Inhalt

1Safety precautions................................................................................3

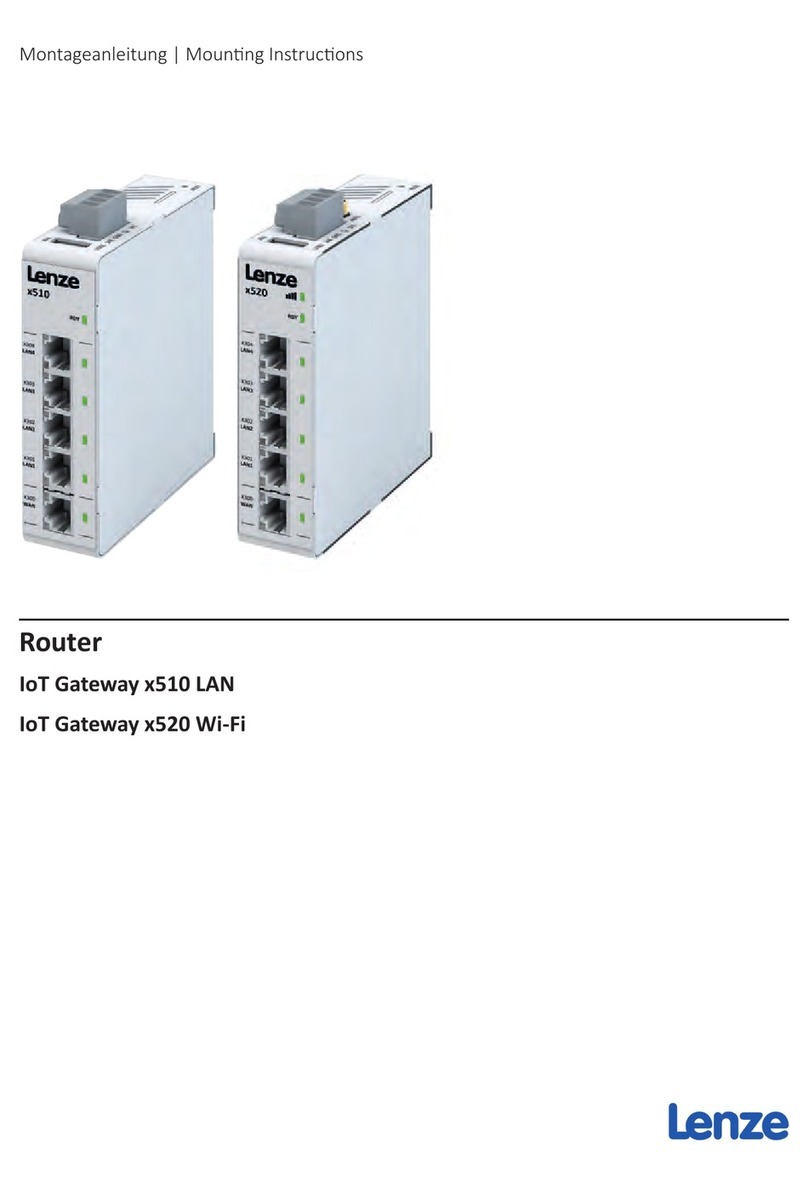

2Overview ..............................................................................................7

