Bulletin P-2GLR

August 2018

1360 Elmwood Avenue, Cranston, RI 02910 USA

Phone: 401.461.1200 Fax: 401.941.5310

Web Site: http://www.leonardvalve.com

AQUATROL® 4500-LR

PRESSURE BALANCING MIXING VALVE (1/2”)

INSTALLATION, ADJUSTMENT, & SERVICE

Serial No. PG2800 and higher

INSTALLATION INSTRUCTIONS

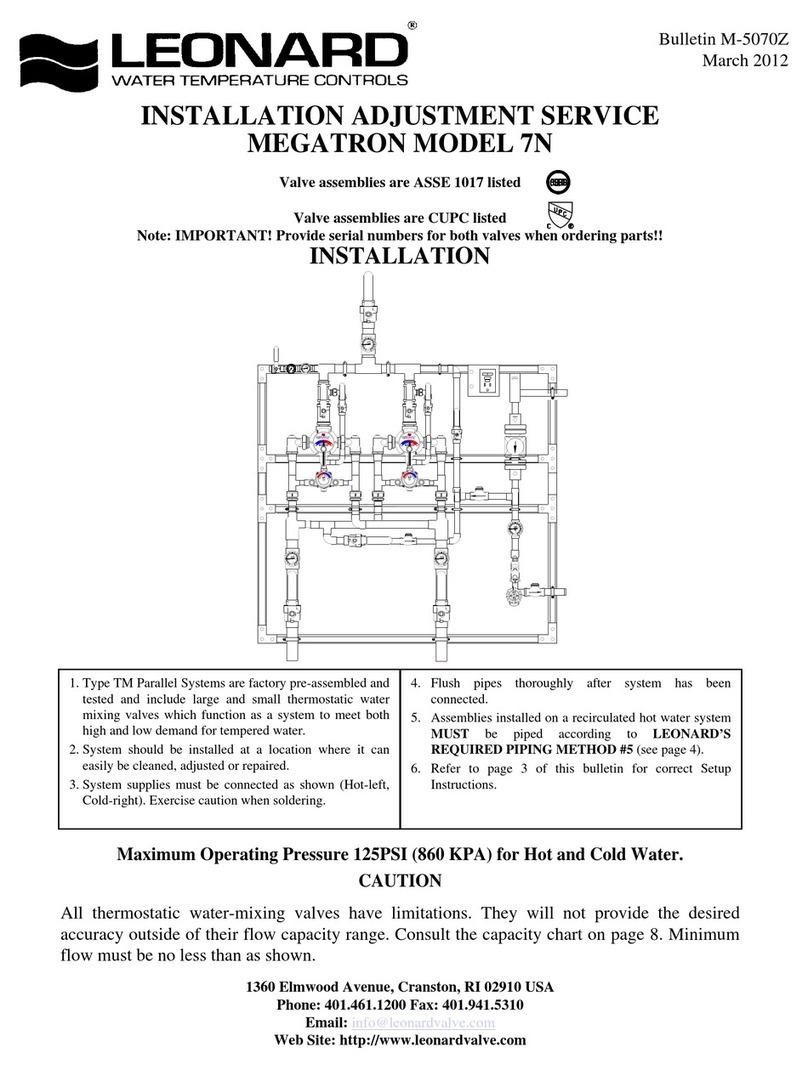

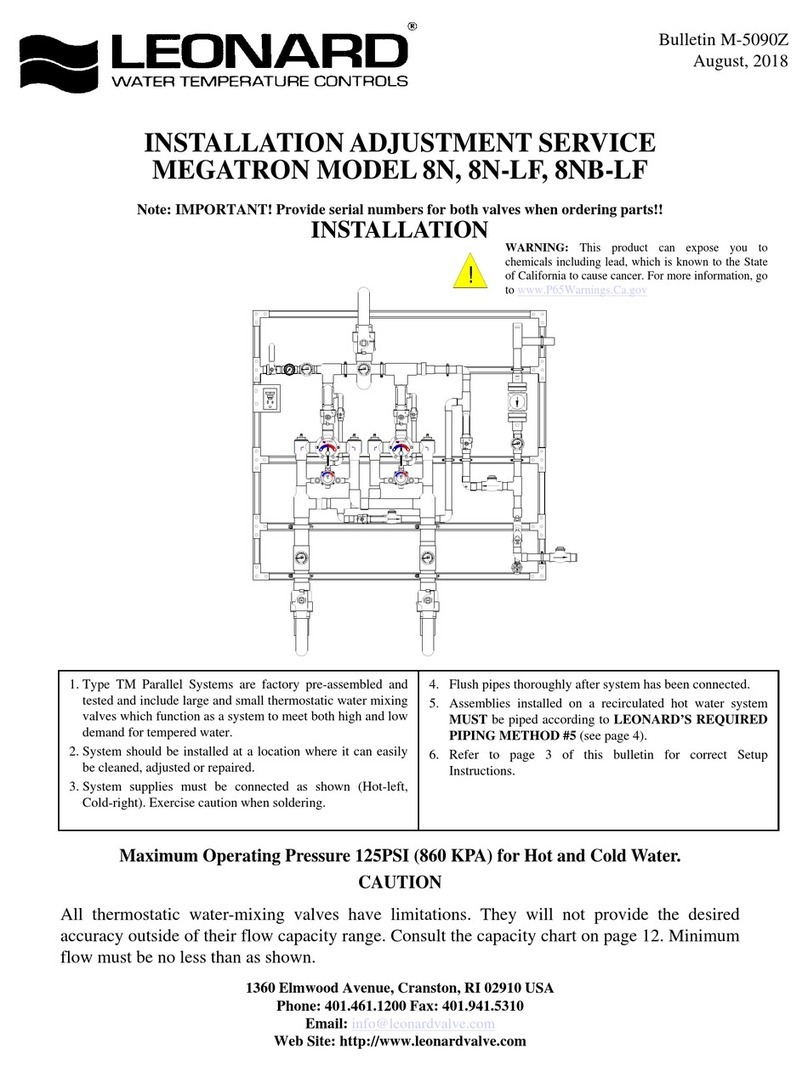

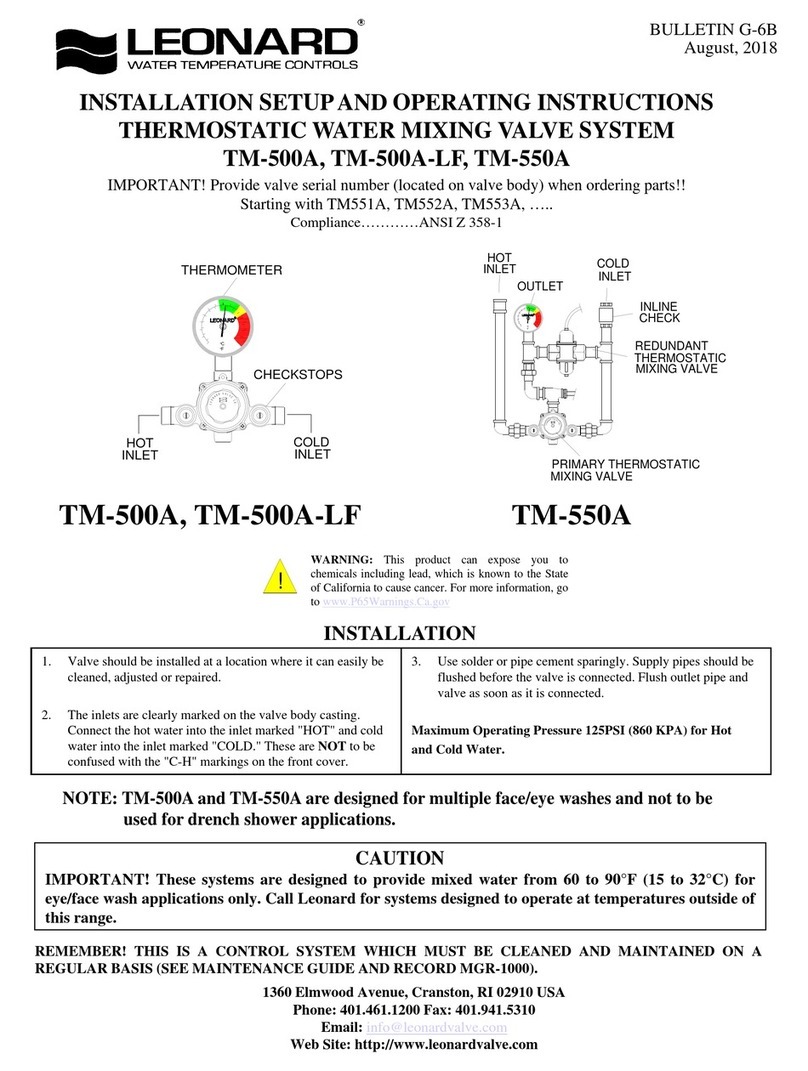

1. Determine what type of installation will be utilized.

a. standard installation with plasterguard/mounting bracket.

b. thin wall installation with mounting bracket.

c. valve only installation with plasterguard (service stops

or check stops are recommended).

2. Install hot to the left inlet and cold to the right inlet (see H and C

marks on valve body).

3. Thread sealant, or solder flux must be used sparingly. After

installation, flush pipes thoroughly (remove internal parts if

necessary), to eliminate debris that may become lodged on the

working parts of the valve.

4. Shower only applications require the bottom outlet to be plugged,

tub only applications require the top outlet to be plugged. A tub

diverter is required for tub/shower combinations.

5. Apply foam pointer gasket to wall flange. Mount wall flange to the

valve body with the vandal proof wall flange screws provided.

