OVERSIDE WORK RAIL SYSTEM SIZE 1 - B10465 iss.1 | 3

Please read these instructions carefully before installing, operating or servicing this equipment. These

instructions MUST be provided to the user of this equipment. The user must read and understand the

instructions before using this equipment. Manufacturer’s instructions must be followed to ensure correct use and

maintenance of this equipment. Alterations or misuse of this equipment, or failure to follow these instructions,

may result in a fall or failure to arrest a fall leading to serious injury or death.

PLEASE RETAIN THESE INSTRUCTIONS

1 - Introduction

Thank you for choosing Lewmar. Lewmar products are world renowned for their quality, technical innovation and

proven performance. With a Lewmar product you will be provided with many years of outstanding service.

Important information about this manual

Throughout this manual, you will see safety and product damage warnings.

You must follow these warnings carefully to avoid possible injury or damage.

2 - Description and Purpose

WARNING!

The Lewmar Overside Work Rail System is a personal suspension system for the liing, lowering and traversing

of persons performing maintenance operations. It enables safe access whilst working at height. It is not to be

used for liing equipment or any other purpose.

This system is CE-certified and has been successfully tested against the requirements in European standard EN

795 Class D editions 1996 and 2012. It has also been successfully tested against the requirements in Lewmar

Test specification TS-LEW-15, which was specifically developed for testing personal suspension systems,

including rescue, and specifies requirements well in excess of those found in EN 795.

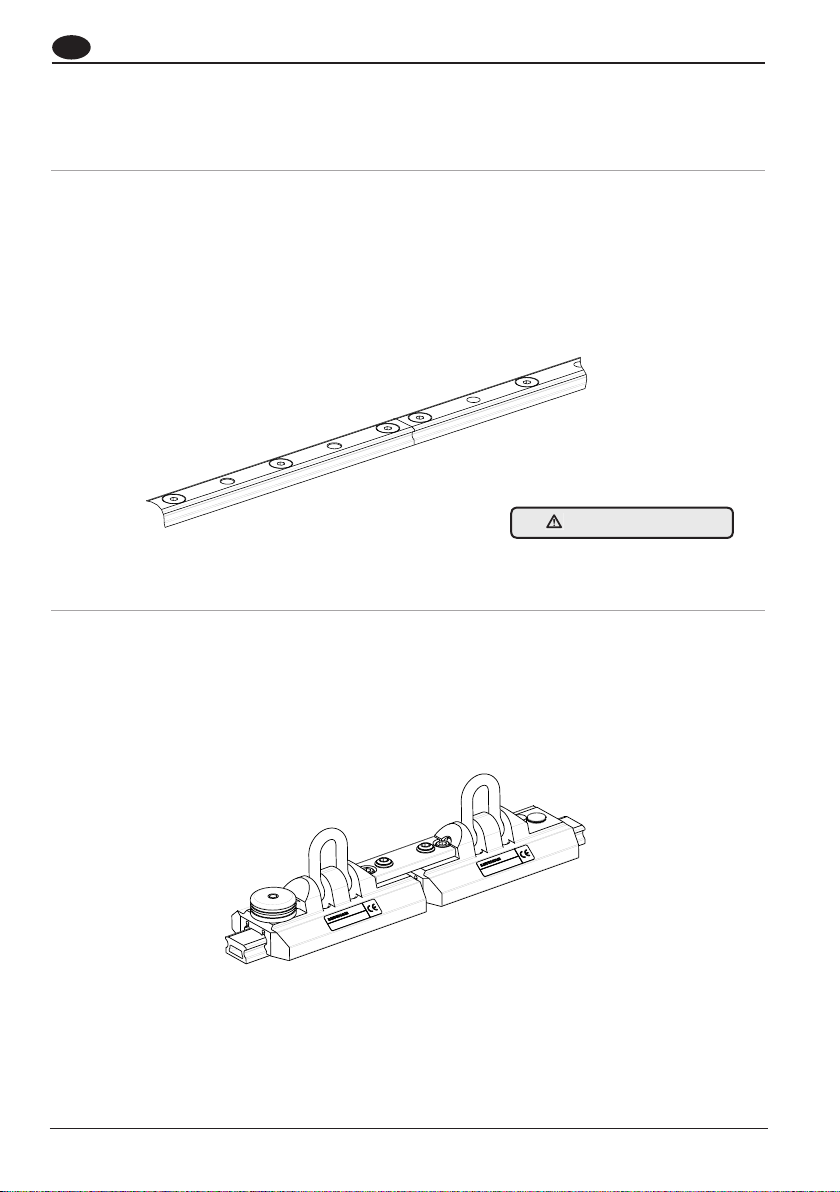

The system consists of aluminium track sections which are joinable to form a continuous span of rail. This is

fixable to a structure in the horizontal plane, whether that structure is part of a sea vessel, building, steelwork,

air or land vehicle or the like and the course of the rail follows the contour of the structure to which it is fixed.

