Safety Disconnect Switch in Watertight Enclosure

Cat. Nos. MDS3-AC, MDS3-AX, MDS3-ST, MDS3-AST – Rated: 30/32A-600VAC Max.

Cat. Nos. MDS6-AC, MDS6-AX, MDS6-ST, MDS6-AST – Rated: 60A-600VAC Max.

Cat. Nos. MDS8-AC, MDS8-AX – Rated: 80A-600VAC Max.

Cat. Nos. MDS1-AC, MDS1-AX – Rated: 100A-600VAC Max.

Aux. Contact – Rated: 10A, 600V PK-A3191-10-00-0F

INSTALLATION INSTRUCTIONS ENGLISH

NOTES:

• For NEMA Type 4X, Type 12 and IP69K applications, enclosure must be mounted by means of mounting feet.

Do not drill or punch any holes into enclosure for mounting purposes.

•

Use of a UL Listed Watertight conduit fitting required to maintain the NEMA Type 4X, Type 12 and IP69K ratings.

Leviton conduit hubs (see Table 1) are rated for Type 4X and Type 12 applications. NOTE: If required, use only a listed/

certified breather drain rated for Type 4X, Type 12 and/or IP69K depending on required environmental application. Drill or

punch a 0.796

in

(20.2 mm) diameter hole through the bottom of the enclosure at the drill point provided.

• Mounting feet will accept up to 1/4 in (6 mm) screws.

• Drill points provided for conduit entry.

• When using top or side feed conduit entrance, always form condensation drip loops in wiring as shown.

powerswitch®

• Provides ON/OFF switched control of a directly connected load.

• Meets the requirements of Outdoor/Indoor (IP66, IP67, IP68, IP69K NEMA Type 3R, 4X, 12, 13 Watertight,

Corrosion-Resistant) and Indoor (Type 12 Dust-Tight) installations.

• The cover cannot be opened or removed when the handle is in the "ON" position.

• This product is certified by NSF®International, for use in food processing facilities.

• Normally open and normally closed auxiliary contact (if used) is rated 10A-600VAC.

FEATURES

INSTALLATION

STEPS

1. Mount Safety Disconnect Switch.

2. Remove enclosure cover by loosening two cover screws and lifting cover off hinges.

3. Remove switch (see REMOVE SWITCH section). This is recommended to prevent steel debris from entering

switch components.

4. Drill or punch conduit hole in desired location(s). See Table 1 for fitting size.

NOTE: If you have a slope top version (MDS3-ST, MDS3-AST, MDS6-ST, MDS6-AST), top feeding wiring is NOT

an option.

5. Install conduit fitting. Ensure "O" ring is properly seated and that the inside locking ring is seated tightly against the

inside surface of enclosure, to ensure proper grounding.

6. Re-install switch (see REPLACE SWITCH section).

7. Connect wires (see WIRING section).

8. Replace cover and hand thread screws to engagement.

NOTE: Handle must be in the "OFF" position to close cover. Tighten screws to 15-18 in.-lbs. (1.7-2.0 N-m) torque.

WARNINGS:

• TO AVOID FIRE, SHOCK, OR DEATH, TURN OFF POWER AT CIRCUIT BREAKER OR FUSE AND TEST THAT

POWER IS OFF BEFORE WIRING OR SERVICING DEVICE.

• TO AVOID FIRE, SHOCK, OR DEATH, DISCONNECT ALL POWER SUPPLIES TO ENCLOSURE BEFORE

EXPOSING INTERIOR. MORE THAN ONE SUPPLY DISCONNECT MAY BE REQUIRED TO DE-ENERGIZE THIS

EQUIPMENT BEFORE SERVICING.

• Separate over-current protection must be provided in accordance with the NEC® Article 220 or CEC, Section B,

as appropriate.

• This enclosure includes a lockout provision (in the OFF position) for a suitable padlock. USE ONLY a padlock with

a shackle diameter of 1/4 in. (6.35 mm.) to isolate power from the connected equipment, in compliance with OSHA

Lockout/Tagout Regulation 29 CFR Part 1910.147.

NOTE: Lockout feature does NOT interrupt the power supplied to the switch within the enclosure.

CAUTIONS:

• For installation ONLY by an electrician, in accordance with the National Electrical Code®(NEC), the Canadian

Electrical Code (CEC), and local codes.

• Use this device with copper or copper-clad wire only.

• Ensure that the rating marked on the device is correct for the intended installation.

• Suitable as Motor Disconnect on a circuit capable of delivering not more than:

- MDS3-AC, MDS3-AX - 10kA rms symmetrical amperes, 600V max., when protected by 60A, Class J fuses.

- MDS3-ST, MDS3-AST - 10kA rms symmetrical amperes, 600V max., when protected by 60A, Class J fuses.

- MDS6-AC, MDS6-AX - 100kA rms symmetrical amperes, 600V max., when protected by 100A, Class J or T fuses.

