CONTENTS

CONTENTS ........................................................................................................................... 4

GENERAL ............................................................................................................................. 5

TRANSPORT ...........................................................................................................................................5

STORAGE...............................................................................................................................................5

MOUNTING .............................................................................................................................................5

HELP PROTECT OUR ENVIRONMENT ............................................................................... 6

DISPOSAL OF THE PACKING MATERIAL......................................................................................................6

DISPOSAL OF YOUR OLD MACHINE ...........................................................................................................6

WARNINGS........................................................................................................................... 6

GENERAL ............................................................................................................................................6

WARNINGS........................................................................................................................... 7

GENERAL...............................................................................................................................................7

DANGER ZONES......................................................................................................................................8

COMMISSIONING................................................................................................................. 9

ELECTRICAL CONNECTION.......................................................................................................................9

COMPRESSED AIR CONNECTION ..............................................................................................................9

OPERATION ....................................................................................................................... 10

CONTROL IDENTIFICATION.....................................................................................................................10

FUME REMOVAL....................................................................................................................................10

CONTROL IDENTIFICATIONR2 ...............................................................................................................11

COVERS...............................................................................................................................................12

TEST RUN ............................................................................................................................................12

HOSE CUTTING .....................................................................................................................................13

IF THE MACHINE DOES NOT WORK... .......................................................................................................13

MAINTENANCE .................................................................................................................. 13

TIGHTENING OF VBELTS .......................................................................................................................14

BLADE CHANGE ....................................................................................................................................14

BLADE ADJUSTMENT .............................................................................................................................14

OIL ......................................................................................................................................................14

CLEANING ............................................................................................................................................14

GUARANTEE ...................................................................................................................... 15

TECHNICAL DATA OF CM75 FUME EXTRACTOR........................................................... 15

TECHNICAL DATA ............................................................................................................. 16

GENERAL

CM75 PH is a universal hose cutting machine with capacity to cut all types and sizes of hydraulic hoses up

to 2” diameter multiwire hoses. The hose is fed and measured manually. It is cut by pressing it against the

rotating cutter blade. The counter facilitates working in long series.

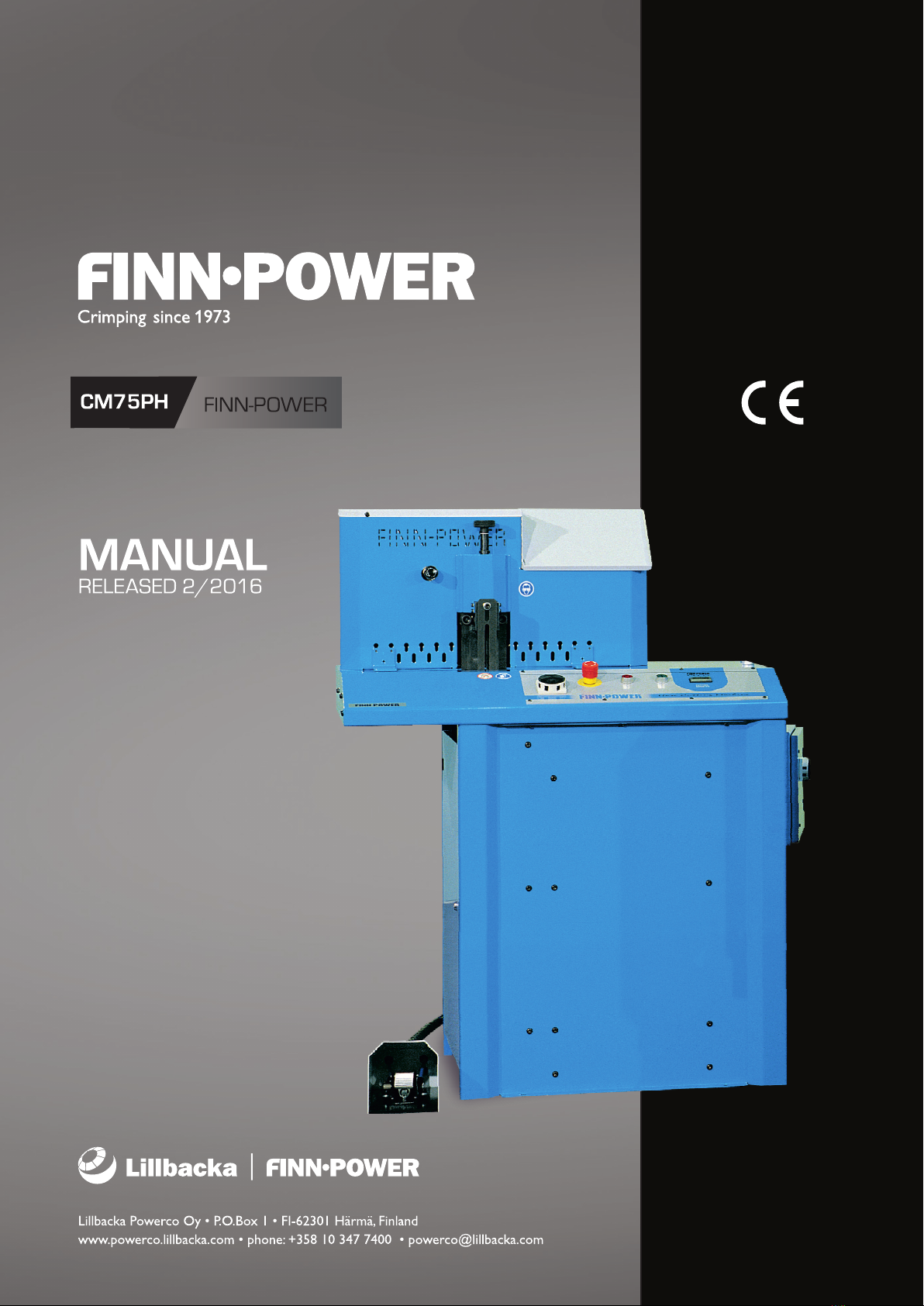

Transport

The packed machine is transported on a pallet, which is

easy to move and lift by a fork-lift truck. After unpacking,

the machine can be lifted using a hoisting belt.

