6|INTRODUCTION

MULTI V Wall-Mounted Indoor Unit Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

© LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

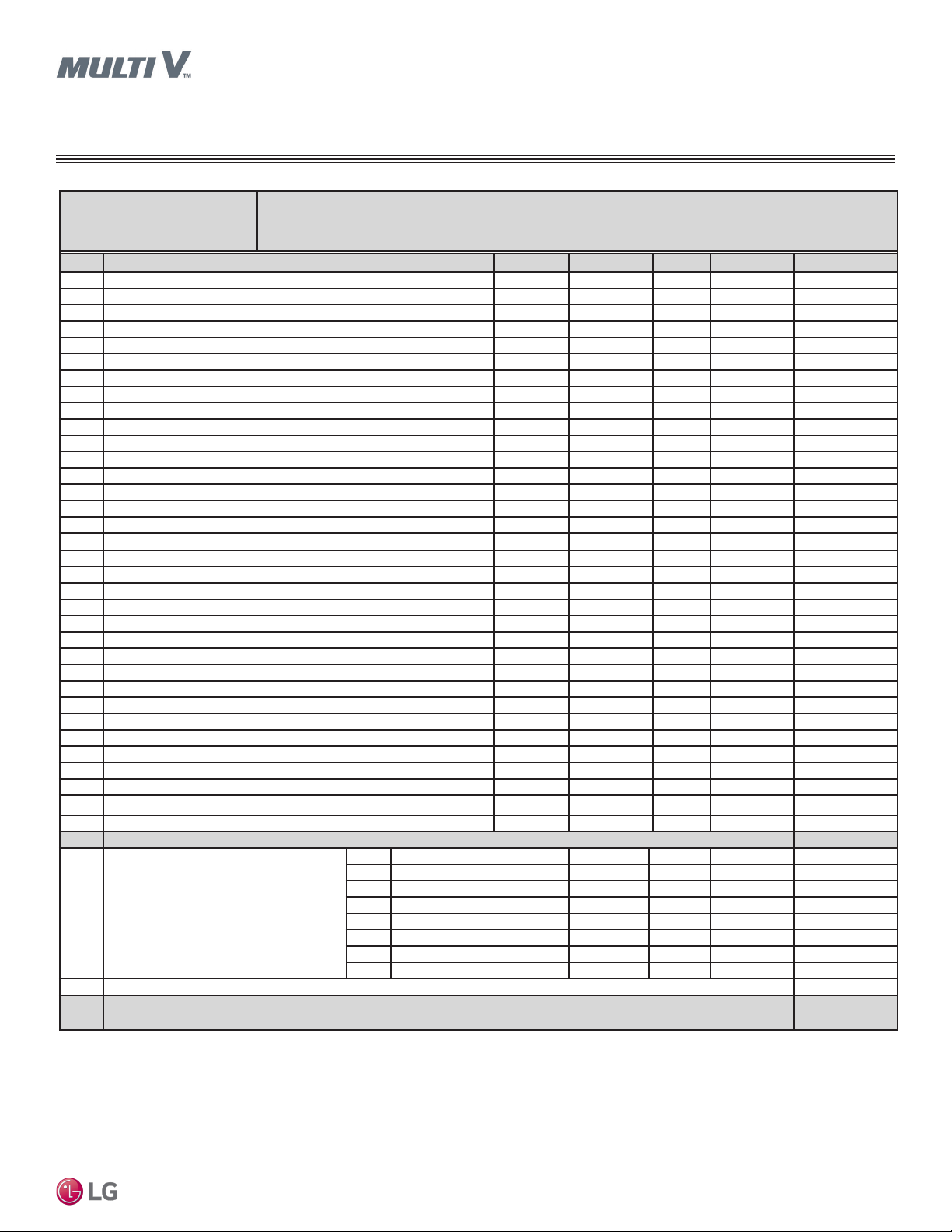

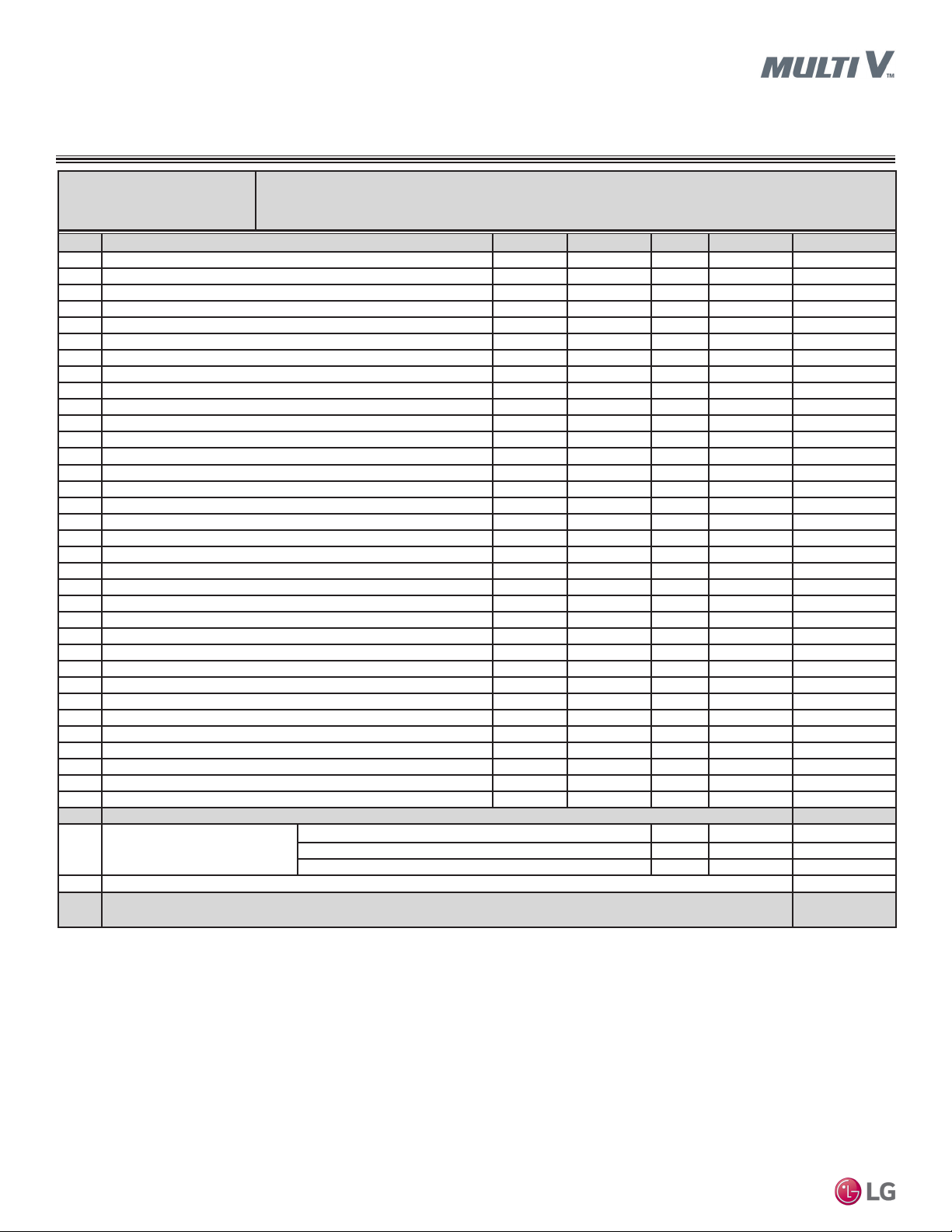

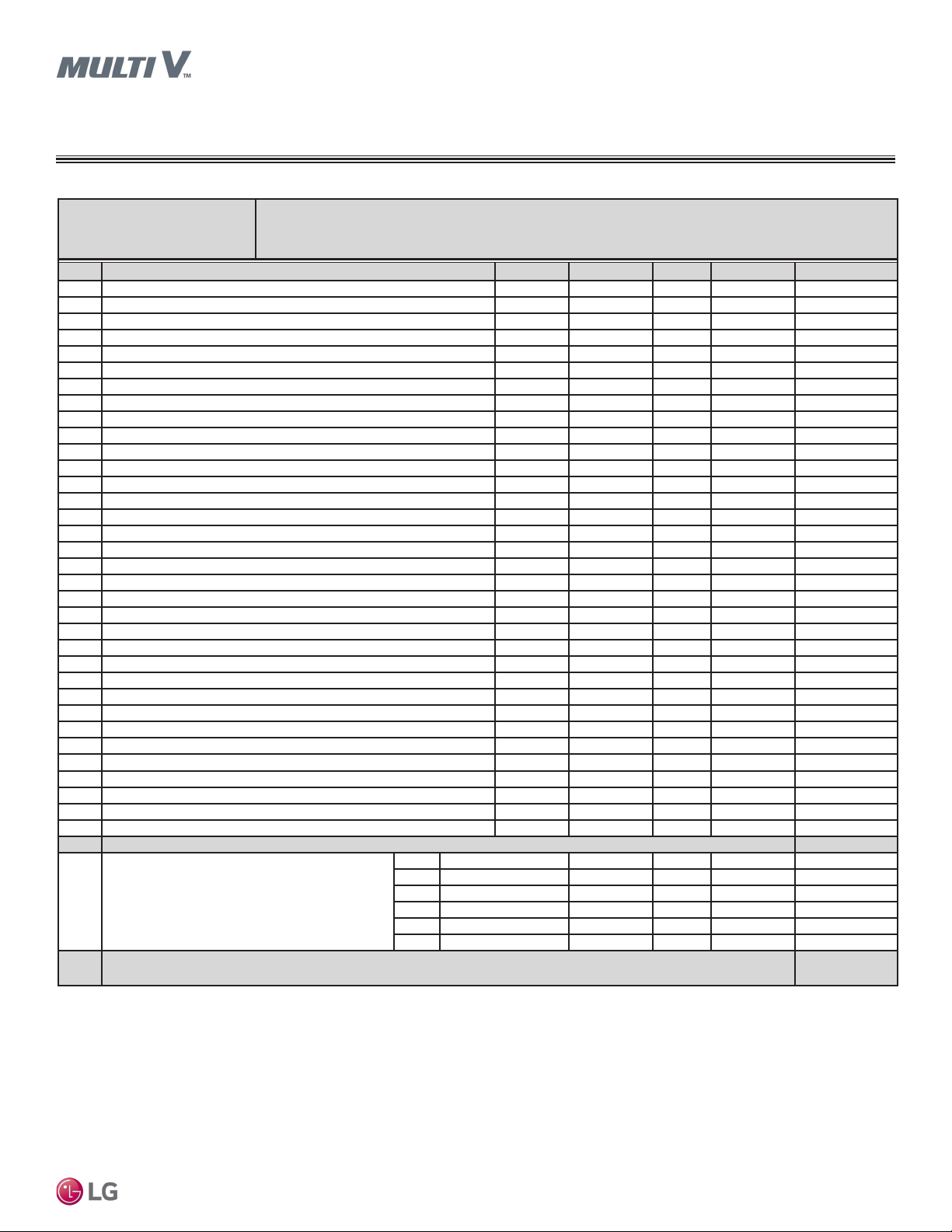

LATS Generates a Complete Project Report

LATS software also generates a report containing project design parameters, cooling and heating design data, system component perfor-

mance, and capacity data. The report includes system combination ratio and refrigerant charge calculations; and provides detailed bill of

material, including outdoor units, indoor units, control devices, accessories, refrigerant pipe sizes segregated by building, by system, by pipe

size, and by pipe segments. LATS can generate an Excel GERP report that can imported into the LG SOPS pricing and ordering system.

Proper Design to Install Procedure

LG encourages a two report design-to-install-procedure. After the

design engineer determines building / zone loads and other details,

the engineer opens the LATS program and inputs the project’s infor-

mation. When the design is complete, the “Auto Piping” and “System

Check” functions must be used to verify piping sizes, limitations, and

