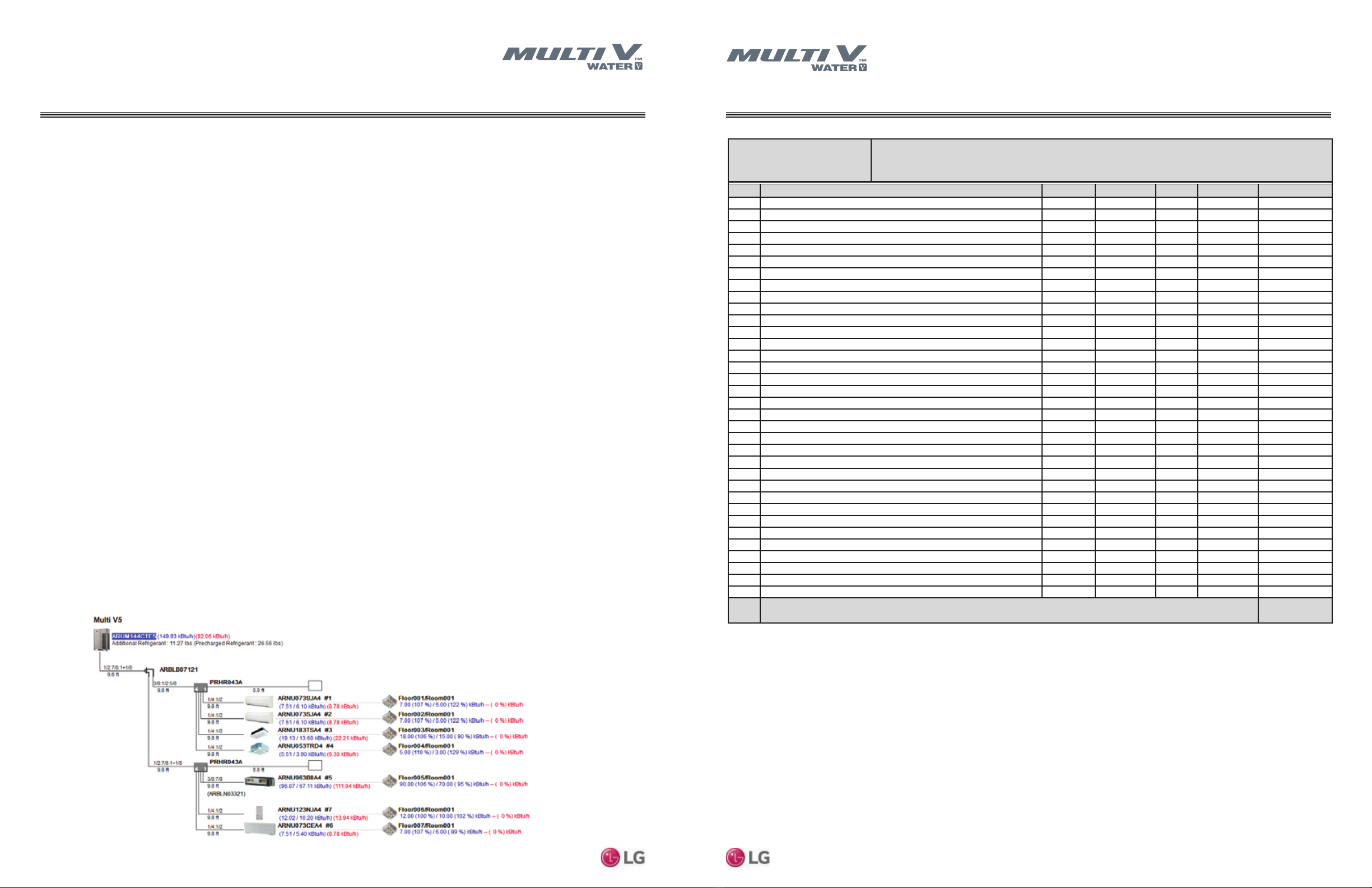

14 |WSU PRODUCT DATA WSU PRODUCT DATA | 15

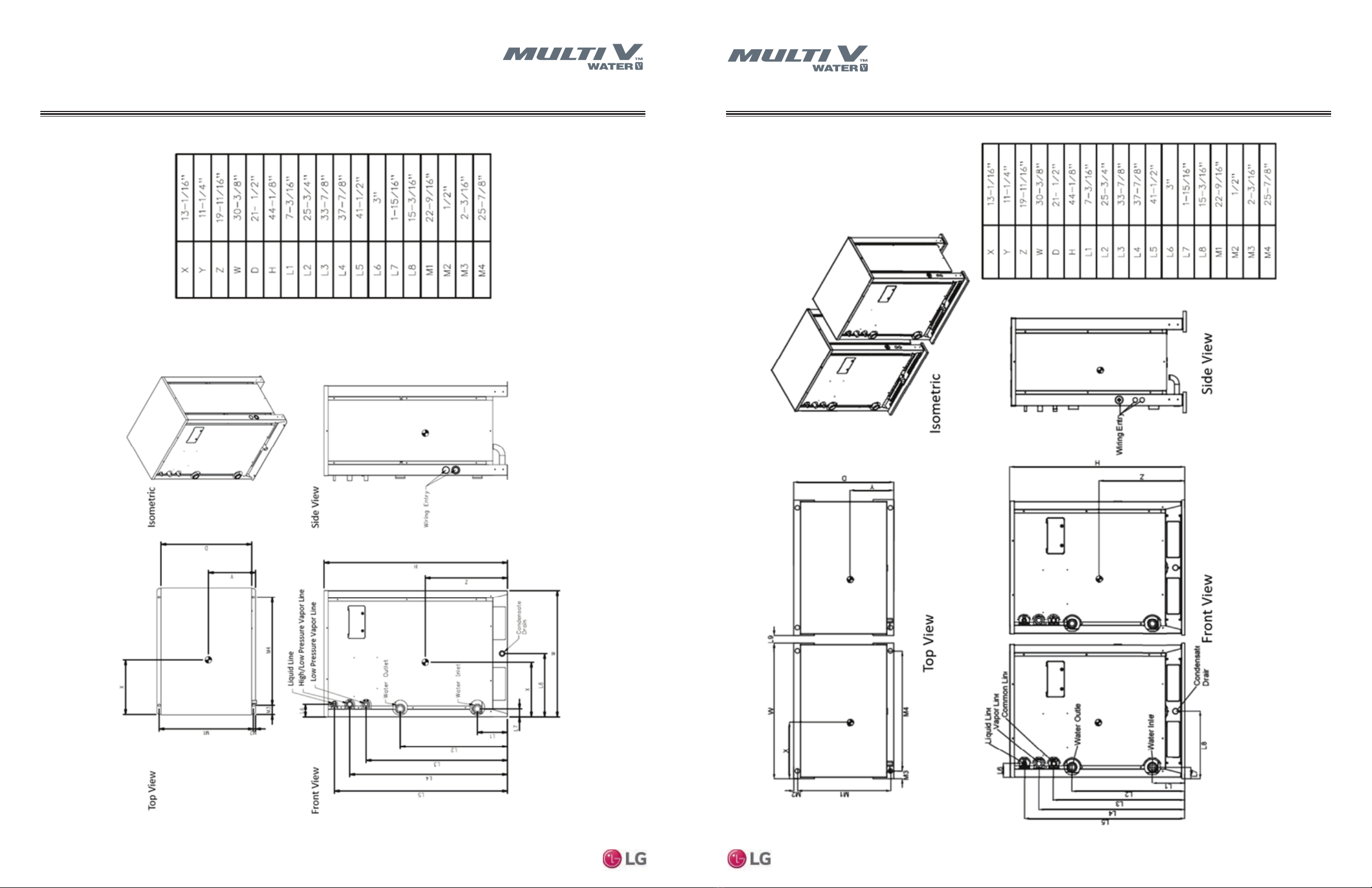

Water Source Unit Product Data

MULTI V Water V Water Source Unit Engineering Manual

© LG Electronics Canada, Inc., North York, ON Canada. All rights reserved. “LG” is a registered trademark of LG Corp. © LG Electronics Canada, Inc., North York, ON Canada. All rights reserved. “LG” is a registered trademark of LG Corp.

