Contents

Page

Harvesting Unit Method of

Operation—Higher Yields Through

Narrow Corn Row Spacing.............................302

Operating the Harvesting

Unit—General Use .........................................302

Corn Harvesting Normal Harvesting

Conditions ......................................................302

Corn Harvesting Down Crop ............................303

Harvesting ShortStemmed Corn .......................304

Whole Crop Silage..............................................304

Technical Retrofitting to WholeCrop

Silage (WCS) Harvest ....................................306

Harvesting Crop with Very Close or

Wide Row Spacing (345, 360 and 375) ....... 3011

LengthofCut Adjustment with CLAAS

Forage Harvester .........................................3012

Length of Cut and Drum Speeds with

CLAAS Forage Harvester 860880

(Type 491) ....................................................3012

Length of Cut and Drum Speeds with

CLAAS Forage Harvester 830900

(Type 492) ....................................................3013

Length of Cut and Drum Speeds with

CLAAS Forage Harvester 830900

(Type 493) ....................................................3014

Length of Cut and Drum Speeds with

CLAAS Forage Harvester 930980

(Type 494) ....................................................3020

LengthofCut Adjustment with NEW

HOLLAND and CASE Forage Harvester .....3022

Length of Cut and Drum Speeds with

NEW HOLLAND and CASE Forage

Harvester......................................................3024

Length of Cut and Drum Speeds with

KRONE Forage Harvester ...........................3025

Adjusting Harvesting Unit Lateral Float

(Optional on 345 and 360, Standard

on 375) .........................................................3025

Adjusting the Feed Bars (330, 345 and 360)....3026

Adjusting the Feed Bars (375 up to

Construction Year 2009)...............................3027

Adjusting the Feed Bars (375 from

Construction Year 2010)...............................3028

Adjusting the Large Dividers.............................3029

Steering Assistance (Option)............................3030

Accessories

Special Kit for Row Guidance (Steering

Assistance).....................................................351

Automatic Height Control Kit ..............................351

Special Kit for WholeCrop Silage ......................351

Special Kit for Crops with Very Close

or Wide Row Spacing (345, 360 and 375) .....351

Special Kit for Quality of Cut...............................351

Troubleshooting

Correction of Defects on the Rotary

Harvesting Unit...............................................401

Page

Lubrication and Maintenance

Service Intervals.................................................451