- MDS6-ST, MDS6-AST - 100kA rms symmetrical amperes, 600V max., when protected by 100A, Class J or T fuses.

- MDS8-AC, MDS8-AX - 100kA rms symmetrical amperes, 600V max., when protected by 100A, Class J or T fuses.

- MDS1-AC, MDS1-AX - 65kA rms symmetrical amperes, 600V max., when protected by 100A, Class J fuses.

Cat. No. Hub Trade Size Min QTY Required Leviton Cat. No. Conduit Hole

MDS3 3/4 in (19.05 mm) 1 HUB-034 1.05 in (26.67 mm)

MDS6 1-1/4 in (31.75 mm) 1 HUB-114 1.66 in (42.16 mm)

MDS8 1-1/4 in (31.75 mm) 2 HUB-114 1.66 in (42.16 mm)

MDS1 1-1/4 in (31.75 mm) 2 HUB-114 1.66 in (42.16 mm)

TABLE 1

NOTE: Use conductors with insulation rated 167

°

F (75

°

C) or higher, having sufficient ampacity in accordance with the 140

°

F (60

°

C) column of Table 310.15(B)(16) of the 2014 NEC®or Table 2 of the Canadian Electrical Code.

NOTE: Ensure that there are no stray conductor strands. DO NOT tin conductors.

1. WARNING: TO AVOID FIRE, SHOCK, OR DEATH, TURN OFF POWER AT CIRCUIT BREAKER OR FUSE AND TEST THAT POWER IS OFF BEFORE WIRING OR SERVICING DEVICE.

2. Strip all conductors approximately 1/2 in. (13.0 mm.).

NOTE: Refer to conductor sizes accepted for specific switch below.

3. Connect conductors per appropriate WIRING DIAGRAM (see reverse side).

4. Tighten all terminal screws per specific torque values below:

WIRING

WARNING:

RISK OF ELECTRIC SHOCK. TURN OFF POWER AT CIRCUIT BREAKER OR FUSE. DO NOT clean this product while undergoing electrical maintenance or service

.

CAUTION: Use only chemicals and cleaning solutions that are safe for use with plastics and rubber gaskets.

1. Follow general cleaning procedures established by your facility.

2. This product is certified by NSF®International to NSF/ANSI/3-A 14159-1.

3. Recommended cleaning procedures are:

a. Use hose-directed water or a cleaning solution to remove any collected contaminants from behind the enclosure. Ensure water completely cleans the area between the enclosure and the mounting surface.

b.

Use hose-directed water or a cleaning solution to remove soil and contaminants from the exterior surfaces of the enclosure.

c. CAUTION: DO NOT direct or concentrate high-pressure water or cleaning solution on the enclosure gasket seams, switch handle area, or exterior labels.

d. After cleaning the exterior surfaces of the enclosure, open the enclosure door and use a clean, damp cloth to manually remove any soil or contaminants from the gasket seam area and flanged lip on enclosure body.

e.If needed, the door can be lifted off the enclosure body to clean hinge cavities.

f.Use a dry, clean cloth to wipe away any excess water.

CLEANING PROCEDURES

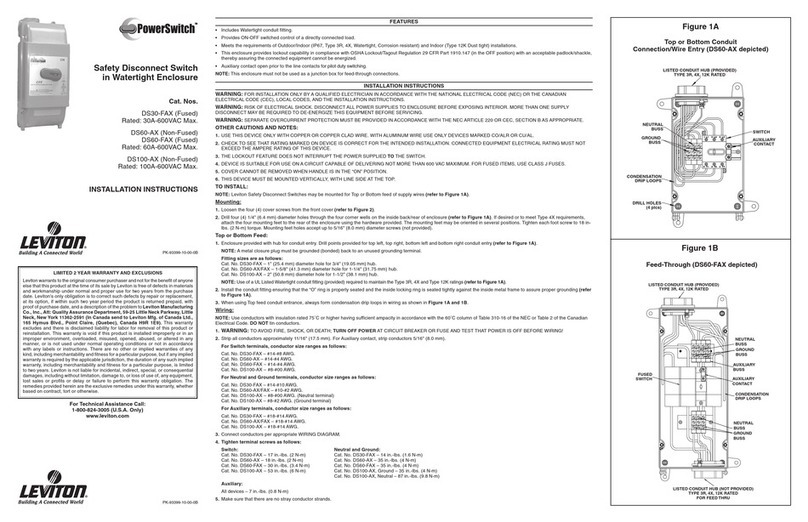

Captive cover screw (2)

Drill point for

breather drain

Drill point

Drill point

Mounting feet

ON/OFF

handle

Switch

DIN rail

Neutral bus

Ground bus

Mounting

holes for

enclosure

10.12 in.

Condensation

drip loops

4.75 in.

Top or bottom conduit connection/wire entry

MDS6-AX depicted (60A)

Condensation

drip loops

Listed/certified

conduit hub rated

type 3R, 4X, 12

(not provided)

Mounting

holes for

enclosure

8.38 in.