Size of package: x = 97, y = 107, z = 178 cm.

Storage

The manufacturer has protected the machine against corrosion by using the Zerust method. The machined

parts have been treated with Perigol 100 protective agent. A Zerust vapor capsule has been put into the

electric box, and the machine has been packed into a bag made of Zerust film.

The protection is effective for months if the package is not opened. After opening it, the protection of the

wrapping film ceases. If the machine is not yet brought into use, it must be reprotected against corrosion. The

machine is to be stored in dry indoor conditions. Storage temperature above 0°C.

Remove the protective agent according to the instructions enclosed in the package.

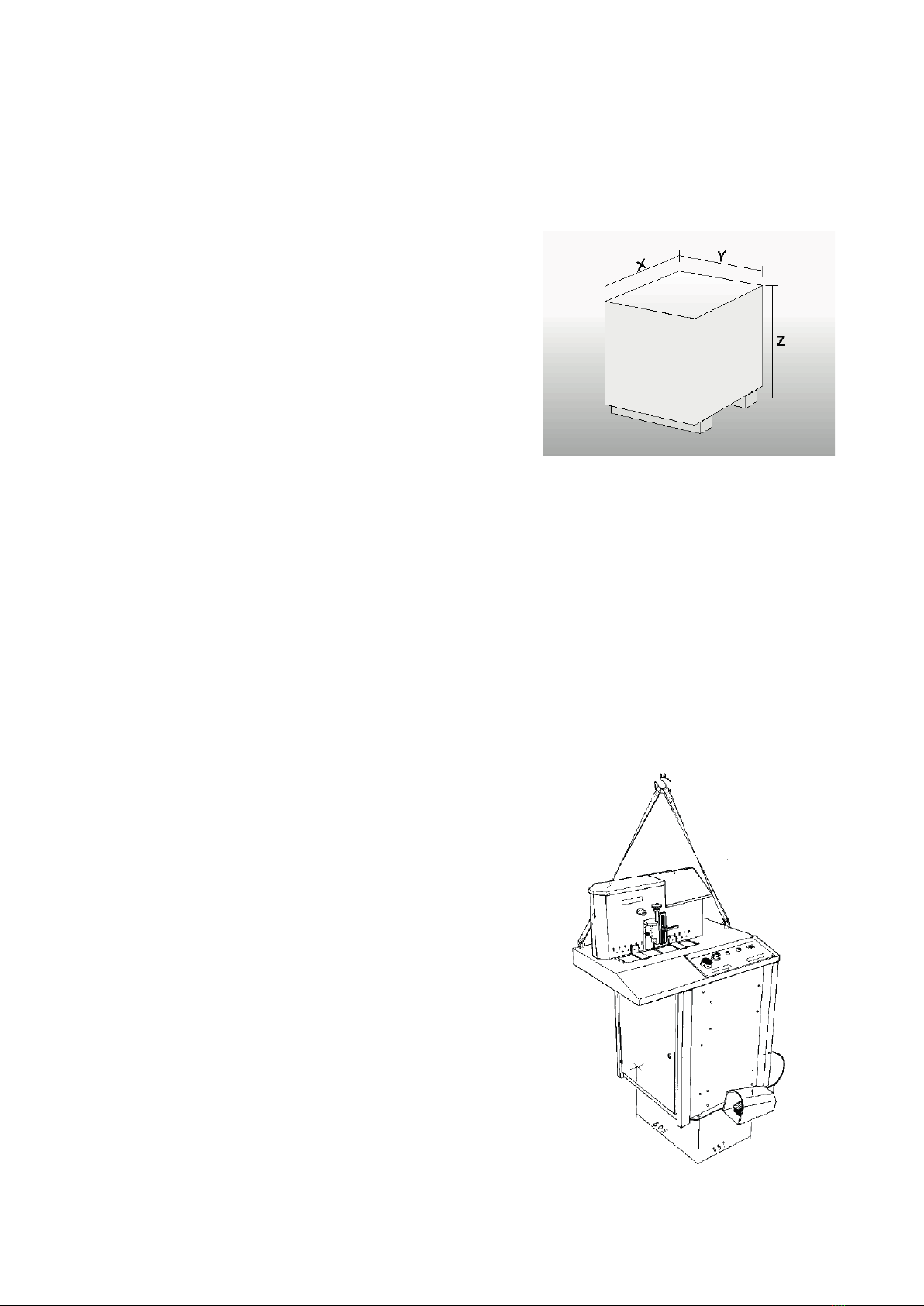

Mounting

The adjacent picture shows an appropriate way to lift

the machine after it has been unpacked.

Mount the machine on an even floor level, which is

steady enough to carry the weight of the machine,

approx. 300 kg.

It is recommended to screw the machine on the floor

with four M12 wedge anchors. Boreholes in the floor: Ø

12 mm, depth 55 mm.