7

336 804 3001.0704

Table of contents Description

Page PagePage

Foreword......................................................................... 2

Approved applications ........................................................ 2

Technical note ..................................................................... 3

Tr ck takeover ..................................................................... 3

Description ..................................................................... 5

Type plate ............................................................................ 5

Technical data ................................................................... 10

Noise emissions levels ..................................................... 12

Freq ency characteristic for h man body vibrations ......12

Technical description ........................................................ 13

Drive ...............................................................................13

Steering..........................................................................13

Hydra lic system ........................................................... 13

Operation ....................................................................... 13

Brakes ............................................................................ 13

Handbrake ..................................................................... 13

Br sh monitor................................................................. 13

Electrical system ............................................................ 13

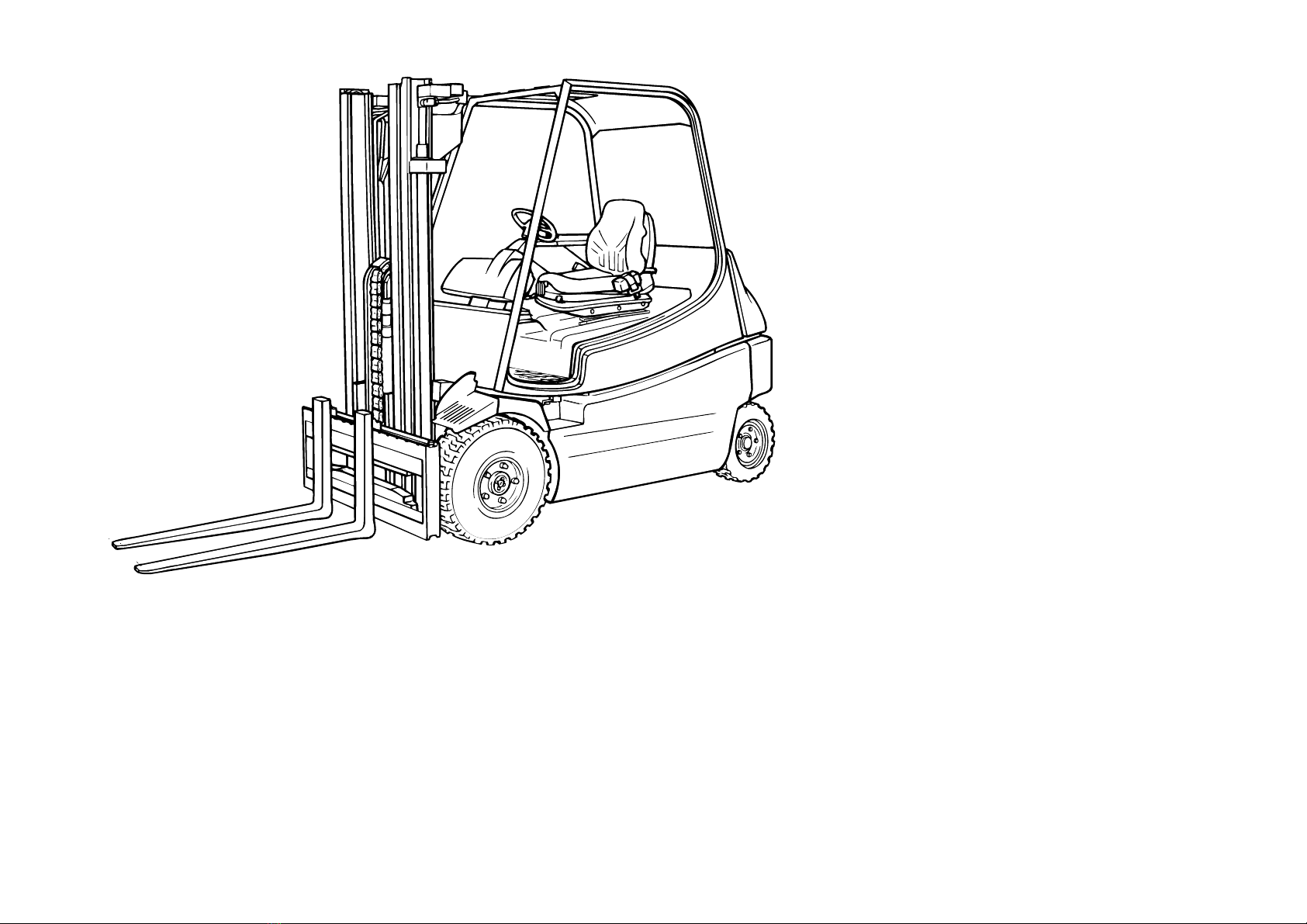

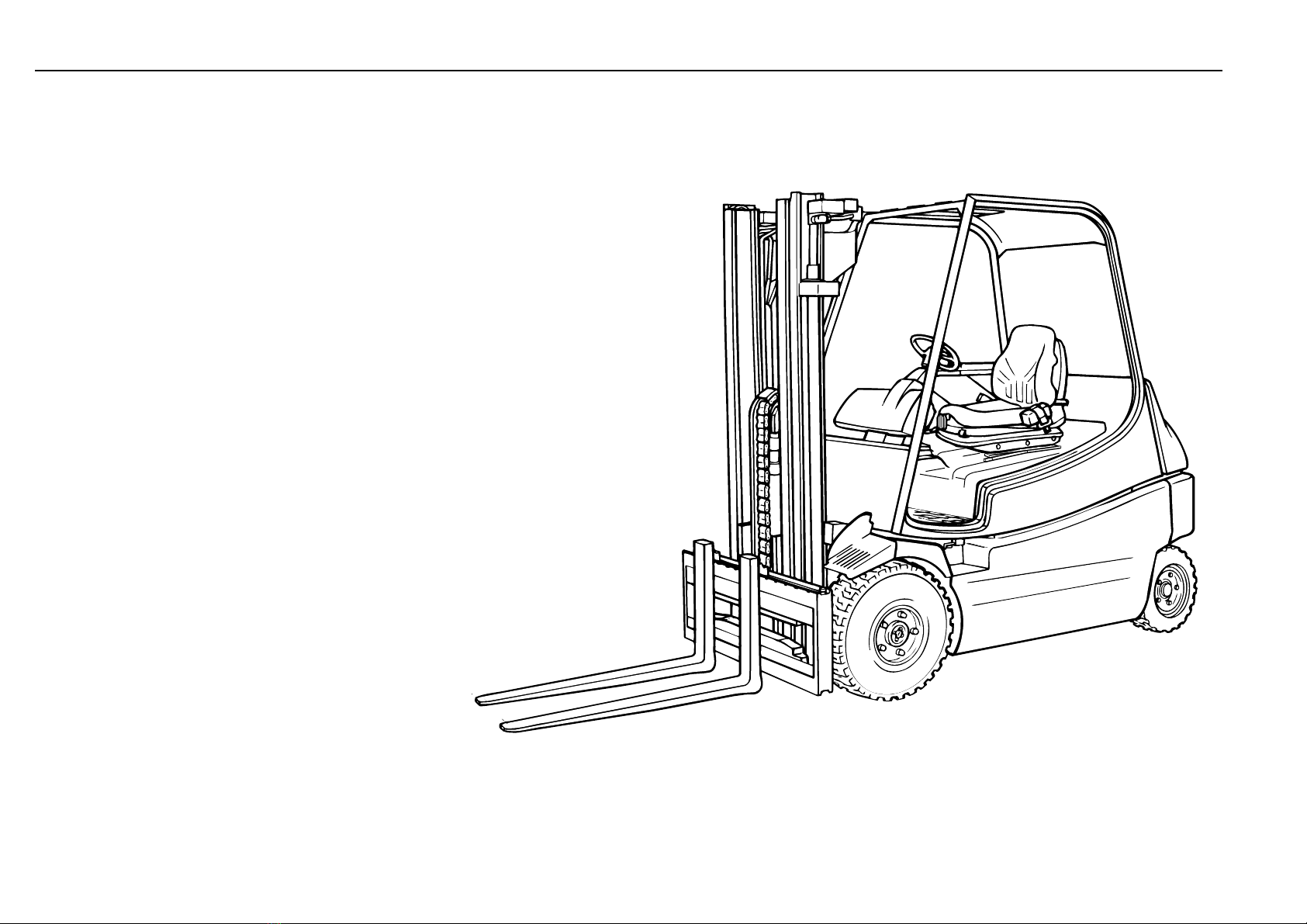

General view of tr ck ....................................................... 14

Controls and indicators .....................................................15

Composite instr ment .......................................................16

Ho r meter ..................................................................... 17

