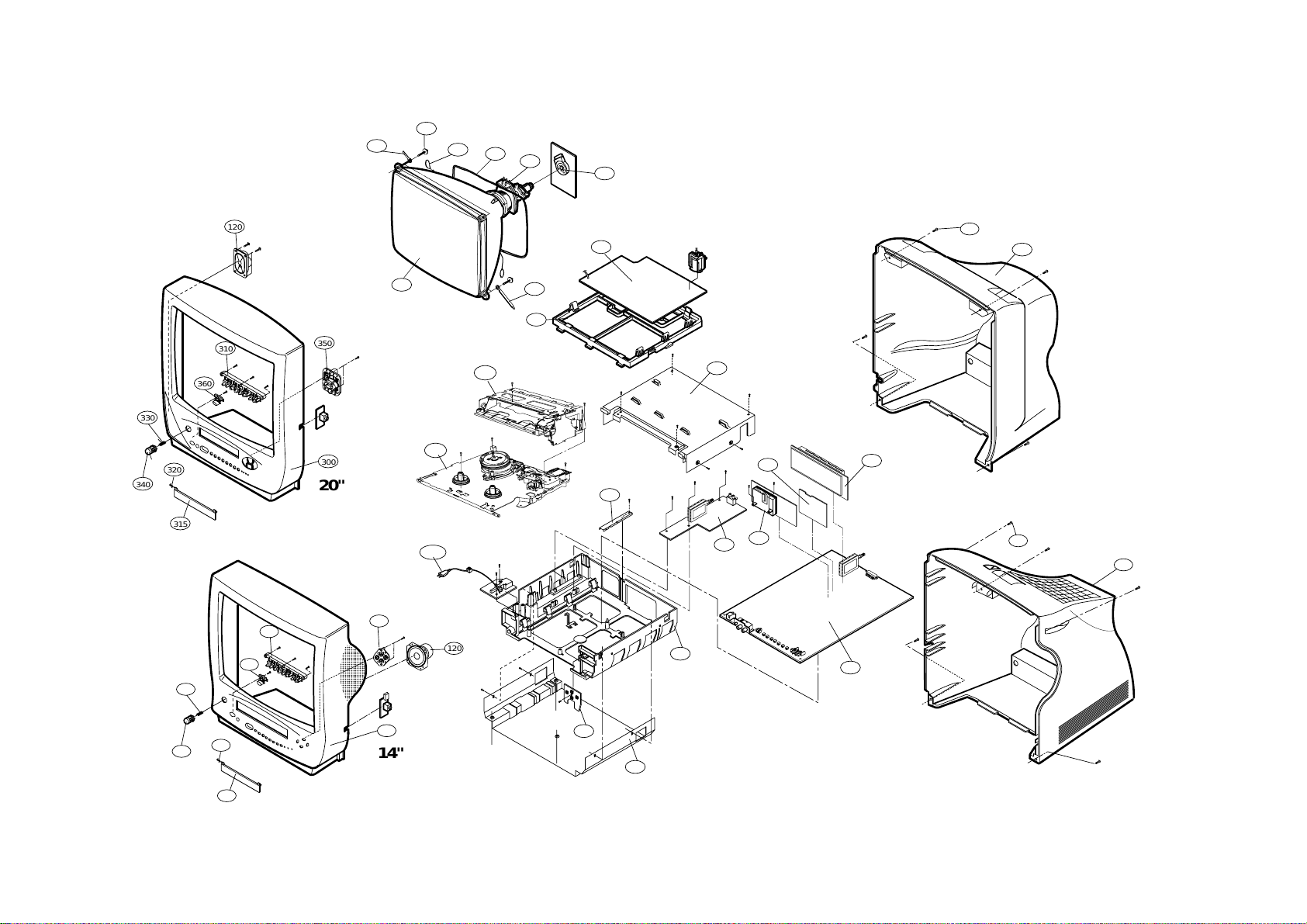

EXPLODED VIEW PART LIST The components identified by shading and

mark are critical for safety.

Replace only with part number specified.

