Soyer BMS-9 ACCU User manual

Other manuals for BMS-9 ACCU

3

This manual suits for next models

1

Table of contents

Other Soyer Welding System manuals

Soyer

Soyer PH-9 SRM12 User manual

Soyer

Soyer BMK-8i User manual

Soyer

Soyer BMK-12 W User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

Soyer BMK-12i User manual

Soyer

Soyer BMH-22i User manual

Soyer

Soyer BMK-16i User manual

Soyer

Soyer BMK-8i User manual

Soyer

Soyer BMK-8 U User manual

Soyer

Soyer BMK-16i User manual

Soyer

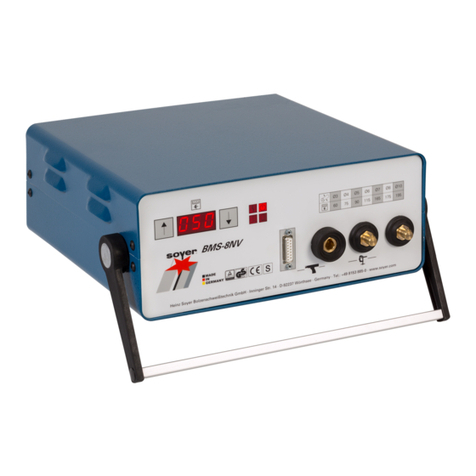

Soyer BMS-8N User manual

Soyer

Soyer BMK-12 W User manual

Soyer

Soyer BMS-4 ACCU-DUO User manual

Soyer

Soyer UVR-300 User manual

Soyer

Soyer BMK-10i User manual

Soyer

Soyer SRM EcoWeld BMK-20i User manual

Soyer

Soyer BMH-30i User manual

Soyer

Soyer BMS-9 ACCU User manual

Soyer

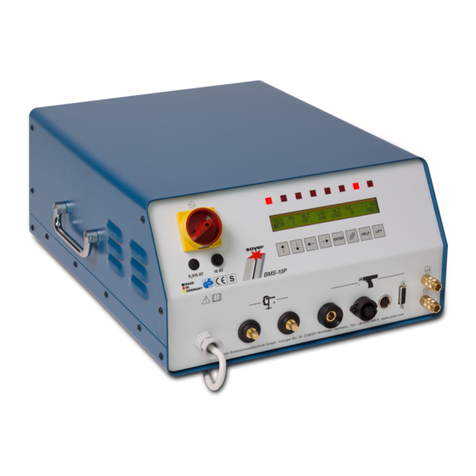

Soyer BMK-16 W User manual

Soyer

Soyer BMS-8N User manual

Popular Welding System manuals by other brands

Forney

Forney 210 MIG owner's manual

ESAB

ESAB Heliarc 283i AC/DC instruction manual

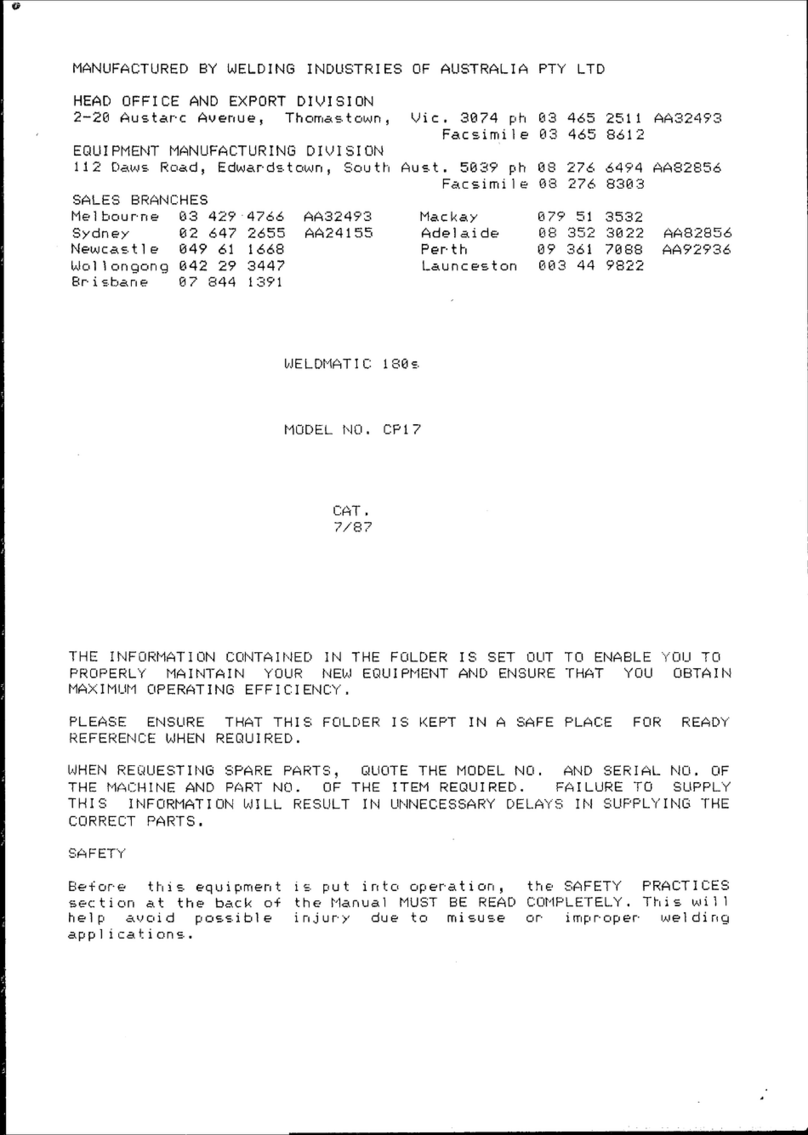

WIA

WIA Weldmatic 180s CP17 manual

Renegade

Renegade RIMIG205I instruction manual

Lincoln Electric

Lincoln Electric INVERTEC V160 Operator's manual

Chicago Electric

Chicago Electric MIG-100 91124 Assembly and operating instructions

Rothenberger

Rothenberger ROWELD ROFUSE Sani 160 Instructions for use

Demtech

Demtech Pro-Wedge 3XL Operator's manual

Parkside

Parkside PESG 120 A1 Assembly, operating and safety instructions

iWeld

iWeld HD 220 LT DIGITAL PULSE user manual

Walter

Walter Surfox 203 user guide

Air Liquide

Air Liquide CEMONT SHARP 10 Safety instruction for use and maintenance

Kemppi

Kemppi Kempact MIG 2530 operating manual

Miller Electric

Miller Electric GB-10 owner's manual

Kemppi

Kemppi KEMPOMAT 161 operating instructions

Chicago Electric

Chicago Electric 68887 Owners manual & safety manual

FRIATEC

FRIATEC FRIAMAT PRIME ECO operating instructions

Chicago Electric

Chicago Electric 68888 Owner's manual & safety instructions