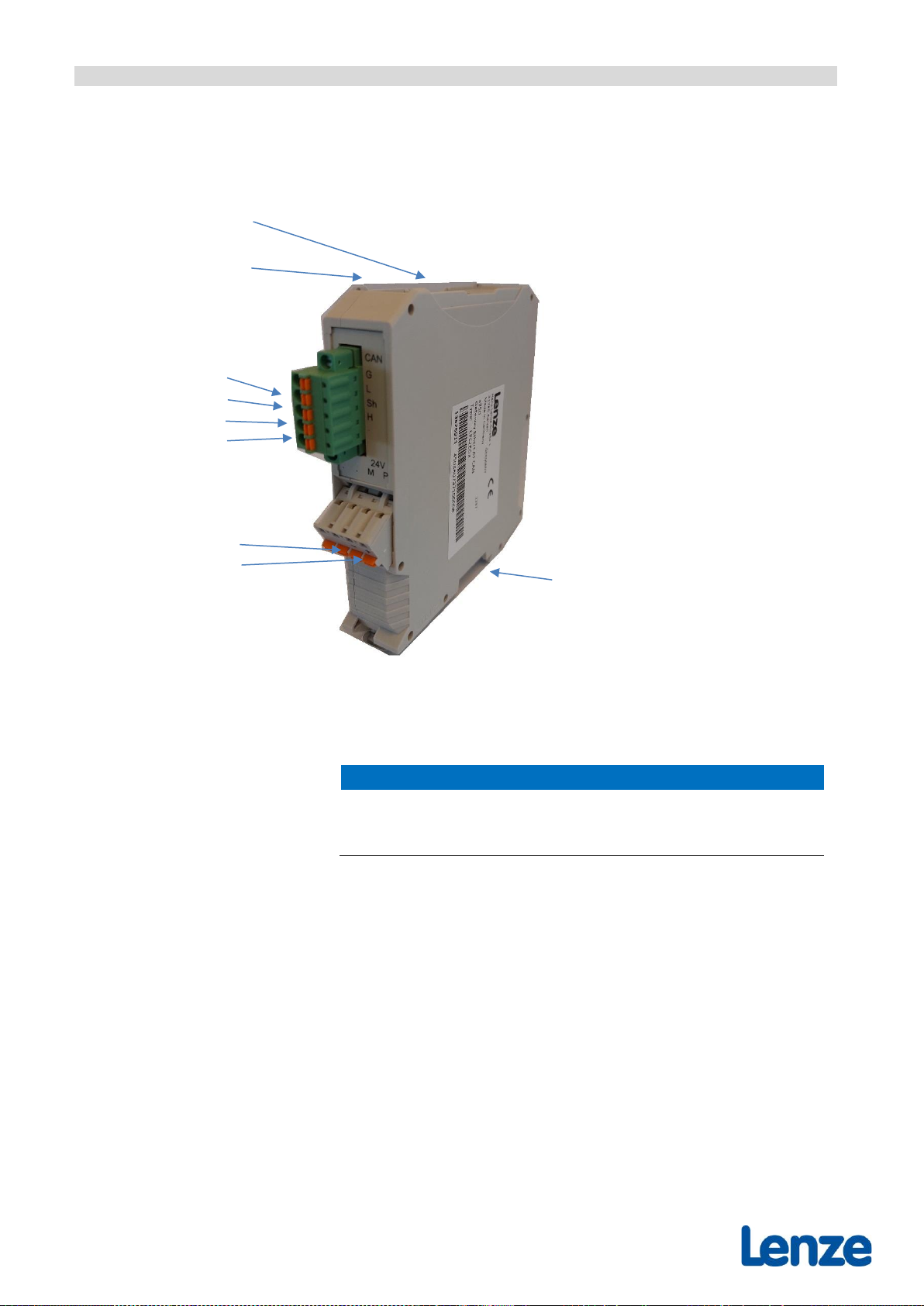

3Hardware Description...........................................................................8

3.1 Connections .........................................................................................8

3.2 LEDs.....................................................................................................9

3.2.1 LED Assignment...................................................................................9

4Hardware Installation..........................................................................11

5Configuration......................................................................................12

5.1 Application Example...........................................................................12

5.2 Configuration Sequence.....................................................................12

5.2.1 Step 1: Add Gateway .........................................................................13

5.2.2 Step 2: Add CANOpen Devices to the Project....................................13

5.2.3 Step 3: Configure the Gateway ..........................................................14

6EtherCAT Communication..................................................................16

6.1 CAN Interface.....................................................................................16

6.1.1 Object Dictionary Structure.................................................................16

6.1.2 Object Dictionary................................................................................17

6.1.3 Standard Objects (1000h...1FFFh)......................................................18

6.1.4 Manufacturer Specific Objects (2000h-5FFFh)....................................22

6.1.5 Profile Specific Objects (6000h-FFFFh)...............................................26

7Technical Data ...................................................................................37

7.1 General Technical Data......................................................................37

7.2 Microprocessor and Memory..............................................................37

7.3 CAN Interface.....................................................................................37

7.4 EtherCAT Interface.............................................................................38

7.5 Operating System and License Information........................................38

8Interfaces and Connector Assignments..............................................39

8.1 24V-Power Supply Voltage.................................................................39

8.2 CAN....................................................................................................40

8.2.1 CAN Connector ..................................................................................40

8.3 EtherCAT............................................................................................42

8.4 Conductor Connection/ Conductor Cross Sections...........................43

9Order Information...............................................................................44

10 License Terms....................................................................................45

10.1 GPL V1...............................................................................................45

10.2 GPL V2...............................................................................................46

10.3 OpenBSD License..............................................................................47

10.4 MIT Lizenz..........................................................................................47