if any design errors are present. If errors are found, engineers must

adjust the design, and run Auto Piping and System Check again.

When the design passes the checks, then the engineer prints out

a project “Shop Drawing” (LATS Tree Diagram) and provides it to

the installing contractor. The contractor must follow the LATS Tree

Diagram when building the piping system, but oftentimes the design

changes on the building site:

• Architect has changed location and/or purpose of room(s).

• Outdoor unit cannot be placed where originally intended.

• Structural elements prevent routing the piping as planned.

• Air conditioning system conflicts with other building systems

(plumbing, gas lines, etc.).

The contractor must mark any deviation from the design on the Shop Drawing, including as-built straight lines and elbows. This “Mark Up”

drawing must be returned to the design engineer or Rep, who must input contractor changes into the LATS file. (Copy the original LATS soft-

ware file, save and rename as a separate file, and modify all piping lengths by double-clicking on each length and editing information.) Like

the shop drawing, the Auto Piping and System Check must also be run on this new “As Built” drawing. The design engineer or Rep must then

provide the final As Built file to the contractor. The Mark Up version must be compared to the As Built version for:

• Differences in pipe diameter(s). If incorrect diameters have been installed, the piping must be changed out. If pipe diameters have changed,

check to see if Y-Branches will also need to be changed.

• Changes to outdoor unit and indoor unit capacities. Capacities changes may impact line length changes.

• Additional refrigerant charge quantity (“Trim Charge”). Trim charge will change if piping lengths and diameters change. The As Built version

must reflect installed piping lengths to ensure correct trim charge.

All documents submitted by the contractor, as well as the Shop Drawing and the As Built Drawing files must be provided for commissioning

purposes. Model and serial numbers for all system components must also be submitted. If the steps previously detailed are not followed,

and all documents are not provided to the commissioning agent, the project runs the risk of not being commissioned and voiding any limited

warranty LG offers on the equipment.

LG AIR CONDITIONER

TECHNICAL SOLUTION (LATS)

Figure 2: Example of a LATS Tree Diagram.