Battery discharge indicator............................................ 17

Before operation ........................................................ 18

Safety r les ........................................................................18

Safety information .............................................................18

Handling fl ids and l bricants.......................................... 18

Accident prevention check................................................ 19

Operation of ind strial tr cks in the plant area ................ 19

R nning-in instr ctions ..................................................... 19

Checks and services prior to initial operation of the

tr ck ................................................................................ 19

Daily checks ...................................................................... 19

Daily checks and servicing before operation .................. 21

Check the tyre inflation press re ...................................... 21

Check the tightness of the wheel n ts.............................. 21

Opening the overhead g ard ........................................... 22

First lock-in position: Servicing position ....................... 22

Second lock-in position: Battery change ...................... 22

Closing the overhead g ard ............................................. 23

Check the battery charge ..................................................24

Charging the battery ......................................................... 24

Connecting the battery to a s itable external charger ....25

Check the condition, electrolyte level and specific

gravity of the battery ......................................................25

Battery change .................................................................. 26

Battery removal with a crane .........................................26

Adj sting the driver’s seat ................................................27

Adj sting the swivel seat ..................................................27

Adj sting armrest of the driver’s seat ...............................27

Applying the seat belt, opening the seat belt ...................28

P sh, p ll the emergency stop b tton .............................. 29

Operation ...................................................................... 30

Driving ...............................................................................30

Travel in the forward direction ......................................30

Travel in the reverse direction ......................................30

Reversing direction .......................................................31

Reversing the direction of travel ................................... 31

Malf nctions d ring operation ......................................31

Singel-pedal model .......................................................... 32

Steering system .................................................................34

Steering..........................................................................34

Braking system .................................................................. 35

Service brake, regenerative brake................................ 35

Foot brake ...................................................................... 35

Operating the electric motor brake (LBC) ..................... 35

Handbrake ..................................................................... 35

Engaging the handbrake............................................... 35

Releasing the handbrake .............................................. 35

Central control lever (joystick) operation of mast

and attachments ............................................................ 36

Tilting the mast forward ................................................. 36

Tilting the mast back ...................................................... 36

Raising the fork carriage ............................................... 36

Lowering the fork carriage ............................................36

Operating the attachments ............................................ 36

Operating the sideshift ..................................................36

Operating the clamp ...................................................... 36

Single control lever operation of mast and attachments .37

T rning on the front working lights ...................................38

T rning on the rear working lights ....................................38

T rning on the front windscreen wiper and washer ........38

T rning on the rear windscreen wiper ............................. 38

T rning on the lighting ...................................................... 38

T rning on the hazard warning light ................................ 38

T rning on the directional indicator lights........................38

Electric heater ................................................................... 39

Tr ck Data Management (LFM) ........................................ 40

Tr ck data acq isition ................................................... 40

Condition code .............................................................. 40

Tr ck data acq isition - defa lt setting

(PIN n mber and condition code) ................................. 41

Tr ck data acq isition - special setting (PIN n mber) .42

Operating the horn ............................................................ 43

Opening, closing the electrical compartment cover ........ 43

F ses ................................................................................. 44

Checking, renewing the f ses ......................................44

A tomotive f ses ........................................................... 44

Main circ it f ses ........................................................... 44

F ses (options) ..............................................................45

Before loading ...................................................................46

Positioning the forks ......................................................... 47

Loading ............................................................................. 47

Transporting the load ........................................................ 48

Unloading.......................................................................... 48

Before leaving the lift tr ck nattended ........................... 48

Tow co pling ..................................................................... 49

Forced opening of overhead g ard witho t Bowden

cable ............................................................................... 49

Transport, Hoisting the tr ck.............................................50

Transporting the tr ck on a lorry or low-bed trailer ......50

Hoisting the tr ck with a crane ......................................50

Hoisting the tr ck with the eyebolts .............................. 50

Wheel change ...................................................................51

Jack locations: Changing the rear, front wheels ............. 51

Mast removal ..................................................................... 52

Towing instr ctions ........................................................... 52

Towing proced re ............................................................. 52

Tilting the mast man ally .................................................. 53

Lowering the forks man ally .............................................53

Emergency exit for tr cks with rear windscreen ..............54

Emergency exit for tr cks with polycarbonate rear

windscreen (special eq ipment)................................... 54