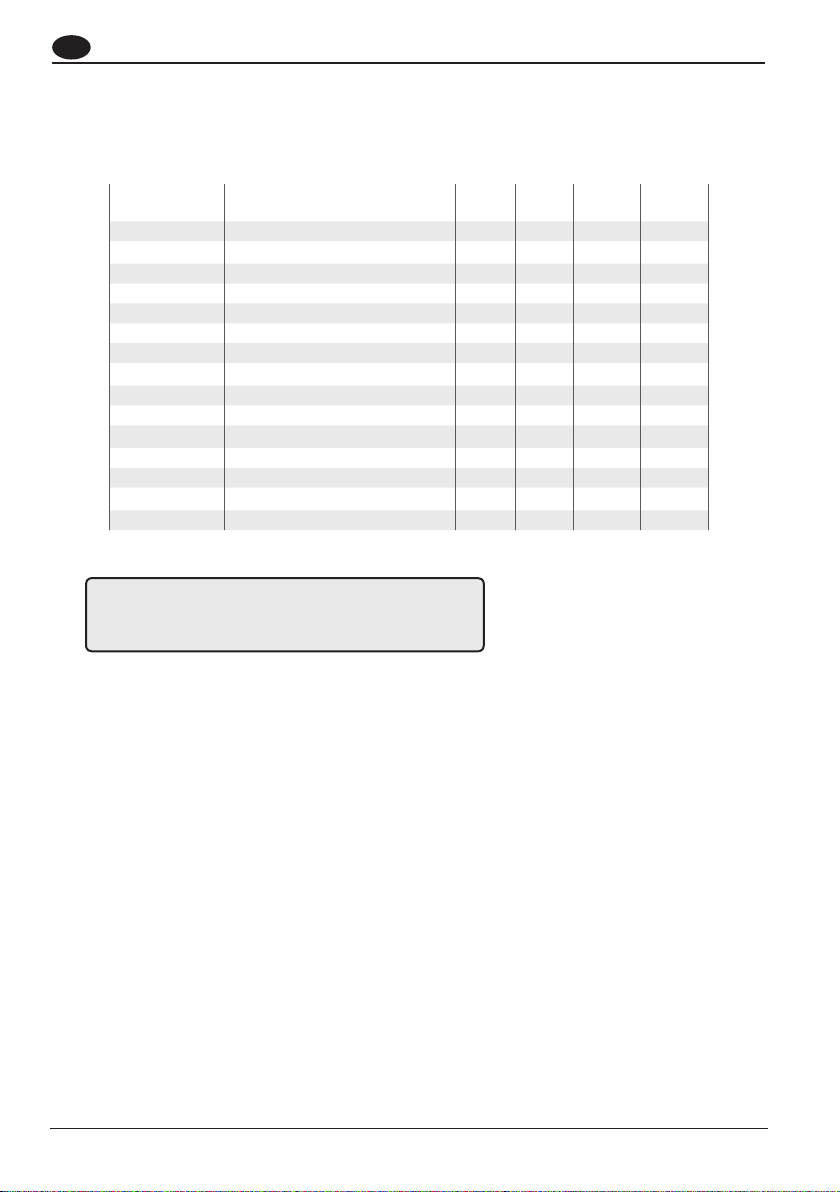

Cars can be engaged on and can slide along the rail. End-stops are fixed to the ends of the rail span to prevent

inadvertent disengagement of the cars.

A person may li or lower themselves in the vertical plane by attaching a liing-lowering device and rope to the

shackle of a car, together with a seat or support harness. Also, they may traverse horizontally from one position

to another along the span of the rail by virtue of the car’s sliding capability.

Consequently, suspended access can be gained to any point below the rail span. This can be extremely useful in

situations where conventional access methods such as ladders and platforms cannot be utilised.

Lewmar tracks and car are not compatible with those of any other manufacture.

Only use CE Certified Lewmar products (Page 6) for overside working.