LOCA. NO PART NO DESCRIPTIONS

102 341-721E HOLDER,D-COIL(FOR SAFA,L=65)

103 341-721F HOLDER,D-COIL(FOR SAFA,L=130)

112 2055-V1221B CPT A48QAD220X 03N7ND(+0.4) 20"

2055-V0744D CPT A34KPU02XX 31N7ND(+0.4) 14"

120 120-C93G SPEAKER,GENERAL C091P06K1459 8OHM 5/ 20"

120-101B SPEAKER,C080P17-54PK14 14"

150 150-D02M COIL,DEGAUSSING,CU 20" 60T 15OHM

150-D02B COIL,DEGAUSSING,CU 14" 42T 5.7OHM

153 153-276A DY DCAM1-20PLAA 20"

153-113V DY DCAD2-14SNAB 14"

170 170-851B LEAD SET ASSY,CPT EARTH(L=640) 20"

170-851A LEAD SET ASSY,CPT EARTH(L=460) 14"

300 3091V00057E CABINET ASSY,KI-20U72X KPLKU,LG (SILVER)

3091V00064A CABINET ASSY,KI-14U71

315 315-740H DOOR,FOR TVCR

310 5020V00118A BUTTON,CONTROL 20"

5020V00137A BUTTON,CONTROL 14"

320 4970V00001A SPRING,CST DOOR(2880)

330 320-075B SPRING,KNOB 20"

320-075R SPRING,COIL 14"

340 5020V00116A BUTTON,POWER MAIN 20"

5020V00135A BUTTON,POWER MAIN 14"

350 5020V00119A BUTTON,CH/VOL 20"

5020V00138A BUTTON,CH/VOL 14"

360 5020V00117A BUTTON,POWER SUB 20"

5020V00136A BUTTON,POWER SUB 14"

400 3809V00043E BACK COVER ASSY,KI-20U72 KPLKU

3809V00043F BACK COVER ASSY,KI-20U71 KPLKU

3809V00076E BACK COVER ASSY,KI-14U71 KPLKU

501 4810V00012A BRACKET,SMPS(27DECK)

511 6620VBC001A SOCKET,CPT 29.1 PHI SINGLE(PCS629-03A) 20"

381-100F SOCKET,CPT 022.5 S/LESS(PCS625-11) 14"

520 6871VDM027A PWB ASSY,MAIN2 PV-71A 20INCH(SMPS/CPT)

6871VDM027E PWB ASSY,MAIN2 PV-71A 20INCH(SMPS/DEF)

6871VDM027F PWB ASSY,MAIN2 PV-71A 14INCH

601 4810V00062B BRACKET,MAIN 1 ASSY SUS SPUUPRTER

602 4814V00016A SHIELD,BOTTOM

603 4814V00015A SHIELD,TOP 20"

4814V00015D SHIELD,VCR ASSY SBHG1-A 14"

604 4980V00014A SUPPORTER,YC,VCD PCB

610 6871VMM065B PWB ASSY,MAIN1, PV71A(I/I,2T,W/TXT)

6871VMM065N PWB ASSY,MAIN1, PV71A(I/I,1T,W/O TXT)

6871VMM065M PWB ASSY,MAIN1, PV71A(I/I,1T,W/TXT)

620 6871VSM094B PWB ASSY,Y/C PV71A,(W/O SECAM), M/I

630 6871VSM121B PWB ASSY,EXTRA SUB PV71A ETC (2T,B/G,I/

6871VSM121C PWB ASSY,A/V PV71A (1T,B/G,I/I)

640 6871VSM095C PWB ASSY,VCD PV71A 20" (I/I,TXT),M/I

6871VSM095F PWB ASSY,VCD PV71A 20" (I/I,W/O TXT)

6871VSM203G PWB ASSY,VCD PV71A 14" (I/I,W/O TXT)

6871VSM203A PWB ASSY,VCD/TXT 14"

650 6871VSM122B PWB ASSY,PV71A, TUNER2(I/I) ,M/I

660 6871VSM070A PWB ASSY,KEY BOARD MV-64A

913 332-057B SCREW ASSY,HEXAGON HEAD 20"

332-057A SCREW ASSY,HEXAGON HEAD 14"

943 1PPF0403116 SCREW,PAN HEAD D4 L16

A00 145-001H DECK ASSY,TV27A20P183B(6731RTV005B)

A20 146-001B HOUSING ASSY,D27S(VIDEO (219-023A))

P851 174-225E CORD ASSY,POWER UK,224A

" 174-225K CORD ASSY,POWER UK L4=100