7

Operation

Before Operation

As with all mechanical tools, use reasonable care during

operation. Inspect the work area and machine before

operation. Be sure that all operators of this equipment are

trained in safety and general use. Be sure all operators have

read and understand the Owner's Manual.

Before operation, always:

1. Check the unit for loose hardware.

2. Check the engine oil level. Add oil if necessary.

3. Check the engine gasoline level. Add gasoline if

necessary. Replace old or bad gasoline.

4. Inspect the operation area conditions. Sod should not be

too dry, nor too wet. Sod should be damp. Sod that is too

dry can damage the blade. Sod that is too wet may cause

slippage.

5. Inspect the operation area for obstacles. Remove

obstacles that may damage the blade.

General Operation

1. Position the unit on sufficiently firm (but damp), flat soil.

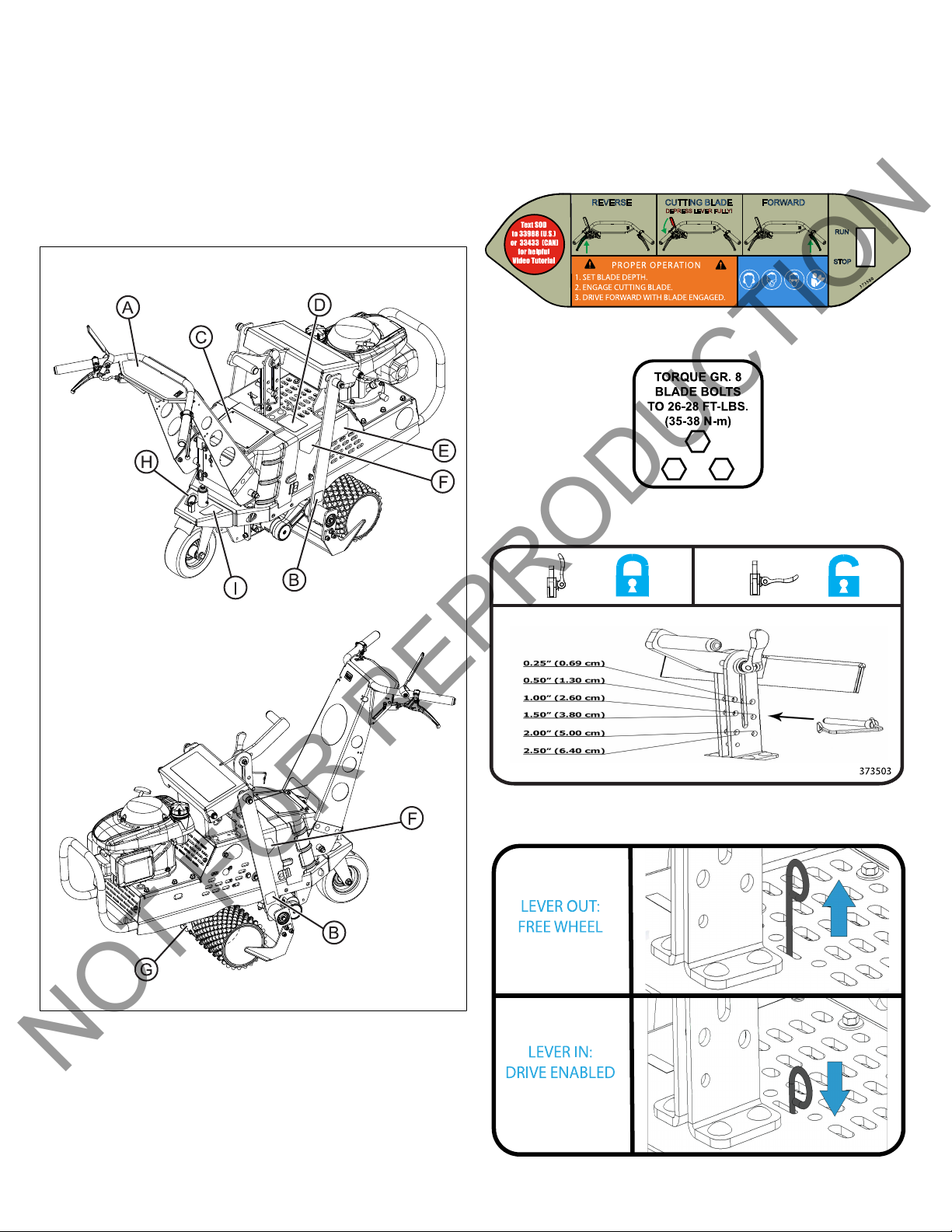

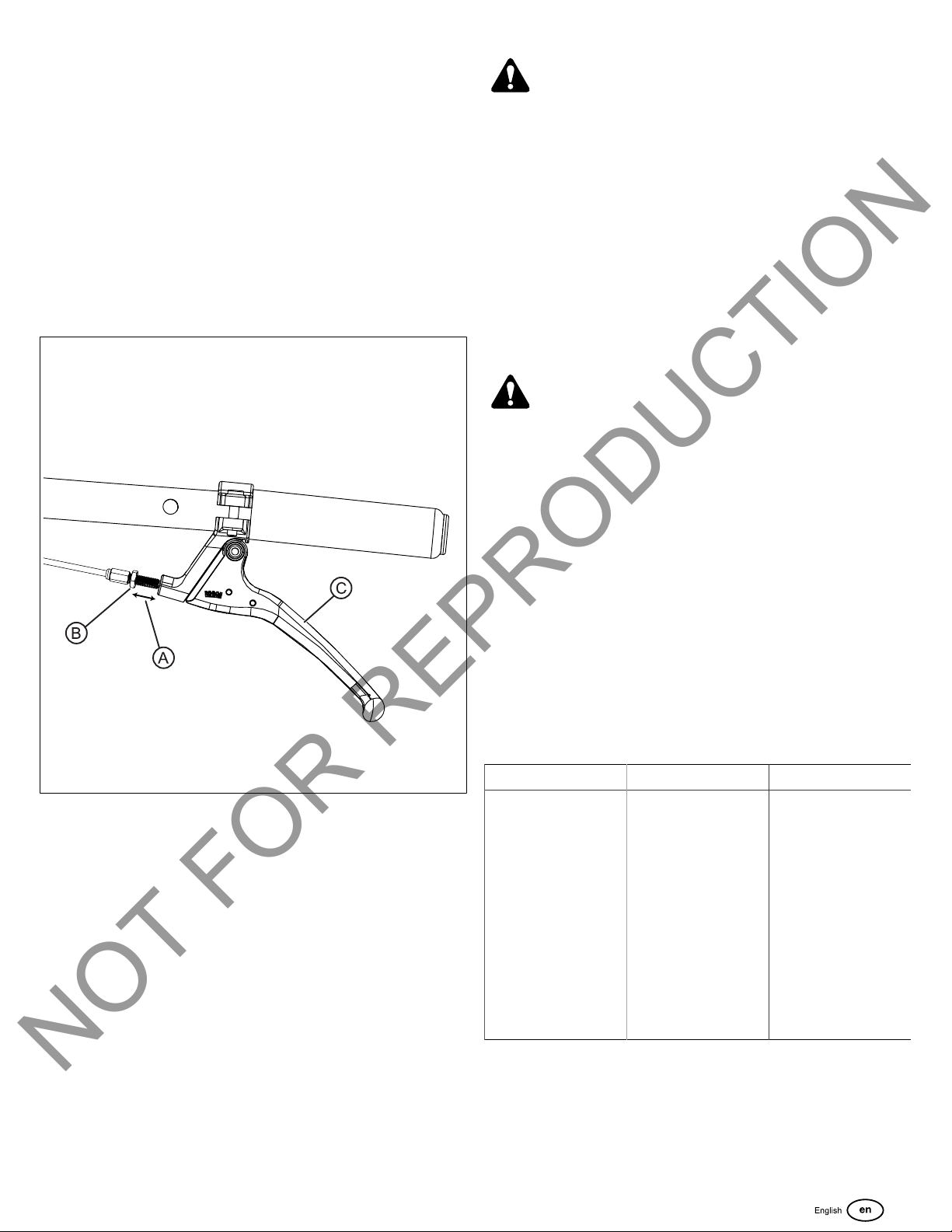

2. Select desired cutting depth. Insert the depth control pin

into the desired position on the blade height adjuster. See

the Blade Height Adjustertopic under the Features and

Controls section.

Note:Do not adjust cutting depth during operation. Park, turn

off the unit, then adjust cutting depth.

Note:Sod should be cut leaving a minimum amount of dirt

(1/4”-3/8”) attached to the roots. This minimizes its weight for

removal and encourages faster growth when reused.

3. Start the engine. Push the throttle lever down completely,

then pull the recoil handle to start the engine. Under cold

conditions, choke the engine before attempting to start.

See the Engine Controls section.

4. Check the unit for excessive vibration. If there is no

excessive vibration, continue to the next step.

WARNING

Do not operate the unit if excessive vibration occurs. If

excessive vibration occurs, immediately shut off the engine.

Check for a damaged or worn blade, loose hardware, or

lodged foreign objects. If you cannot find the source of

excessive vibration, contact your Authorized Service Dealer.

