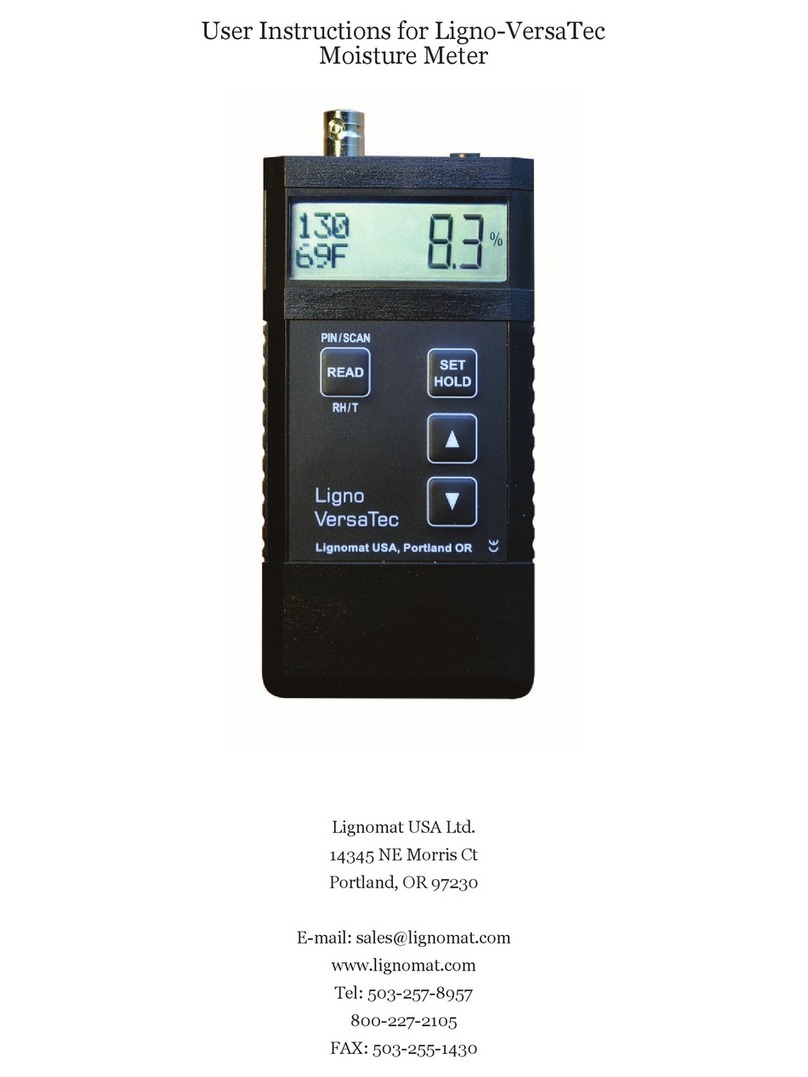

The Ligno-VersaTec functions as a resistance-type meter in pin mode. The conductivity

between the pins is measured and the moisture content is calculated according to the

active wood species and wood temperature settings. The meter indicates the highest

moisture value within the small measuring area between the tip of the teflonized pins.

Ligno-VersaTec pin measurements have to be corrected for:

(1) Wood species or other materials being measured.

(2)

Wood temperature.

-

Settings for measuring depth do not affect pin measurements.

(1) The settings for the most common wood species, bamboo products and different

building materials are listed on the laminated pocket guide included with the meter.

For unlisted species or new products call customer service at 800-227-2105. If no list-

ing is available, Lignomat offers testing to determine the correct setting.

Pin Technology and Settings

Pin mode (Unlisted code numbers do not work in pin mode) code #

Moisture measurements of individual wood species, 5-99.9% 111-230

Bamboo in pin mode within wood settings, 5-99.9% 170-180

Reference scale for laminates and composites made of wood, 0-99.9 0

Moisture measurements of sheetrock and gypsum, 0.1-22% 15

Reference scale for concrete and other similar materials, 0-99 25

Reference scale for bldg materials other than concrete or sheetrock, 0-99 10

Wood groups used in older Lignomat pin meters, 5-99.9% 1-4, 101-104

EMC measurements with Lignomat’s EMC sensor, 5-27% 5, 105

The meter will not produce values in pin mode for code numbers not listed here. Page 6.

(2)

The meter needs to be set for the correct wood temperature. Different ambient

temperatures do not affect the readings. However, measuring hot or cold lumber will

affect the readings. The Ligno-VersaTec has corrections for different wood temperatures

built-in. Once you set the meter for the wood temperature and for the wood species, the

corrected moisture value is displayed. Temperature adjustments are not necessary if the

meter is set for a wood temperature of 700F and the lumber is within 55-850F.

It is difficult to actually measure the wood temperature at the depth, where the tips of

the electrode pins are measuring. If the wood has been acclimated to the ambient (air)

temperature, choose the ambient temperature. If the wood is not acclimated, choose the

average temperature over the last few hours.

Pin Mode

7