety

device (thermal cutout).

The heating or cooling valve receives the OPEN command via control output Y11 when

1. the measured room temperature lies by half the switching differential below the

setpoint (heating mode) or above the setpoint (cooling mode), and

2. the valve has been fully closed for more than one minute.

The heating or cooling valve receives the CLOSE command via control output Y11

when

1. the measured room temperature lies by half the switching differential above the

setpoint (heating mode) or below the setpoint (cooling mode), and

2. the valve has been fully open for more than one minute.

Note: control output Y12 delivers a control command which is inverted to the

control command at output Y11 and can be used for normally open valves

The RCC20 provides control either depending on to the measured room temperature or

depending on the fan coil unit’s return air temperature. Changeover is automatic if a

QAH11.1 cable temperature sensor is used.

The water temperature acquired by the changeover sensor (QAH11.1 + ARG86.3) is

used by the controller to switch from heating to cooling mode, or vice versa. When the

water temperature lies above 28 °C, the controller switches to heating mode, below

16 °C it switches to cooling mode. If, immediately after switching on, the water tempera-

ture lies between the 2 changeover points, the controller will start in heating mode. The

water temperature is measured at minute-intervals and the operational status updated.

Fan operation

Note

ON

Heating and cooling

mode

.

.

.

.

.

OFF

Return air tempera-

ture

Automatic

changeover