5. To begin cutting operation, firmly grasp both handles and

fully depress the blade engage lever. Rock back on the

handles to allow the blade to cut into the sod. Keep the

blade engage lever fully depressed at all times during

operation.

6. Begin driving the unit. Depress the right handle to move

forward. Depress the left handle to move in reverse. As

ground conditions allow, increase or decrease the ground

speed of the unit. To gradually increase speed, gradually

depress the lever. The unit operates at maximum speed

with the lever fully depressed. The unit operates at

minimum speed with the lever minimally depressed.

7. Cut sod in strips. At the end of a strip, fully release the

blade engage lever. Then, fully release the drive lever

until the unit stops. Release the cam lever on the blade

height adjuster to unlock the blade. Pull up on the height

adjuster handle to raise the blade out of the sod. Lock the

blade into place.

8. Drive the unit to the next strip of sod to be cut. Stop the

unit, and lower the blade to desired depth using the blade

height adjuster. Resume cutting by fully depressing the

blade engage lever.

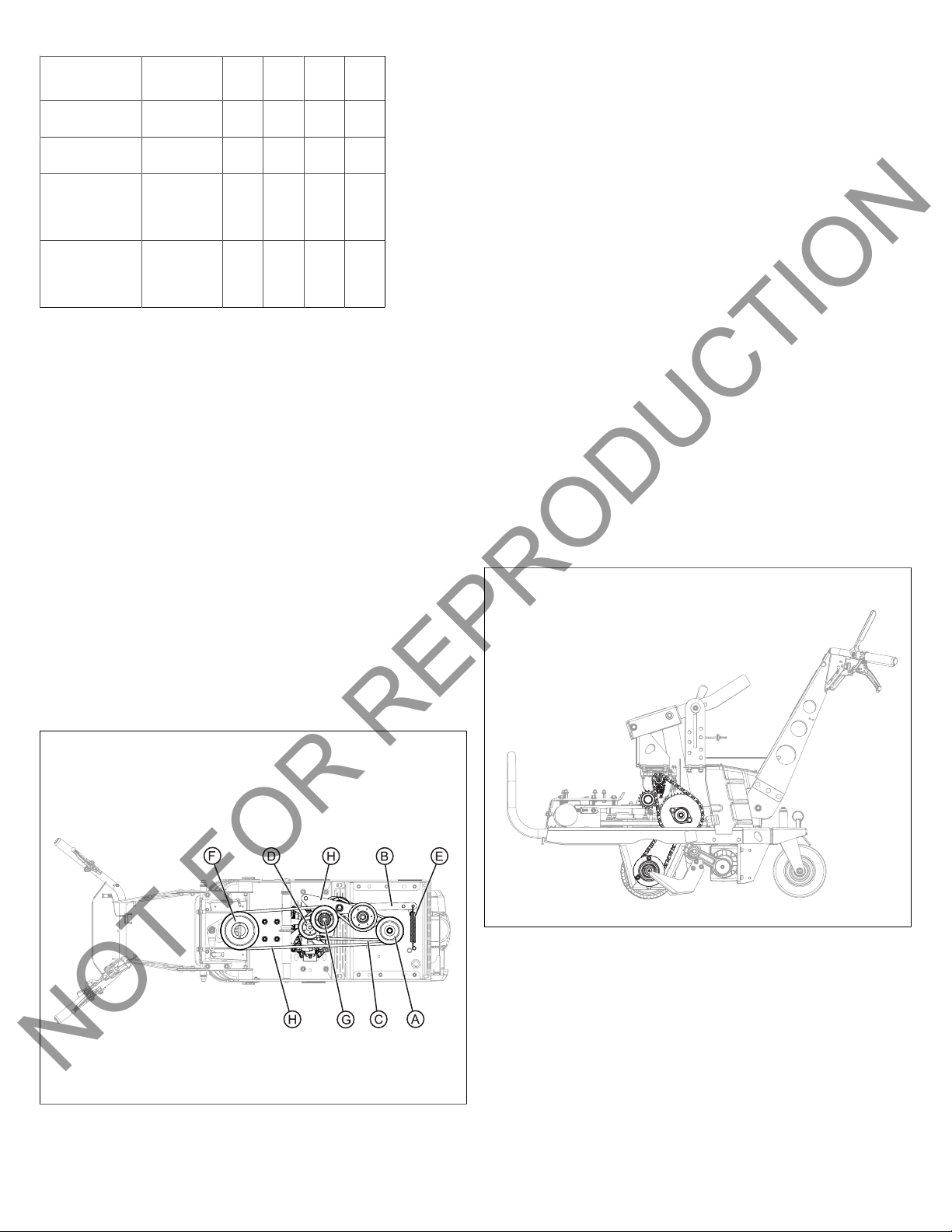

Periodic Maintenance

The blade, drive belts, and chains are normal wear items.

