SIAÇNARF

5

GENERAL INFORMATION

It is strictly forbidden to copy or reproduce this instruction manual without written permission to do so by LIFE home integration and will be subject to verification. Translation into other languages of all

or part of the manual is strictly forbidden without previous written authorisation from LIFE home integration and will be subject to verification. All rights on this document are reserved. LIFE home integratio

will not accept responsibility for damage or malfunctions caused by incorrect installation or improper use of products and Users are therefore recommended to read this manual carefully. LIFE home integration

will not accept responsibility for damage or malfunctions caused by the use of the operator together with the devices of other manufacturers; such action will render the warranty void LIFE home integration

will not accept responsibility for damage or injury caused by non-compliance with the installation, set up, maintenance and use indications contained in this manual and the safety instructions described

in the SAFETY INSTRUCTIONS AND WARNINGS chapter. With the aim of improving its products, LIFE home integration reserves the right to bring about alterations to them at any time, without giving

prior notice. This document conforms to the state of the automation at which it is provided when released for sale.

INFORMATION ON THE MANUFACTURER

LIFE home integration is the manufacturer of the ACER operator (and will hereinafter be referred to as manufacturer) and the owner of all rights concerning this document. The Manufacturer’s information

required by Machinery Directive 98/37/EC is given below:

• Manufacturer: LIFE home integration

• Address: Via I Maggio, 37 – 31043 FONTANELLE (TV) Italia

• Telephone: + 39 0422 809 254

• Fax: + 39 0422 809 250

• http: www.homelife.it

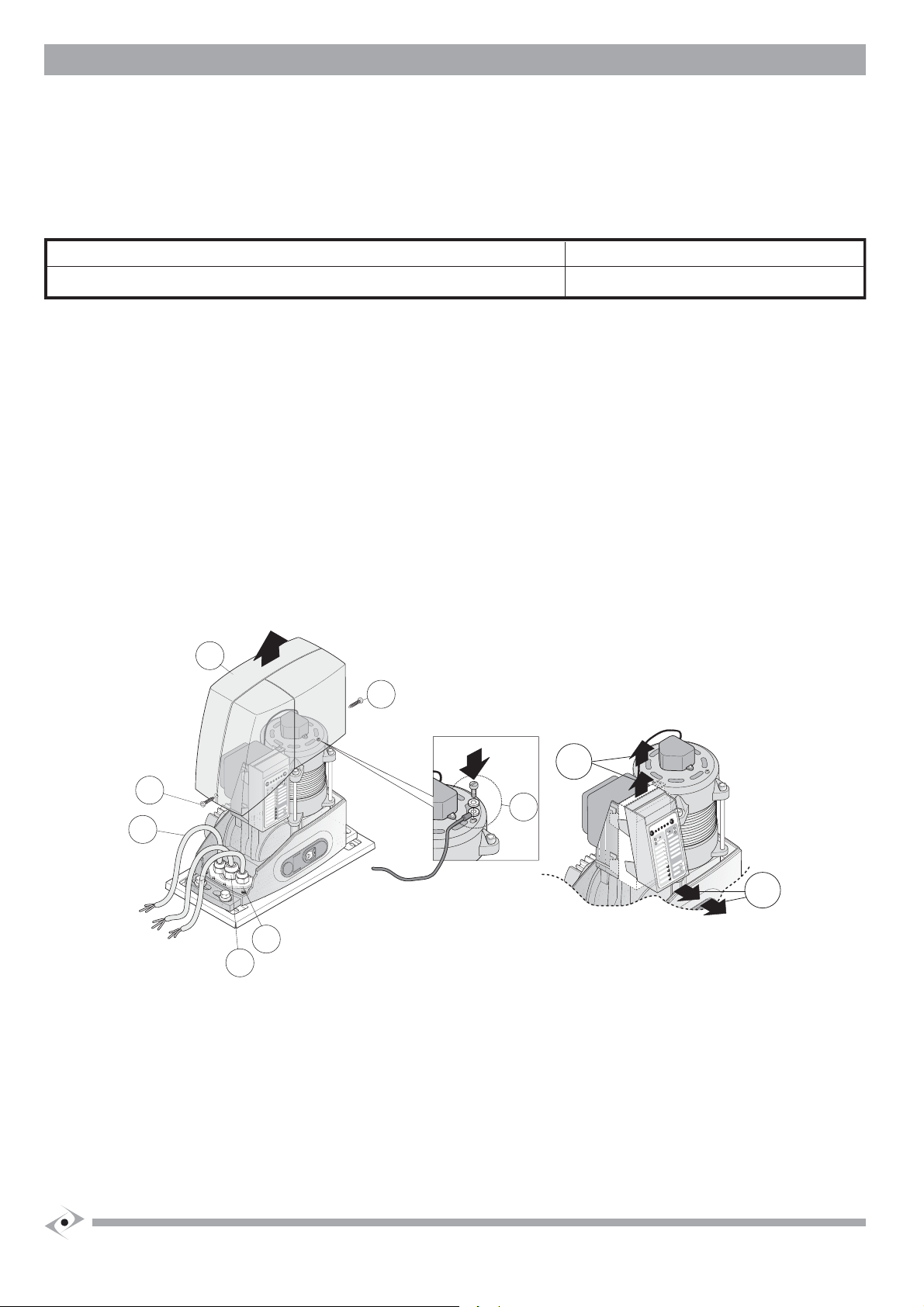

The identity plate bearing the information on the Manufacturer of the operator is fixed to the control unit. The plate specifies the type anddate (month/year) of manufacture of the automation.

For further information on technical or commercial issues and technician call-out and spares requests, Clients may contact the Manufacturer or area representative from which the product was purchased.

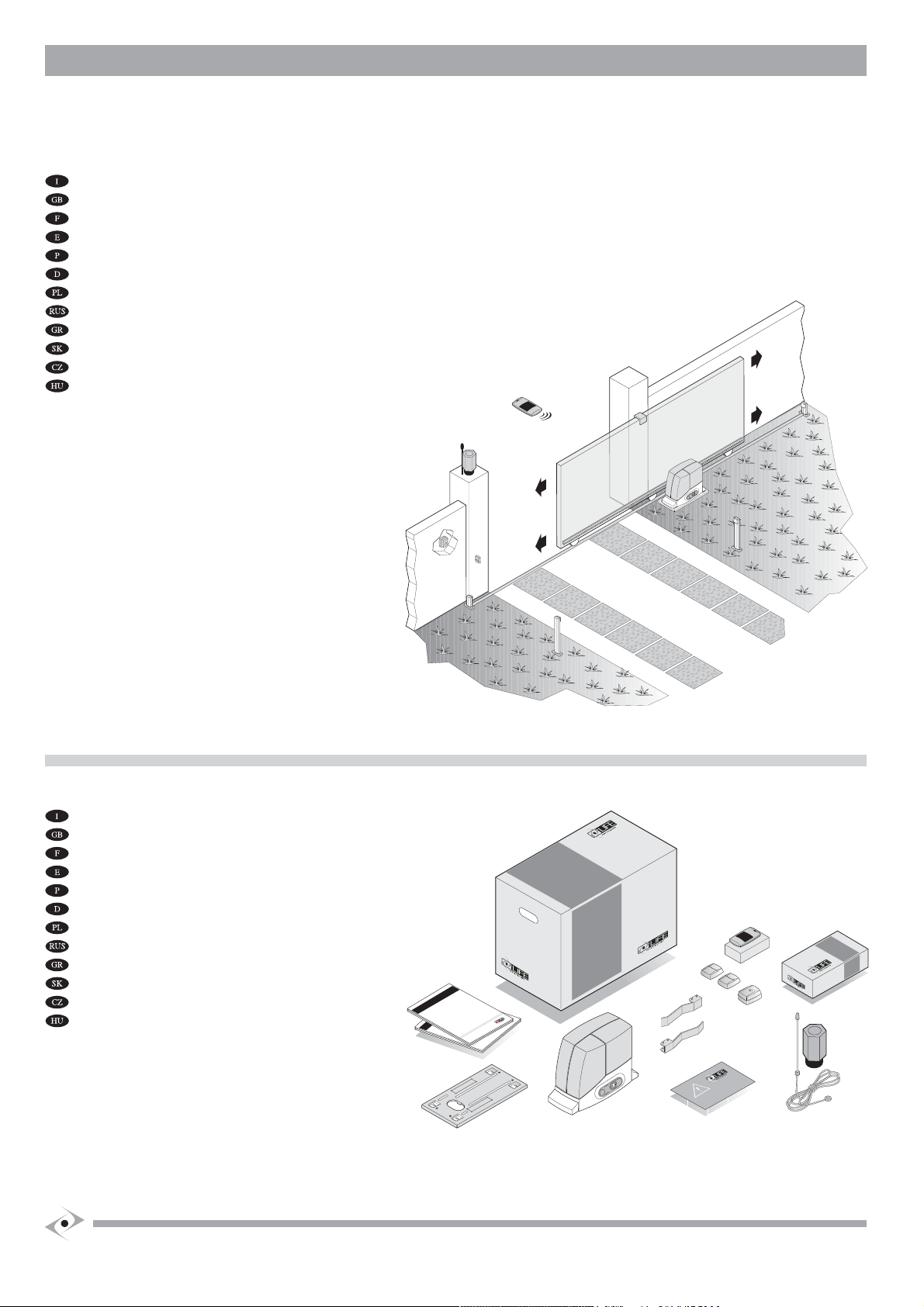

INTENDED USE

• ACER operators are designed for opening and closing residential-type sliding gates only. Improper use or use on gates larger than those indicated in the TECHNICAL DATA chapter will

be considered non-conform to the intended use. The Manufacturer declines all responsibility for improper use. The owner accepts full responsibility for improper use, which will result

in the warranty being rendered void.

