8695 6650

POSIMATIC PS30 I

TABLE OF CONTENTS

A - IDENTIFICATION .........................................................................................................................1

B - SAFETY INSTRUCTIONS............................................................................................................2

1 - AIRBORNE NOISE .............................................................................................................2

2 - SPECIFIC SAFETY INSTRUCTIONS.................................................................................2

3 - IMPORTANT RECOMMENDATIONS.................................................................................3

C - DESCRIPTION .............................................................................................................................4

1 - DESCRIPTION....................................................................................................................4

2 - DETAILED DESCRIPTION.................................................................................................8

D - ASSEMBLY - INSTALLATION ....................................................................................................14

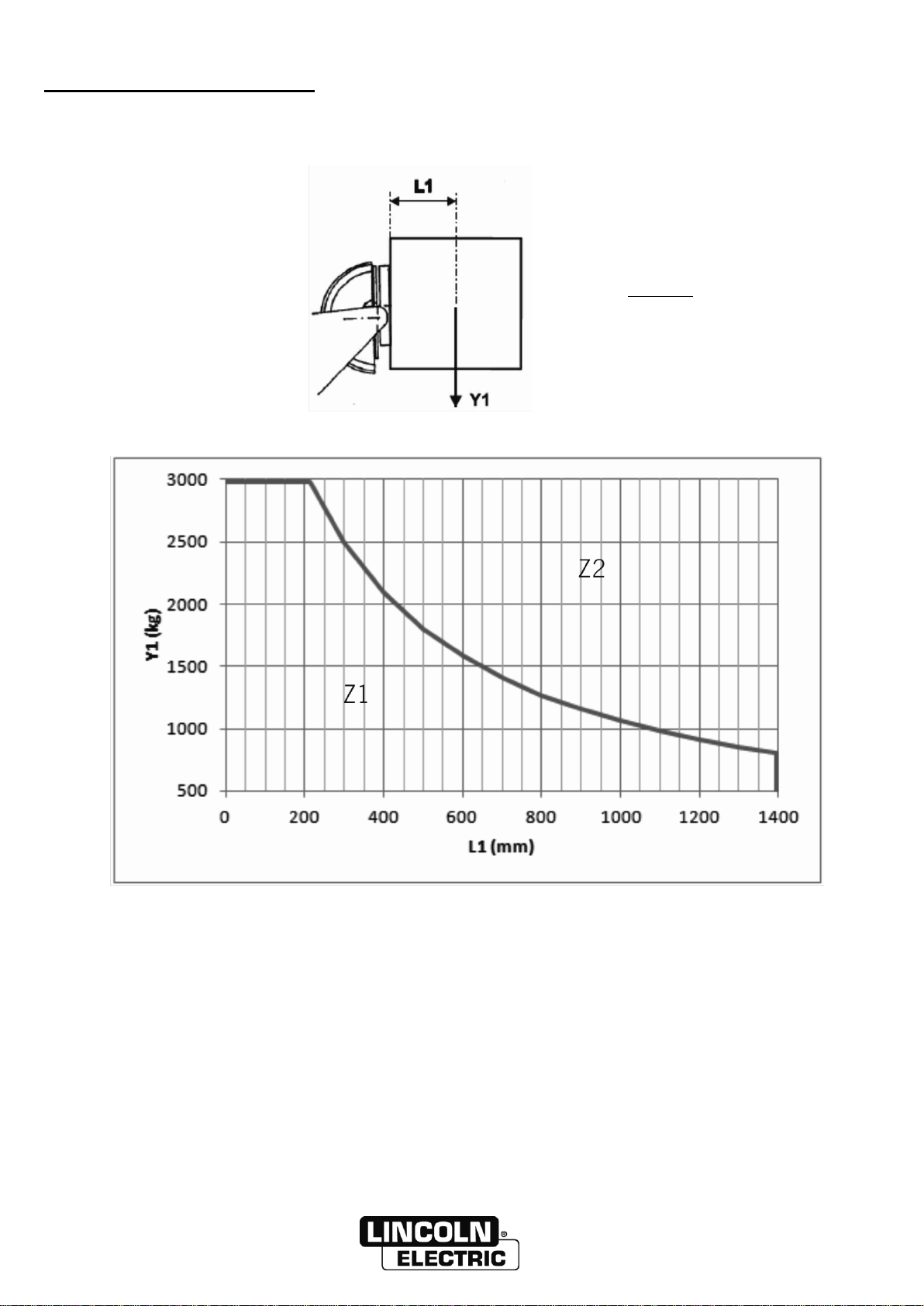

1 - HANDLING THE POSIMATIC.............................................................................................14

2 - PUTTING IN PLACE...........................................................................................................15

3 - FIXING THE POSIMATIC....................................................................................................15

4 - ELECTRICAL CONNECTIONS ..........................................................................................15

5 - INSTALLATION...................................................................................................................17

E - OPERATOR MANUAL.................................................................................................................18

1 - CONTROL BUTTONS ON CABINET .................................................................................18

F - MAINTENANCE............................................................................................................................20

1 - SERVICING.........................................................................................................................20

2 - TROUBLESHOOTING........................................................................................................25

3 - SPARE PARTS...................................................................................................................29

PERSONAL NOTES ..........................................................................................................................34