Table 2: Multi V Water V 575V Units

Combination Unit Model Number 20.0

ARWM240CAS5

24.0

ARWM288CAS5

28.0 Ton

ARWM336CAS5

Individual Component Model Numbers ARWM096CAS5 x 1

ARWM144CAS5 x 1 ARWM144CAS5 x 2 ARWM144CAS5 +

ARWM192CAS5

Cooling Performance

Nominal Cooling Capacity (Btu/h)1239,400 287,700 336,000

Heating Performance

Nominal Heating Capacity (Btu/h)1269,000 324,000 378,000

Operating Range (Entering Water Temperature)

Cooling (°F)223 – 113 23 – 113 23 – 113

Heating (°F) 14 – 113 14 – 113 14 – 113

Synchronous Operation (°F) 23 – 113 23 – 113 23 – 113

Compressor

Inverter Quantity HSS DC Scroll x 2

Oil/Type PVE/FVC68D

Unit Data

Refrigerant Type R410A

R410A Refrigerant Factory Charge (lbs) 9.9 + 9.9 9.9 + 9.9 9.9 + 9.9

Refrigerant Control/Location EEV/Indoor Unit

Max. Number Indoor Units/System239 45 55

Sound Pressure dB(A)3 Cooling/Heating 55 57 59

Net Unit Weight (lbs.) 348 + 348 348 + 348 348 + 348 309 + 309

Shipping Weight (lbs.) 370 + 370 370 + 370 370 + 370

Communication Cables5,6 2 x 18 AWG

Heat Exchanger (Stainless Steel Plate)

Maximum Pressure Resistance (psi) 640 640 640

Flow at Rated Condition (GPM) 25.4 + 35.5 35.5 + 35.5 35.5 + 50.7

Range of Flow (GPM) 30.5 – 91.4 35.5 - 106.5 43.1 - 129.3

Total Heat of Rejection (Btu/h) 316,000 380,200 443,600

Total Heat of Absorption (Btu/h) 245,400 293,600 340,400

Pressure Drop (ft-wg) 3.51 + 6.50 6.50 + 6.50 6.50 + 12.61

Δt4(°F) 10.4 10.7 10.3

Piping for Heat Recovery Operation7

Liquid Line Connection (in., OD) 3/8 + 1/2 Braze 1/2 + 1/2 Braze 1/2 + 5/8 Braze

Low Pressure Vapor Line Conn (in., OD) 7/8 + 1-1/8 Braze 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 Braze

High Pressure Vapor Line Conn (in., OD) 3/4 + 7/8 Braze 7/8 + 7/8 Braze 7/8 + 1-1/8 Braze

Piping for Heat Pump Operation7

Liquid Line Connection (in., OD) 3/8 + 1/2 Braze 1/2 + 1/2 Braze 5/8 + 5/8 Braze

Low Pressure Vapor Line Conn (in., OD) 7/8 + 1-1/8 Braze 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 Braze

Piping for Water7

Water Inlet/Outlet Connection Size (in) (1-1/2 + 1-1/2 Fem) x2 (1-1/2 + 1-1/2 Fem) x2 (1-1/2 + 1-1/2 Fem) x2

Condensate Drain (in) 3/4 Female 3/4 Female 3/4 Female

Multi V Water V 575V Unit Specications

GENERAL DATA

1 Rated capacity is certified under AHRI Standard 1230. Ratings are subject to change without notice. Current certified ratings are

available at www.ahridirectory.org.

2 When entering water temperature is lower than 59ºF, variable water flow control kit PWFCKN000 is required.

3 Sound pressure levels are tested in an anechoic chamber under ISO 3745 standard.

4 Value is calculated as follows: Δt = Total Heat of Rejection/(Nominal Flow Rate x 500).

5 Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs / HRUs to be 18 AWG, 2-conductor,

twisted, stranded, shielded. Ensure the communication cable shield is properly grounded to the Master ODU chassis only.

Do not ground the ODU to IDUs / HRUs communication cable at any other point. Wiring must comply with all applicable local and

national codes.

6 Power wiring is field provided, solid or stranded, and must comply with the applicable local and national codes.

7 LG requires that LATS software be used on all projects to ensure correct line sizing. Designer must verify the shop drawing design

against the as built design using LATS. Contractor must also use LG manufactured Y-Branch and Header Kits only.

