Lincoln Electric Invertec V275-S User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric POWERTEC i320C STANDARD User manual

Lincoln Electric

Lincoln Electric POWER WAVE S350 User manual

Lincoln Electric

Lincoln Electric COOARC 21 User manual

Lincoln Electric

Lincoln Electric PF42 User manual

Lincoln Electric

Lincoln Electric DC-655 IM602-A User manual

Lincoln Electric

Lincoln Electric Invertec V305-T AC User manual

Lincoln Electric

Lincoln Electric WF24 User manual

Lincoln Electric

Lincoln Electric Flextec 500X User manual

Lincoln Electric

Lincoln Electric COMMANDER 300 IM700-D User manual

Lincoln Electric

Lincoln Electric 11298 User manual

Lincoln Electric

Lincoln Electric POWER WAVE F355I User manual

Lincoln Electric

Lincoln Electric AIR VANTAGE 500 User manual

Lincoln Electric

Lincoln Electric Idealarc DC-1500 User manual

Lincoln Electric

Lincoln Electric COMMANDER SVM153-A User manual

Lincoln Electric

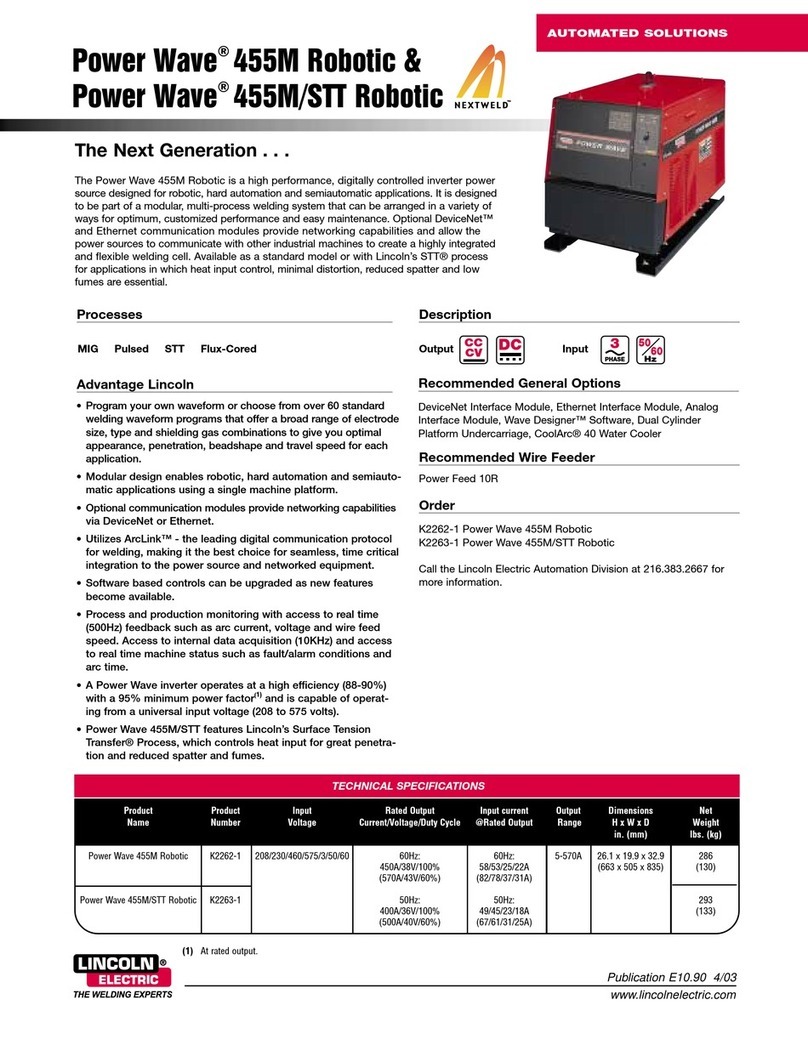

Lincoln Electric Power Wave 455M/STT Robotic User manual

Lincoln Electric

Lincoln Electric LTW1 User manual

Lincoln Electric

Lincoln Electric CRUISER K2607-1 User manual

Lincoln Electric

Lincoln Electric POWER WAVE 655/R User manual

Lincoln Electric

Lincoln Electric POWER MIG 11521 User manual

Lincoln Electric

Lincoln Electric OPTIMARC CV/CC 500 User manual