• Any usage differing from that described above is forbidden.

• The operator may not be installed or used in potentially explosive environments.

• The Fitter must ensure that the environment in which the automation is installed is conform to the operator’s temperature range (see Technical Data chap.).

• The operator is not suitable for use on gates with built-in doors unless the automation is prevented from functioning when the door is open.

• Motorised gates must conform to current European standards and Directives, including EN 12604 and EN 12605.

• T

he operator may only be used when in perfect working order and in compliance with the intended use, in the awareness of safety and hazard conditions and in observance with the instructions for installation and use.

• Any dysfunctions that may pose threats to safety must be eliminated immediately.

• The gate must be stable, properly hung and resistant to flexion (it must not bend during opening and closure movements).

• The operator cannot compensate for faulty or incorrectly hung gates.

• The operator may not be used in environments prone to flooding

• Do not use the operator in environmental conditions characterised by harsh atmospheric agents (e.g. Salty air).

SAFETY INSTRUCTIONS AND WARNINGS

• These general rules must always be respected during the installation, connection, testing, trial run, use and maintenance of the automation.

• The Manufacturer declines responsibility for damage or injury caused by non-conformity with the information supplied concerning installation, trial run, use and maintenance contained

in this manual, and the failure to observe the safety instructions given below.

• The installation, connection, testing, trial run and maintenance of the operator must be performed by a COMPETENT PERSON aided and supervised by a PROFESSIONAL FITTER.

• Given the technical, procedural, regulation and legal implications of the work, unauthorised fitters are not permitted.

• Installation requires a practical and theoretical knowledge of mechanics, electronics and electrics, and of sector laws and standards.

• Amateur installation is strictly forbidden as it does not comply with current standards and laws and therefore does not guarantee the safe operation of the automation.

• Do not proceed with installation, connection and trial run in the event of doubts or indecision of any kind.

• This manual must be read carefully and understood before installing the operator. If doubts arise during installation, contact a PROFESSIONAL FITTER or the MANUFACTURER.

• Do not perform adjustments and/or parameter memorisation before installation is complete and only if you have understood the procedures described in this manual.

