Subject index

1

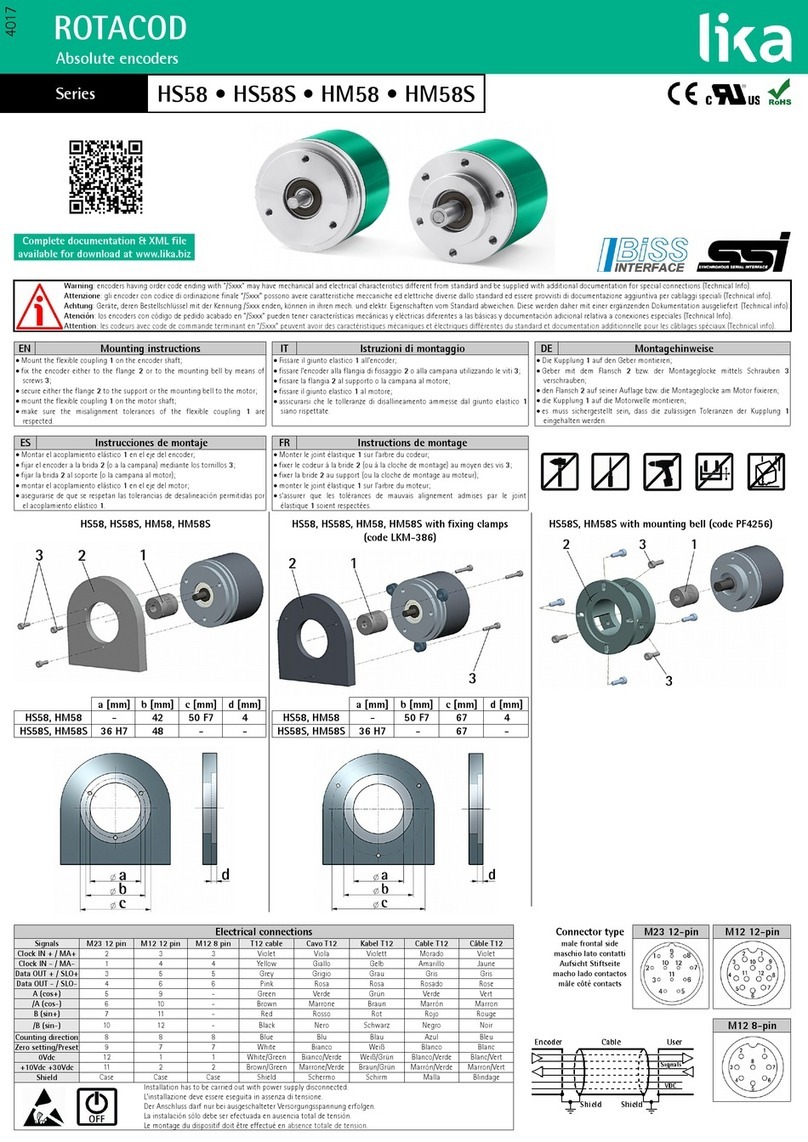

1000-00 Device type......................................................47

1001-00 Error register...................................................47

1003 Pre-defined error field.......................................47

1005-00 COB_ID SYNC message...............................48

1008-00 Manufacturer device name......................48

1009-00 Manufacturer hardware version............48

100A-00 Manufacturer software version.............48

100C-00 Guard time.......................................................48

100D-00 Life time factor..............................................48

1010-01 Store parameters..........................................49

1011-01 Restore default parameters......................49

1014-00 COB-ID EMCY.................................................50

1015-00 Inhibit time EMCY.........................................50

1018 Identity object.......................................................50

1800 PDO1 parameters.................................................50

1801 PDO2 parameters.................................................52

1802 PDO3 parameters.................................................53

1A00-01 TPDO1 mapping parameter......................55

1A01-01 TPDO2 mapping parameter......................55

1A02-01 TPDO3 mapping parameter......................55

2

2104-00 Limit switch min............................................56

2105-00 Limit switch max...........................................56

2200-01 Code Type (BIN/GRAY)................................56

2200-02 SSI Protocol.....................................................57

2200-03 Number of SSI clocks..................................57

2200-04 Physical Singleturn Resolution [bits]....58

2200-05 Physical Multiturn Resolution [bits].....59

2200-06 Bypass................................................................60

3

3000-00 Baud rate..........................................................60

3001-00 Node-ID.............................................................60

6

6000-00 Operating parameters.................................61

6001-00 Programmable pulse per revolution.....63

6002-00 Programmable total measuring range 65

6003-00 Preset value.....................................................67

6004-00 Position value.................................................69

6008-00 High precision position value..................69

6200-00 Cyclic timer......................................................70

6500-00 Operating status............................................70

6501-00 Singleturn resolution..................................72

6502-00 Number of distinguishable revolutions

.............................................................................................72

6504-00 Supported alarms.........................................73

6506-00 Supported warnings....................................73

6507-00 Profile and software version....................74

6508-00 Operating time...............................................74

6509-00 Offset value.....................................................74

650A-01 Module identification.................................74

650B-00 Serial number.................................................74

C

COB-ID of PDO1...............................................................50

COB-ID of the PDO2.......................................................52

COB-ID of the PDO3.......................................................53

Code sequence...........................................................61, 71

Current operating state.................................................71

F

Flash memory error.........................................................77

I

Initialization.......................................................................41

L

Last error occurred..........................................................47

Limit switch max.......................................................63, 71

Limit switch min.......................................................63, 71

Node guarding error.......................................................77

Number of occurred errors..........................................47

O

Operational.........................................................................41

P

Physical Multiturn Resolution....................................59

Pre-operational.................................................................41

Previous errors occurred...............................................47

Product code......................................................................50

R

Revision number...............................................................50

S

Scaling..................................................................................71

Scaling function control...............................................62

Stopped................................................................................41

T

Transmission type........................................51 e seg., 54

V

Vendor-ID............................................................................50