6

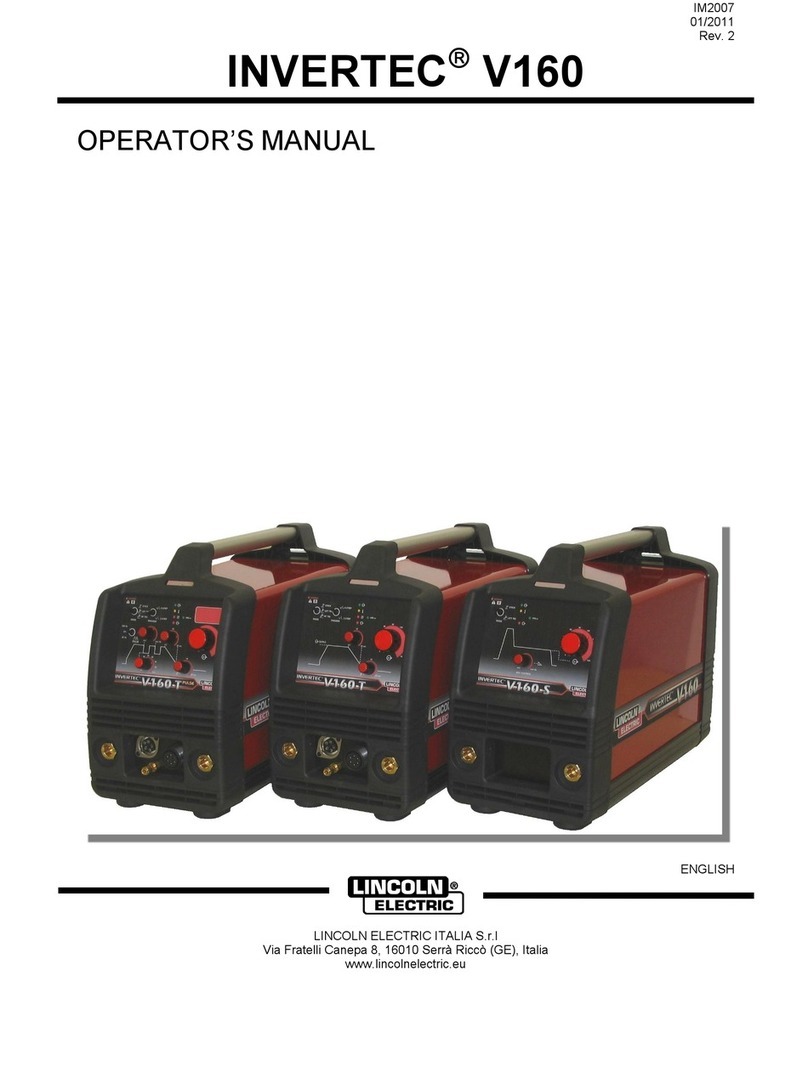

to indicate the machine is ready to weld.

2. Thermal Overload Indicator: This lamp will light up

when the machine is overheated and the output has

been turned off. This can occur if the ambient

temperature is above 40°C or the duty cycle of the

machine has been exceeded. Leave the machine

on to allow the internal components to cool, when

the lamp turns off normal operation is possible.

•Thermostatic fan: the fan is additionally

controlled by the thermal protection circuit.

This feature saves energy and also minimizes

the amount of dirt and other air borne particles

being drawn into the machine.

The fan is operating only while cooling is

needed.

3. Power on/off Switch: Controls the input power to

the machine.

4. Hot Start Control (LINC 405-SA only): Hot Start is a

temporary increase in the output current during the

start of stick (MMA) welding that helps ignite the arc

quickly and reliably. The potentiometer is used to

set the level of the increased current.

5. Negative Quick Disconnect: Negative output

connector for the welding circuit.

6. Digital Welding Current Meter with memory feature

(LINC 405-SA only): Shows present the value of

the welding current during welding; after welding it

continues to display the average welding current.

7. Output Current Control: Potentiometer used to set

the output current (also during welding), from 15A to

400A.

8. Local/Remote Switch: Remote Control Unit

K10095-1-15M and K870 can be used with this

machine. It changes control of the Output Current

from the machine Output Control (point 7) to the

K10095-1-15M or K870 and vice versa.

9. Arc Force Control (LINC 405-SA only): It is a

function used during stick (MMA) welding in which

the output current is temporarily increased to clear

short circuit connections between the electrode and

the weld puddle that occur during normal welding.

10. Remote Control Connection: If a remote control is

used, it will be connected to the remote connector.

11. Positive Quick Disconnect: Positive output

connector for the welding circuit.

12. Fuse: This fuse protects the Fan Circuit.

13. Power Input Socket: Connect the supply plug to the

existing input cable, that is rated for the machine as

indicated in this manual, and conforms to all

applicable standards. This connection shall be

performed only by a qualified person.

Stick Welding (MMA)

For starting welding process with MMA method you

should:

•Insert welding cable plugs into output sockets and

twist to lock them in place.

•Connect the work cable to the welding piece with the

work clamp.

•Fasten a correct coated electrode into the electrode

holder.

•Connect the main plug to the outlet mains socket.

•Set the Local/Remote Switch in required position:

local or remote.

•Turn the Power on/off Switch on.

•Set required welding current by knob of the Output

Current Control.

•Obeying appropriate rules you can begin to weld.

Electromagnetic Compatibility (EMC)

02/02

This machine has been designed in accordance with all relative directives and norms. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

•Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the