Inspect these items regularly and replace if worn. For engine

maintenance, please refer to the engine manufacturer

owner's manual.

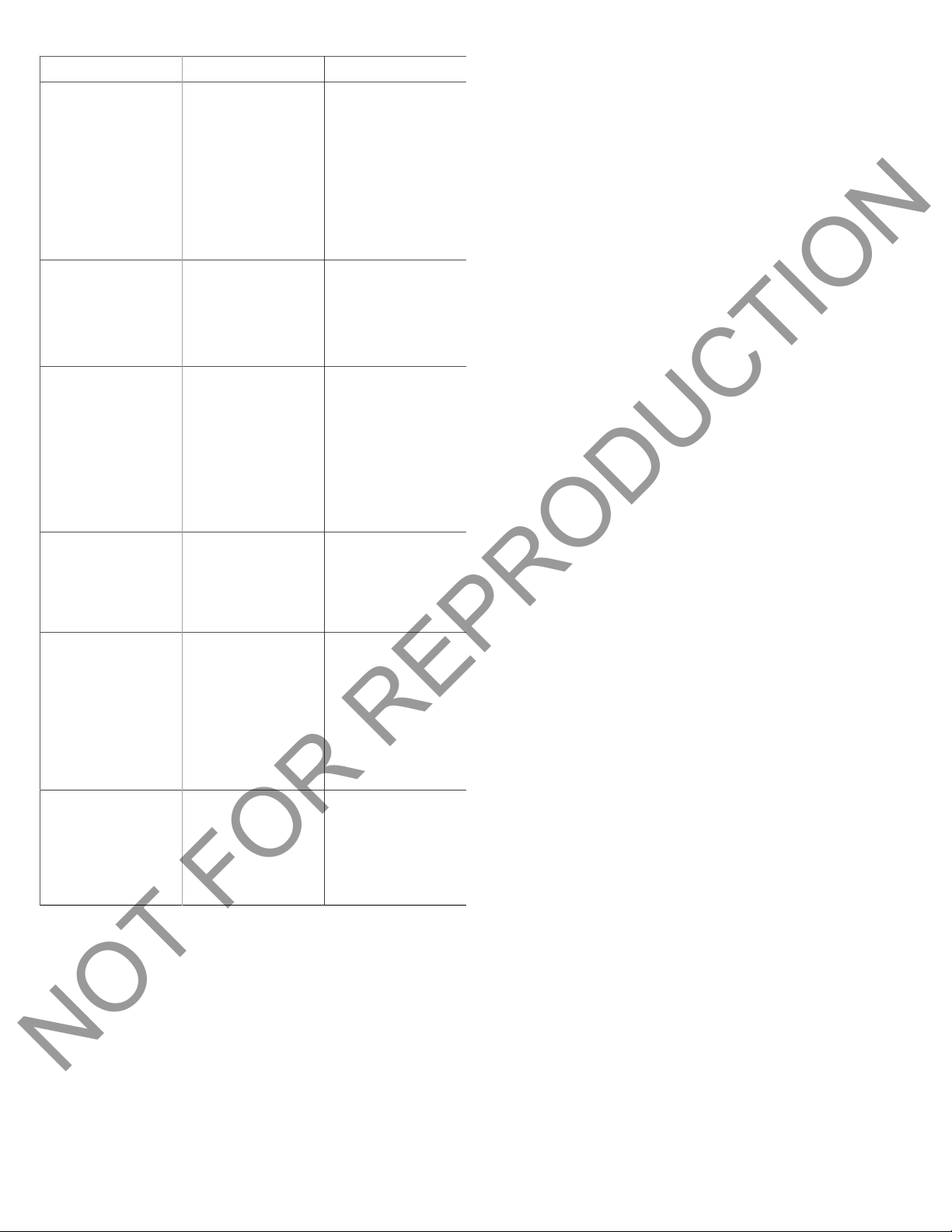

Maintenance

Operation

Each Use 25

Hrs

50

Hrs

100

Hrs

200

Hrs

Check engine

oil.

X

Check gasoline. X

Check for

loose, worn, or

damaged parts.

X

Check for

excessive

vibration.

X

Replace engine

oil.

X

Lubricate and

check chain

tension.

X

Sharpen cutting

blade.

X

Inspect axle

area between

wheels for debris

buildup. Clean if

necessary.*

X

Clean engine air

filter.

X

Grease jackshaft

bearings.

X

Check traction

belts. Adjust

or replace if

necessary.

XXX

Check rear

castor rod.

Adjust or replace

if necessary.

XXX

Check drive

cables for wear.

Adjust or replace

if necessary.

XXX