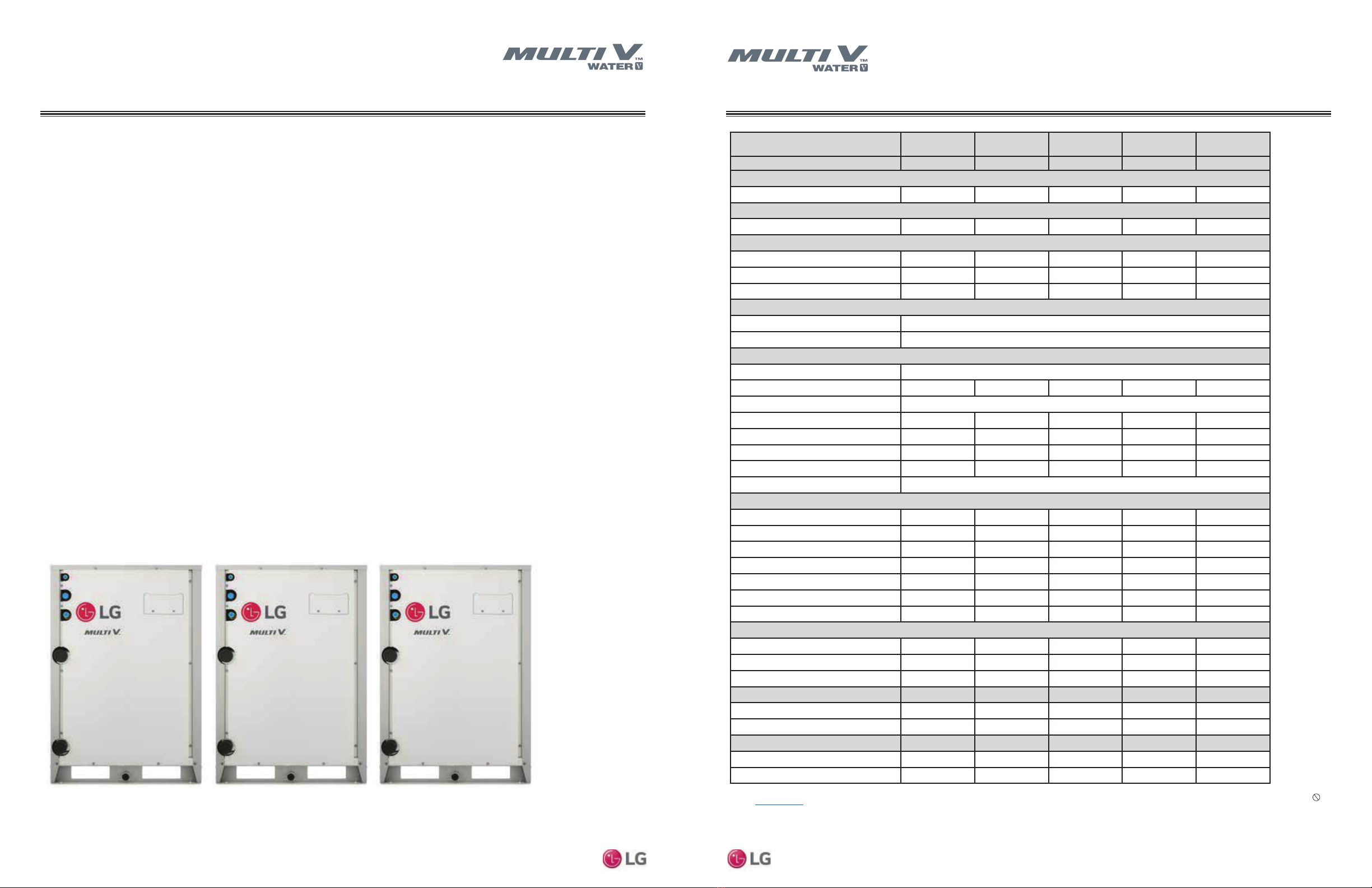

Table 3: Multi V Water V 575V Units

Combination Unit Model Number 36.0 Ton

ARWM432CAS5

40.0 Ton

ARWM480CAS5

48.0

ARWM576CAS5

Individual Component Model Numbers ARWM144CAS5 x 3 ARWM144CAS5 x 2

+ARWM192CAS5 x 1 ARWM192CAS5 x 3

Cooling Performance

Nominal Cooling Capacity (Btu/h)1430,500 472,500 571,200

Heating Performance

Nominal Heating Capacity (Btu/h)1486,000 536,000 642,000

Operating Range (Entering Water Temperature)