• O

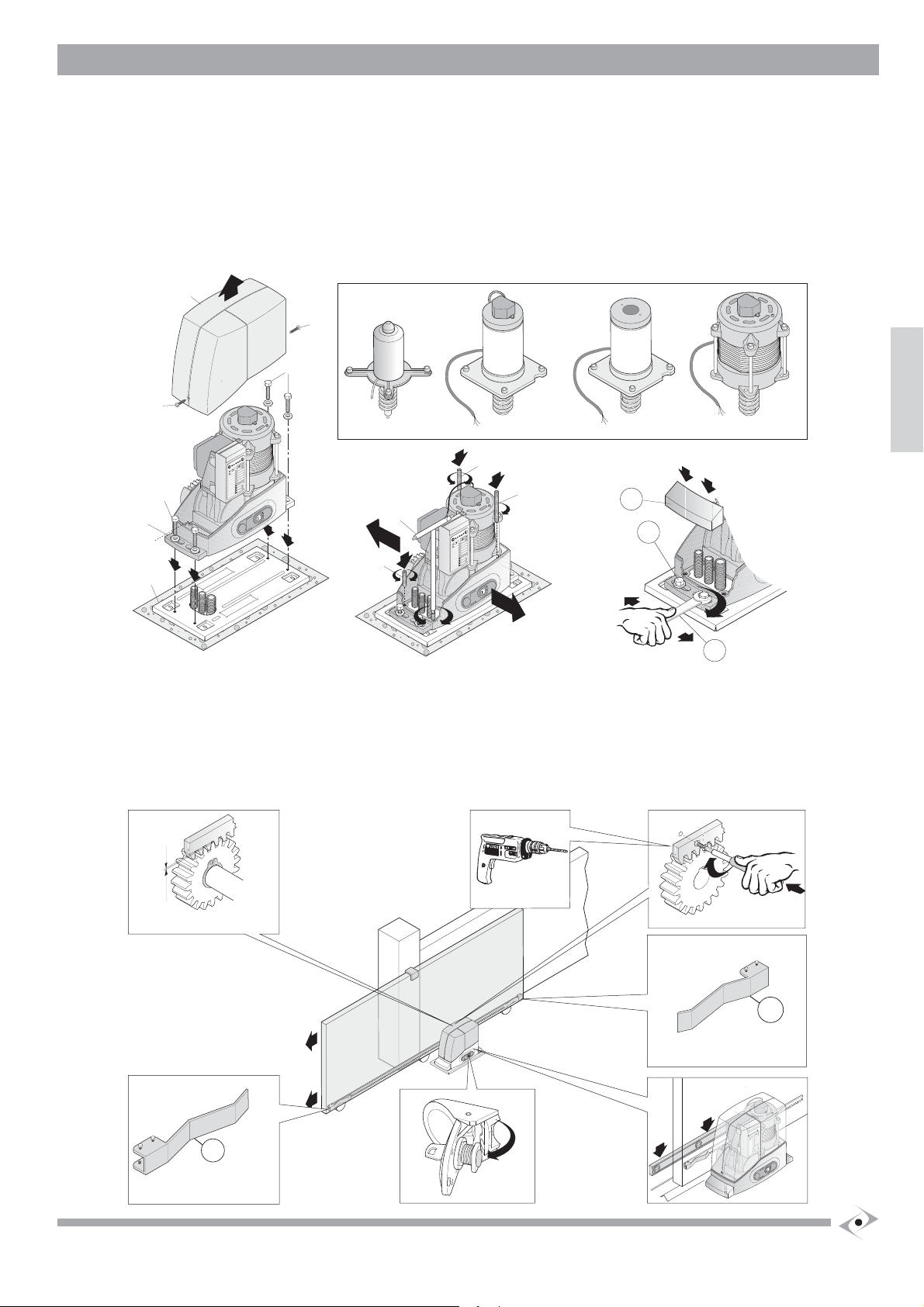

nly mount the operator on gates that are perfectly aligned with the sliding tracks and are properly hung. A gate that is not correctly aligned or hung can cause serious injury and/or damage to the operator.

• The Manufacturer declines all responsibility for damage and faults to the operator caused by non-observance of the instructions contained in this manual.

• Keep this manual in a safe and easily accessible place so that it can be consulted rapidly when necessary.

• During installation, connection, trial run and usage of the operator, observe all applicable accident prevention and safety regulations.

• In the interests of safety and optimal functioning of the operator, only use original spares, accessories, devices and fastening apparatus.

• D

o not perform alterations on any operator device or component. This type of operation may cause malfunctions. The Manufacturer declines all responsibility for damage caused by products that have been modified.

• The operator should not be used until the setting up procedure described in the STARTING UP chapter has been performed.

• S

hould liquids penetrate inside the operator, disconnect the electricity supply and contact the Manufacturer’s Assistance Service immediately; use of the operator in such conditions may cause hazard situations.

• In the case of faults or problems that cannot be resolved using the information contained in this manual, contact the Manufacturer’s assistance service.

Storage instructions and warnings

• The manufacturer declines all responsibility for damage and faults to operator functioning caused by non-compliance with the storage instructions given below.

• The operator must be stored in closed, dry places, at room temperatures of between –20 and +70°C.

• Keep the operator away from sources of heat and naked flames, which could damage it and cause malfunctions, fires or hazard situations.

• Keep the operator in a horizontal position, but not resting on the ground.

Indications and warnings for use

• It is the fitter’s duty to perform risk analysis and inform the user/owner of any existing residual risks. Any residual risk detected must be recorded in writing in this manual.

• T

he following residual risks are usually present in moving gates: impact and crushing against the main closure surface; impact and crushing in the opening area; shearing between sliding

leaf and fixed part of the track and support during movement; mechanical risks caused by movement.

• T

he Manufacturer will not accept responsibility for damage or injury caused by the non-observance of the information on use contained in this manual, and the failure to observe the safety

indications given below.

• The Manufacturer declines responsibility for damage and malfunctions caused by non-compliance with the instructions for use.

• Keep this manual in a safe, easily accessible place, so that it can be consulted rapidly when necessary.

• Never touch the gate or moving parts when they are in motion.

• Remain at a safe distance when the gate is in motion: only pass when the gate is completely open and immobile.

• Prevent children from playing or standing in the vicinity of the gate or the control organs (radio control), the same precautions should be adopted for disabled persons and animals.

• In the event of malfunctions (noisiness, jerky movements, etc.) suspend the use of the automation immediately: failure to observe this rule may entail serious hazards, risks of accidents and/or serious

damage to the gate and the automation. Contact a PROFESSIONAL FITTER and in the meantime use the gate manually by disconnecting the operator (see the OPERATOR RELEASE chapter).

• In order to maintain the operator in efficient conditions, ensure that the operations indicated in the MAINTENANCE chapter are performed at the frequency indicated by a PROFESSIONAL FITTER.

• S

hould liquids penetrate inside the operator, disconnect the power supply immediately and contact the Manufacturer’s Assistance Service; the use of the operator in such conditions may cause hazard situations.

• If a problem arises that cannot be resolved using the information contained in this manual, contact the Manufacturer’s assistance service.