Transmission Oil.................................................451

General View of Drives and Oil Levels

in the Rotary Harvesting Unit (Part 1) ............452

General View of Drives and Oil Levels

in the Rotary Harvesting Unit (Part 2) ............453

Overview of Oil Levels in Input Transmission.....454

Checking Oil Level and Changing Oil.................455

Lubricants...........................................................455

Coolant for Main Drive Friction Clutch................455

Alternative and Synthetic Lubricants ..................456

Mixing Lubricants................................................456

Lubricant Storage ...............................................456

Every 10 Hours U.J. Shaft................................456

Every 10 Hours Rotating Crop Divider .............457

Every 10 Hours Lower Rolls of Tilt

Frame (If Equipped, Standard on

Model 375) .....................................................457

Every 50 Hours Lower Axle Pin of

Hydraulic Cylinder and Frame Hinge Clutch ..457

Every 50 Hours Hinges of Outer Sections........458

Once Every Year RadialPin Clutch of

Gathering Drum..............................................458

Once Every Year Upper Rolls of Tilt

Frame (If Equipped, Standard on

Model 375) .....................................................458

Every 3 Years Change Coolant

of Main Drive Friction Clutch (If

Equipped, Standard on Model 375) ...............459

Before Start of Season .......................................459

Daily Maintenance (Or More Often if

Necessary) .....................................................459

Weekly Service.................................................4510

End of Season Maintenance ............................4510

Service

Metric Bolt and Screw Torque Values.................501

Main Drive Slip Clutches

WaterCooled (Optional on 345 and

360, Standard on 375) ...................................502

Removal of Slip Clutch .......................................503

Disassemble Slip Clutch.....................................505

Main Drive Friction Clutches (330, 345

and 360) .........................................................506

Gathering, Cross Feed and Feed Drum

RadialPin Clutches........................................507

Feeding and Cutting Area...................................508

Crop Feed Area................................................ 5011

Drive for DownCrop Auger ..............................5012

Storage

Storage at End of Harvesting Season ................551

Removing Harvesting Unit from Storage ............551

Specifications

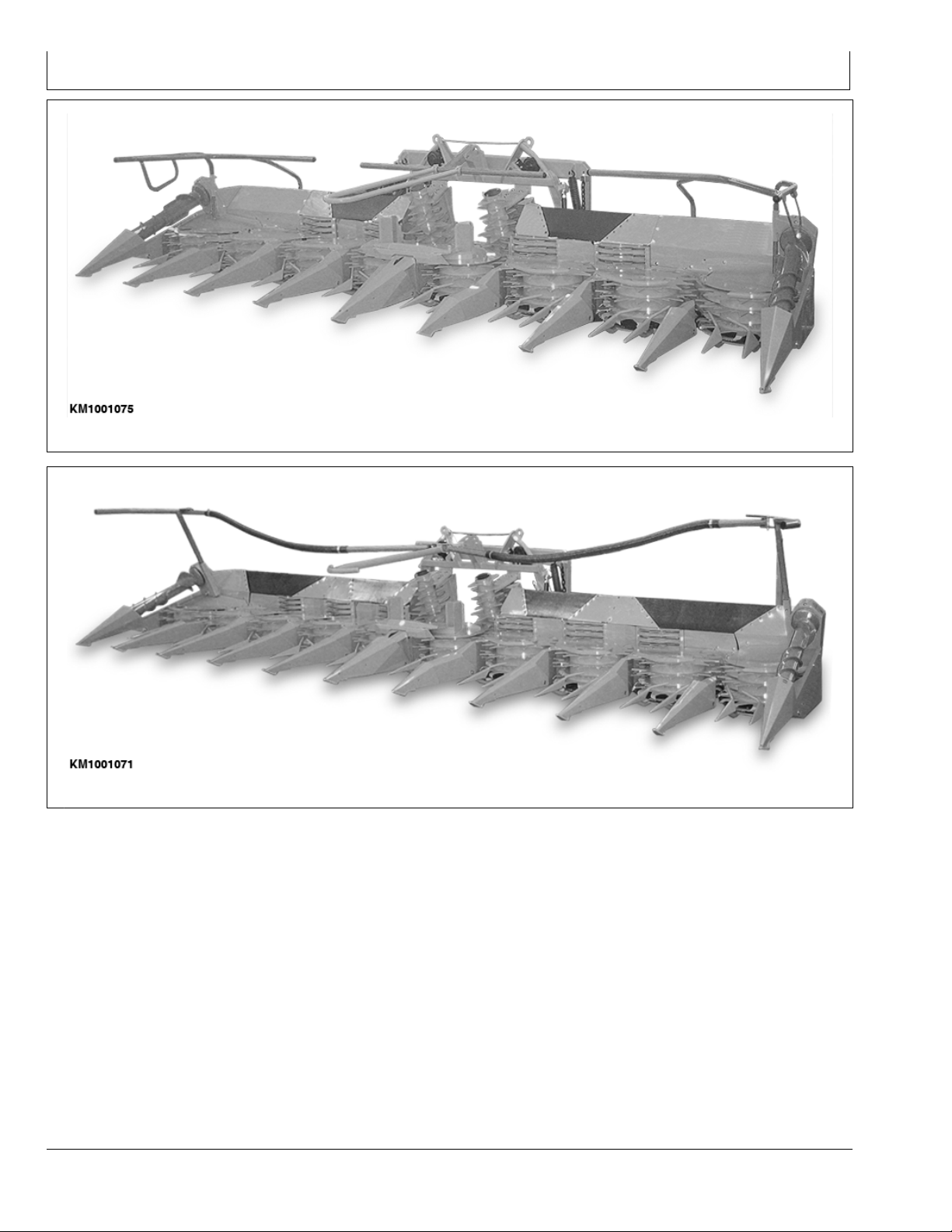

330 Rotary Harvesting Unit ................................601

Continued on next page

ii 040810

PN=2