6. We recommend to seal the flange to the wall with silicone to

prevent water from penetrating the wall.

7. Check high temperature limit stop (see instructions, page 2).

8. Attach the knob to the valve stem using the vandal proof pointer

screw and washer. Turn knob clockwise to “OFF” on the dial

plate.

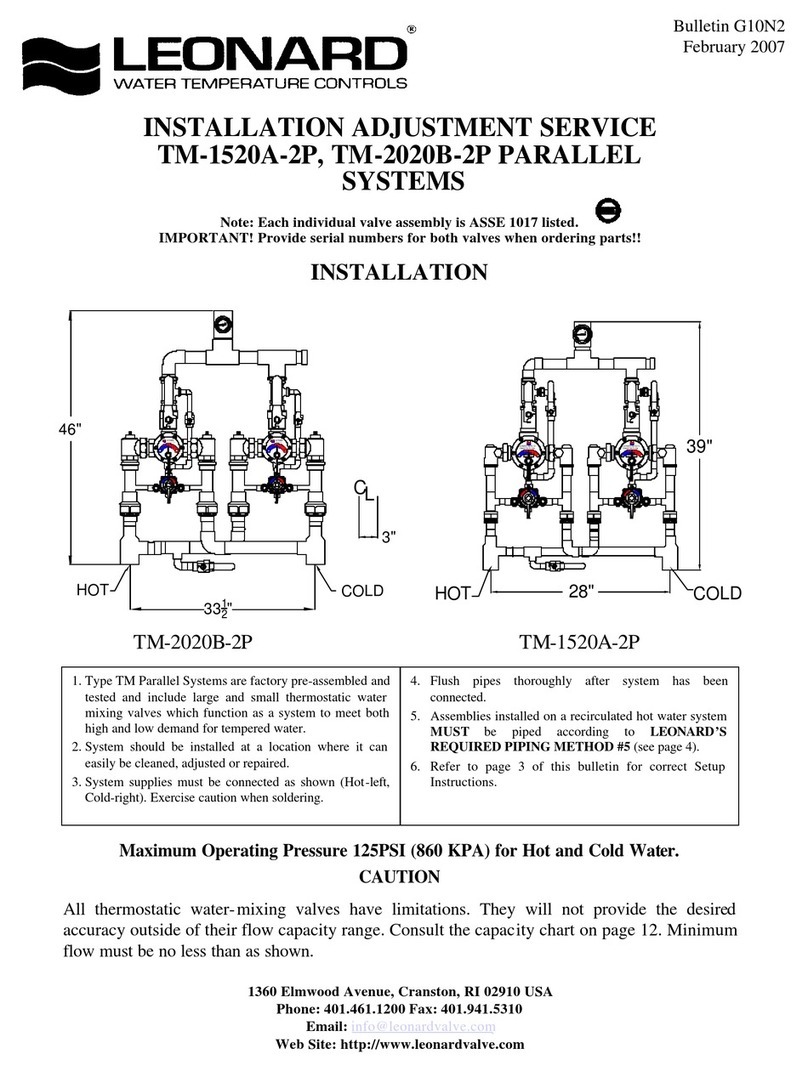

A INSTALLATION THROUGH

WALL WITH SERVICE

STOPS OR CHECKSTOPS.

1. Cut finished hole in wall 6” (152 mm)

max. diameter.

2. Install plaster mask/mounting bracket

over body of valve, and line up holes

with the holes on the valve body tabs.

3. Finish wall flush with plaster mask

front.

4. Remove and discard plaster mask.

C INSTALLATION

WITHOUT SERVICE

STOPS OR CHECKSTOPS

1. Cut finished hole in wall to 4”

(102mm) max. diameter.

2. Break away mounting bracket from

plaster mask and discard mounting

bracket. Install plaster mask over

valve body

3. Finish wall.

4. Remove and discard plaster mask.

1016

B) INSTALLATION FOR

FIBERGLASS, METAL OR

PLASTIC ENCLOSURES.

1/16” (1.6mm) to 1/8” (3.2mm)

1. Cut finished hole in enclosure to 5”

(127mm) max. diameter.

2. Break away plaster mask from

mounting bracket, discard plaster

mask and install mounting bracket

over valve body. Line up holes of

mounting bracket with the holes on

the valve body tabs.

3. Install escutcheon and dial plate over

enclosure by securing with screws

furnished.

I. "Ligature resistant" disclaimer

NOTE: This product has been designed to

reduce the likelihood that it can be used as a

mechanism for hanging.

II. "Not a substitute" disclaimer

This product IS NOT A SUBSTITUTE for the

evaluation, treatment or appropriate

supervision of persons at risk of suicide.

WARNING: This product can expose you to

chemicals including lead, which is known to the State

of California to cause cancer. For more information, go

to www.P65Warnings.Ca.gov

!