Cooling (°F)223 – 113 23 – 113 23 – 113

Heating (°F) 14 – 113 14 – 113 14 – 113

Synchronous Operation (°F) 23 – 113 23 – 113 23 – 113

Compressor

Inverter Quantity HSS DC Scroll x 3

Oil/Type PVE/FVC68D

Unit Data

Refrigerant Type R410A

R410A Refrigerant Factory Charge (lbs) 9.9 + 9.9 + 9.9 9.9 + 9.9 + 9.9 9.9 + 9.9 + 9.9

Refrigerant Control/Location EEV/Indoor Unit

Max. Number Indoor Units/System264 64 64

Sound Pressure dB(A)3 Cooling/Heating 59 61 63

Net Unit Weight (lbs.) 348 + 348 + 348 348 + 348 + 348 348 + 348 + 348

Shipping Weight (lbs.) 370 + 370 + 370 370 + 370 + 370 370 + 370 + 370

Communication Cables5,6 2 x 18 AWG

Heat Exchanger (Stainless Steel Plate)

Maximum Pressure Resistance (psi) 640 640 640

Flow at Rated Condition (GPM) 35.5 + 35.5 + 35.5 35.5 + 35.5 + 50.7 50.7 + 50.7 + 50.7

Range of Flow (GPM) 53.3 - 159.8 60.9 – 182.6 76.1 – 228.2

Total Heat of Rejection (Btu/h) 570,300 633,700 760,500

Total Heat of Absorption (Btu/h) 440,400 487,200 580,800

Pressure Drop (ft-wg) 6.50 + 6.50 + 6.50 6.50 + 6.50 + 12.61 12.61 + 12.61 + 12.61

Δt4(°F) 10.7 10.4 10.0

Piping for Heat Recovery Operation7

Liquid Line Connection (in., OD) 1/2 + 1/2 + 1/2 Braze 1/2 + 1/2 + 5/8 Braze 5/8 + 5/8 + 5/8 Braze

Low Pressure Vapor Line Conn (in., OD) 1-1/8 + 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 + 1-1/8 Braze

High Pressure Vapor Line Conn (in., OD) 7/8 + 7/8 + 7/8 Braze 7/8 + 7/8 + 1-1/8 Braze 1-1/8 + 1-1/8 + 1-1/8 Braze

Piping for Heat Pump Operation7

Liquid Line Connection (in., OD) 1/2 + 1/2 + 1/2 Braze 1/2 + 1/2 + 5/8 Braze 5/8 + 5/8 + 5/8 Braze

Low Pressure Vapor Line Conn (in., OD) 1-1/8 + 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 + 1-1/8 Braze 1-1/8 + 1-1/8 + 1-1/8 Braze

Piping for Water7

Water Inlet/Outlet Connection Size (in) (1-1/2 + 1-1/2 Fem) x3 (1-1/2 + 1-1/2 Fem) x3 (1-1/2 + 1-1/2 Fem) x3

Condensate Drain (in) 3/4 Female 3/4 Female 3/4 Female

Multi V Water V 575V Unit Specications

GENERAL DATA

1 Rated capacity is certified under AHRI Standard 1230. Ratings are subject to change without notice. Current certified

ratings are available at www.ahridirectory.org.

2 When entering water temperature is lower than 59ºF, variable water flow control kit PWFCKN000 is required.

3 Sound pressure levels are tested in an anechoic chamber under ISO 3745 standard.

4 Value is calculated as follows: Δt = Total Heat of Rejection/(Nominal Flow Rate x 500).

5 Communication cable between Master ODU to Slave ODU(s), and Master ODU to IDUs / HRUs to be 18 AWG, 2-con-

ductor, twisted, stranded, shielded. Ensure the communication cable shield is properly grounded to the Master ODU

chassis only. Do not ground the ODU to IDUs / HRUs communication cable at any other point. Wiring must comply

with all applicable local and national codes.

6 Power wiring is field provided, solid or stranded, and must comply with the applicable local and national codes.

7 LG requires that LATS software be used on all projects to ensure correct line sizing. Designer must verify the shop

drawing design against the as built design using LATS. Contractor must also use LG manufactured Y-Branch and Header

Kits only.