The water temperature acquired by the changeover sensor (QAH11.1 + ARG86.3) is

used by the controller to switch from heating to cooling mode, or vice versa. When the

water temperature lies above 28 °C, the controller switches to heating mode, below

16 °C it switches to cooling mode. If, immediately after switching on, the water tempera-

ture lies between the 2 changeover points, the controller will start in heating mode. The

water temperature is measured at minute-intervals and the operational status updated.

Heating mode Cooling mode Automatic changeover

1

0

SDH

Y11

W

3021D01

T [°C]

1

0

SDC

Y11

W

T [°C]

3021D02

CM

HM

M

T

W

[°C]

3021D03

16 28

CM Cooling mode TWWater temperature

HM Heating mode w Room temperature setpoint

M Operating mode Y11 Manipulated variable “Valve“

SDC Switching differential “Cooling“ T Room temperature

SDH Switching differential “Heating“

The task of the changeover sensor is to initiate the change from heating to cooling

mode even if the two-port valves are shut down for a longer period of time. To ensure

this function, the valves are opened for one minute at 2-hour intervals during off hours.

(Note: this function is not effective when using thermal actuators)

The room temperature setpoint can be limited in increments of 1 K by making use of

the minimum and maximum limitation facility. Arbitrary setpoint readjustments can thus

be prevented.

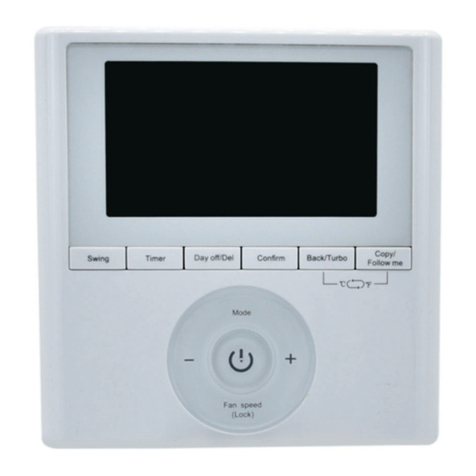

Operating modes

The following operating modes are available:

Heating or cooling mode with automatic changeover and with manually selected fan

speed III, II or I. In normal operation, the controller maintains the adjusted setpoint.

The frost protection function is activated only when DIP switch no.4 is set to OFF.

Frost protection mode can be activated either

• by manually switching to standby .

• by activating the external operating mode changeover switch, provided DIP switch

no.2 is set to OFF

If the room temperature falls below 8 °C, the controller will automatically switch to frost

protection mode. In that case, the heating valve opens and the fan operates at the se-

lected speed. If the operating mode selector is in position standby , the fan will oper-

ate at speed I. The room temperature is maintained at a setpoint of 8 °C and the set-

point adjusted by the user will be ignored.

If frost protection mode is locked (DIP switch no.4 in position ON), standby is locked

also, which means that the controller will not switch to standby but to OFF:

In energy saving mode, the setpoint of heating is 16 °C and the setpoint of cooling 28

°C, independent of the position of the setpoint knob. This operating mode will be acti-

vated when input D1 for operating mode changeover is active and DIP switch no.2 is

set to ON.

Automatic

changeover

Purging function

Energy saver

Normal operation

Frost protection mode

(only with the RCC10)

Energy saving

mode