• Securely attach the electrical part cover to the indoor unit and the service panel to the outdoor unit.

- If the electrical part cover of the indoor unit and the service panel of the outdoor unit are not

attached securely, it could result in a fire or electric shock due to dust, water, etc.

• Always install an earth leakage circuit breaker and a dedicated switching board.

- No installation may cause a fire and electrical shock.

• Do not keep or use flammable gases or combustibles near the air conditioner.

- Otherwise, it may cause a fire or the failure of product.

• Ensure that an installation frame of the outdoor unit is not damaged due to use for a long time.

- It may cause injury or an accident.

• Do not disassemble or repair the product randomly.

- It will cause a fire or electrical shock.

• Do not install the product at a place that there is concern of falling down.

- Otherwise, it may result in personal injury.

• Use caution when unpacking and installing.

- Sharp edges may cause injury.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress

air or Oxygen and Do not use Flammable gases. Otherwise, it may cause fire or explosion. There is

the risk of death, injury, fire or explosion.

• Consult your local dealer regarding what to do in case of refrigerant leakage.

When the air conditioner is to be installed in a small room, it is necessary to take proper measures

so that the amount of any leaked refrigerant does not exceed the concentration limit in the event of

a leakage. Otherwise, this may lead to an accident due to oxygen depletion.

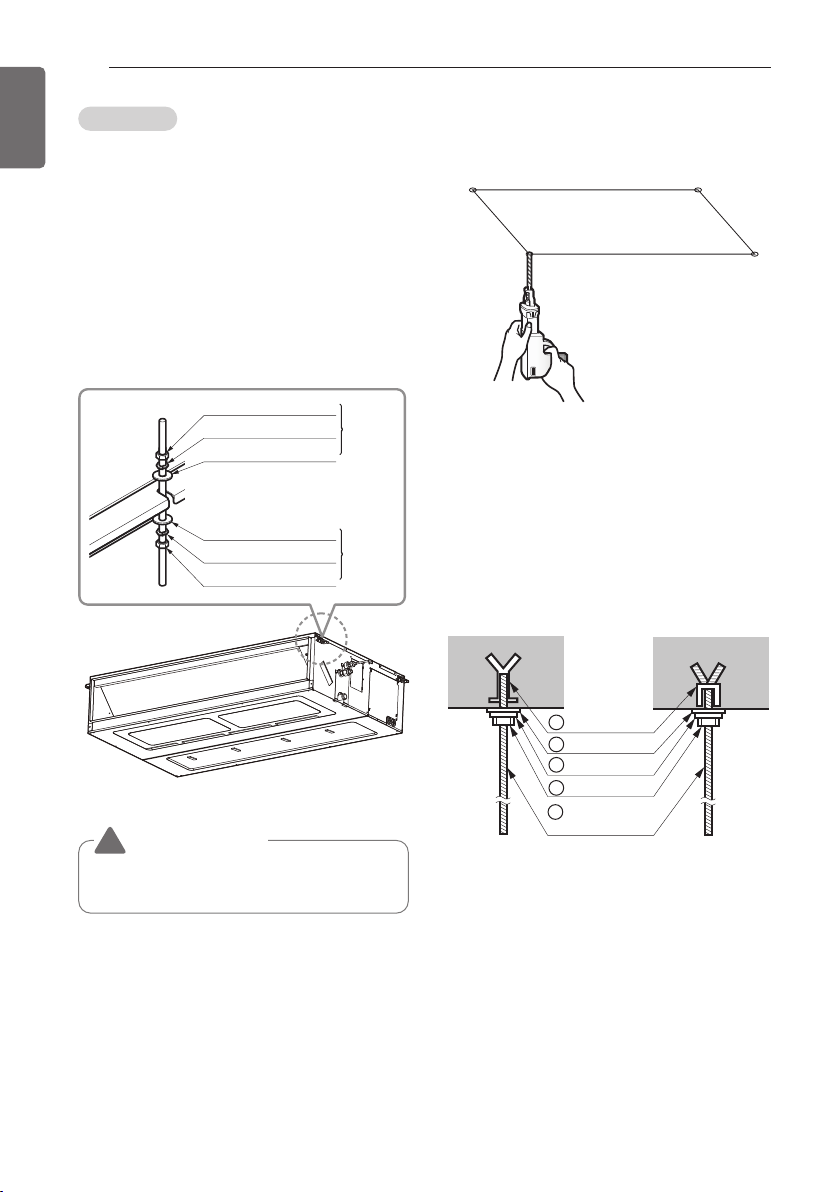

• Carry out the specified installation work after taking into account earthquakes.

Failure to do so during installation work may result in the unit falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is

carried out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or

fire.

• Be sure to switch off the unit before touching any electrical parts.

• Make sure that all wiring is secured, the specified wires are used, and that there is no strain on the

terminal connections or wires.

• If refrigerant gas leaks during installation, ventilate the area immediately.

Toxic gas may be produced if the refrigerant gas comes into contact with fire.

SAFETY INSTRUCTIONS

4

ENGLISH