3.5 in.

Top or bottom conduit connection/wire entry

MDS3-AX depicted (30A)

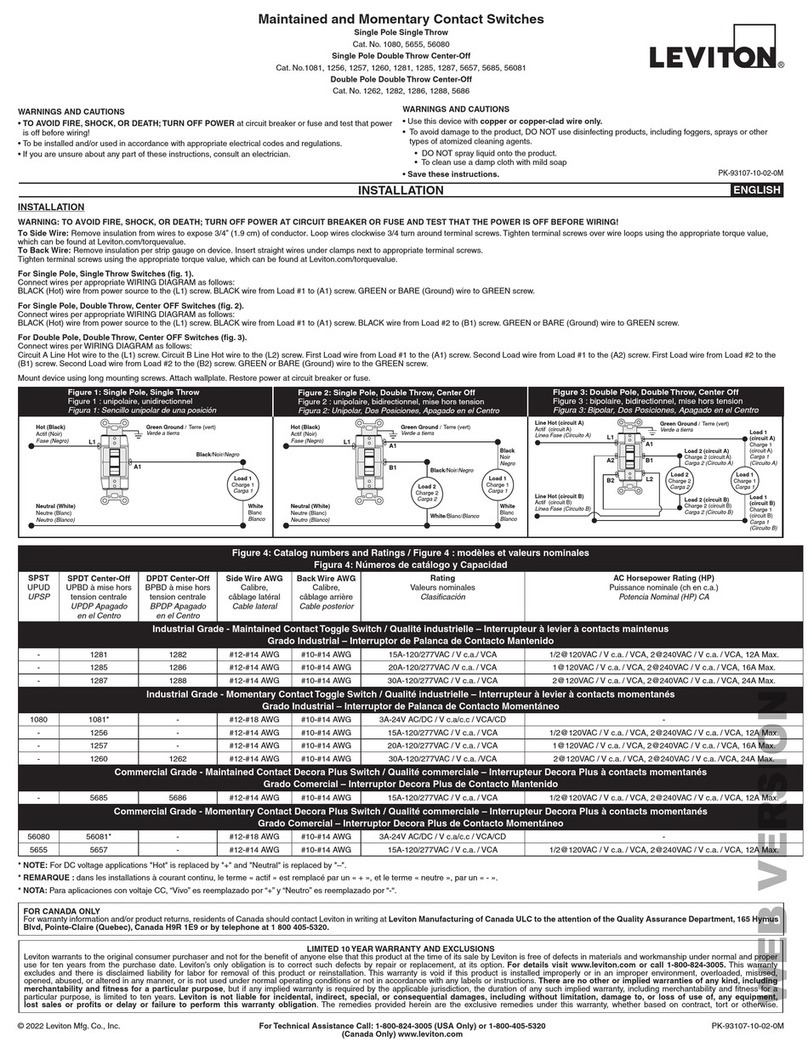

Feed through conduit connection/wire entry

MDS1-AX depicted (100A)

Lift cover

off hinges.

Breather drain (not supplied)

Dual top or bottom conduit connection/wire entry

MDS8-AX depicted (80A)

Listed/certified

conduit hub rated

type 3R, 4X, 12

(not provided)

Listed/certified

conduit hub rated

type 3R, 4X, 12

(not provided)

Mounting

holes for

enclosure

10.12 in.

Condensation

drip loops

4.75 in.

NOTE: Enclosure to be mounted such that drain

will always be on the bottom as shown.

Mounting

holes for

enclosure

11.38 in.

Condensation

drip loops

5.75 in.

Listed/certified

conduit hub rated

type 3R, 4X, 12

(not provided)

Note: Auxiliary

Contact, if used

Note: Auxiliary

Contact, if used

Note: Auxiliary

Contact, if used Note: Auxiliary

Contact, if used

Note: Auxiliary

Contact, if used

1

2

3

4

5

6

G

G

L

G

T

N

N

W

B

120 VAC 1 Ø

277 VAC 1 Ø

1

2

3

4

5

6

N

N

LL

G

G

G

T

240 VAC 1 Ø

480 VAC 1 Ø

600 VAC 1 Ø

1

2

3

4

5

6

N

N

X Y Z

G

G

G

T

240 VAC 3 Ø

480 VAC 3 Ø

600 VAC 3 Ø

1

2

3

4

5

6

N

N

G

G

LL

G

T

W

B

120/240 VAC 1 Ø

1

2

3

4

5

6

XYZ

G

G

G

T

N

N

W

B

120/208 VAC 3 ØY

277/480 VAC 3 ØY

347/600 VAC 3 ØY

13

14

13

14

13

14

13

14

13

14

Note: Auxiliary Contact,

if used

Note: Auxiliary Contact,

if used

Note: Auxiliary Contact,

if used

Note: Auxiliary Contact,

if used

Note: Auxiliary Contact,

if used

WIRING DIAGRAMS

Break All Lines