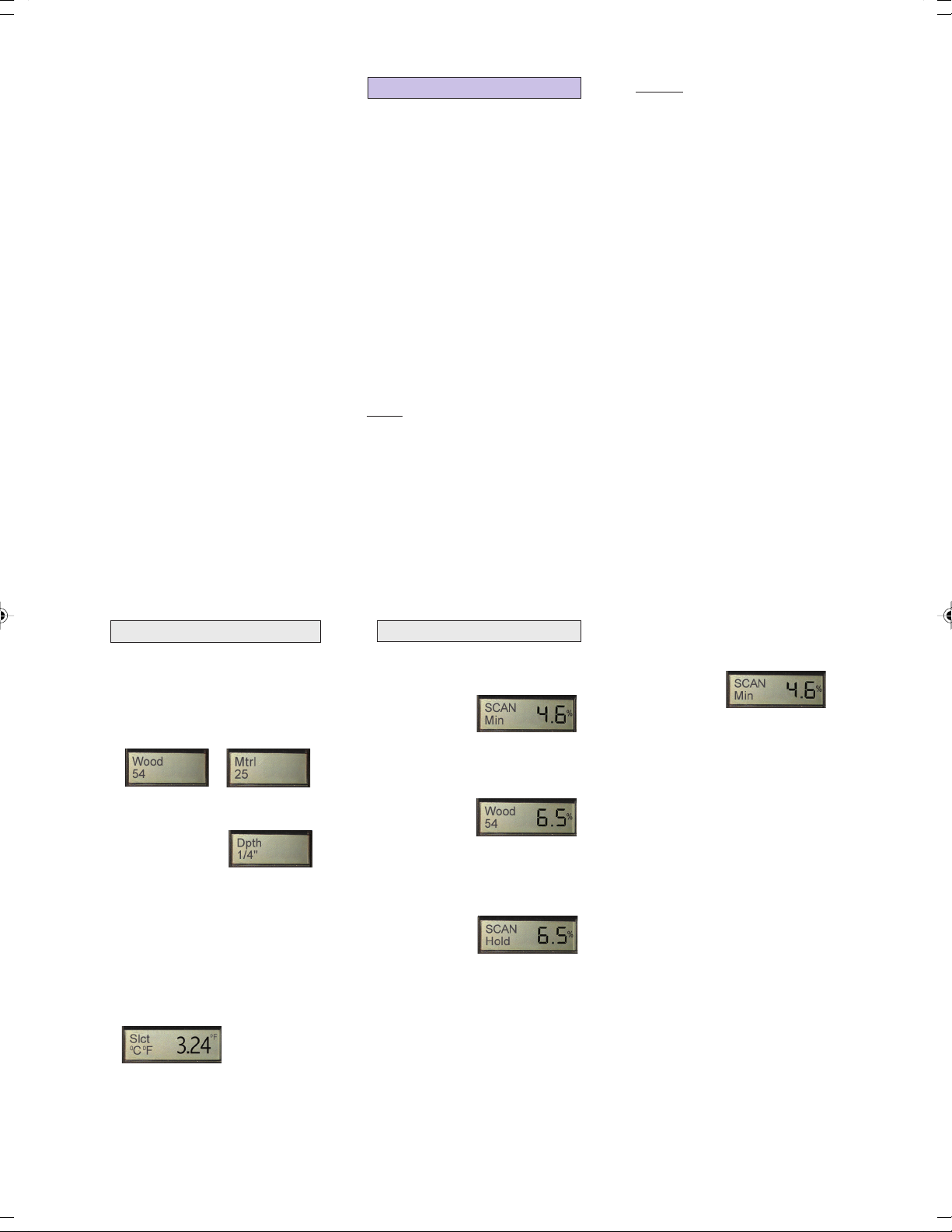

Selectable Measuring Depths

Unique to Lignomat’s meters.

Dual-depth feature allows measuring:

- All thicknesses from veneer to 1.5”.

See section B8.

- Hardwood top layer of laminates

or engineered boards and floors.

- Wood floors thinner than 3/4” with-

out including concrete or subfloor

underneath.

- Moisture close to surface and

deeper down to compare core and

surface moisture.

3/4” or 20mm

1/4” or 7mm

B6

While measuring, you can toggle be-

tween the two measuring depths.

Push the

T

key to switch to 1/4”

(20mm). Push the

S

key to switch

to 3/4” (7mm). One hand can hold

the meter, the other hand can acti-

vate the up or down key. You do not

have to move the meter at all.

A great way to compare surface with

core moisture.

The measuring depth is crucial. For

samples thinner than the measuring

depth, readings may not be accurate:

-If not enough test material is under-

neath the sensor plates, values may

be too low.

- If material underneath the test

sample is included in the measure

ments, values may be too high.

Toggle between 1/4” and 3/4”

B7

We recommend placing a light-

weight material such as Styrofoam

under the veneer. It not only pre-

vents inaccurate readings, but also

helps to create a flat measuring plat-

form for the veneer. To obtain ac-

curate readings for very thin ve-

neer it may be necessary to make

a stack of several sheets.

Veneer

If the sample to be measured is

composed of different wood spe-

cies or different materials (linoleum

glued on to wood, plywood, bam-

boo flooring with a wood core,

etc...) or if no wood species set-

ting exists a setting can be found

by using a dry sample board.

The dry sample could come from

your office or from an area that

has already dried out or from a

place where excess moisture never

reached. Estimate the moisture...

(continued section F1)

Find Settings for Composite

and Engineered Boards.

B8

content. An acclimated sample

from a home, office or show room

should be at around 7.5%.

Start by selecting setting #50.

Then take a measurement.

- If the reading is below 7.5%,

choose a setting lower than #50.

- If the reading is above 7.5%,

choose a setting higher than #50.

Then take another measurement.

Change settings, until you find a

setting, which gives a value of

7.5%. This setting can be used in

the future for the same product.

Calculating Specific Gravity

The specific gravity can be calcu-

lated, if the Weight (W) in Ounces

and the Length, Width and Heights

in inches is available:

(Weight x 1.73)

—————————

(W x L x H)

Once the specific gravity has been

found (value between 0.3 and 1.00)

the corresponding setting is be-

tween 30 and 100.

See section B2.

F1

For the Floor Installer

Moisture meters should be used

throughout the installation process.

First, when the floor is delivered, to

make sure the floor is dry.

Next, before and after acclimation,

to make sure the floor is acclimated

to the ambient conditions at the place

of installation. Best mark selected

sample boards and take readings re-

peatedly.

The moisture condition of the floor

should be documented at the time

the customer signs off on the instal-

lation. Select several moisture sensi-

tive areas. Take readings on both

depth levels and document the read-

ings with species setting, measuring

depth and location. Maybe even tak-

ing a photo to pinpoint the location.

If you ever have to go back to check

out a complaint, you can measure

the same areas again and compare

with the origina

l readings. Keeping

track of moisture conditions may in

the end protect you from unwarranted

claims.

Comparing readings taken at 1/4”

and 3/4” can also help to diagnose

problems and indicate if moisture

was absorbed from the down-side

or the up-side of the floor.

Measuring Concrete and other

Building Materials

Comparative readings can be taken

in most building materials, where

higher readings indicate more mois-

ture. These qualitative test results

can indicate problem areas. Test re-

sults from pin or pinless meters should

not be used to decide whether or not to

lay a wood floor over a concrete slab.

An RH in-depth probe test is recom-

mended. NWFA ruling. See section F5.

F2 F3

Ligno-DuoTecBW and RH new.internet.p65 10/18/2011, 4:11 PM2