LTM4680

3

Rev. B

For more information www.analog.com

TABLE OF CONTENTS

PMBus Command Summary ............................ 45

PMBus Commands ................................................45

Table7. PMBus Commands Summary (Note:

The Data Format Abbreviations Are Detailed in

Table8) ...........................................................45

Table8. Data Format Abbreviations .....................50

Applications Information ................................ 51

VIN to VOUT Step-Down Ratios ............................... 51

Input Capacitors .................................................... 51

Output Capacitors .................................................. 51

Light Load Current Operation ................................. 51

Switching Frequency and Phase ............................52

Output Current Limit Programming .......................53

Minimum On-Time Considerations .........................54

Variable Delay Time, Soft-Start and Output

VoltageRamping ...................................................54

Digital Servo Mode ................................................54

Soft Off (Sequenced Off) .......................................55

Undervoltage Lockout ............................................56

Fault Detection and Handling .................................56

Open-Drain Pins ....................................................56

Phase-Locked Loop and Frequency Synchronization . 57

Input Current Sense Amplifier ................................58

Programmable Loop Compensation ......................58

Checking Transient Response ................................59

PolyPhase Configuration .....................................60

Connecting The USB to I2C/SMBus/PMBus

Controllerto the LTM4680 In System ....................60

LTpowerPlay:An Interactive GUI for Digital Power....... 61

PMBus Communication and Command

Processing .............................................................61

Thermal Considerations and Output

CurrentDerating ..................................................63

Tables 10 thru 11: Output Current Derating...........66

Table12. Channel Output Voltage vs Capacitor

Selection, All Ceramic Configuration, 15A to 30A

Load Step with 15A/µs Slew Rate ......................66

Table13. Channel Output Voltage vs Capacitor

Selection, Bulk and Ceramic Cap Configuration,

15A to 30A Load Step with 15A/µs Slew Rate ...67

Table14. Dual Phase Single Output Voltage vs

Capacitor Selection, Bulk and Ceramic Cap

Configuration, 30A to 60A Load Step with 30A/µs

Slew Rate ..........................................................68

Derating Curves ......................................................69

EMI Performance ...................................................70

Safety Considerations ............................................70

Layout Checklist/Example .....................................70

Typical Applications ...................................... 72

PMBus Command Details ............................... 77

Addressing and Write Protect.................................77

General Configuration Commands..........................79

On/Off/Margin ........................................................80

PWM Configuration ................................................82

Voltage....................................................................85

Input Voltage and Limits.......................................85

Output Voltage and Limits ....................................86

Output Current and Limits ......................................89

Input Current and Limits ......................................91

Temperature............................................................92

Power Stage DCR Temperature Calibration...........92

Timing ....................................................................93

Timing—On Sequence/Ramp...............................93

Timing—Off Sequence/Ramp ..............................94

Precondition for Restart .......................................95

Fault Response .......................................................95

Fault Responses All Faults....................................95

Fault Responses Input Voltage .............................96

Fault Responses Output Voltage...........................96

Fault Responses Output Current...........................99

Fault Responses IC Temperature ........................ 100

Fault Responses External Temperature............... 101

Fault Sharing......................................................... 102

Fault Sharing Propagation .................................. 102

Fault Sharing Response...................................... 104

Scratchpad ........................................................... 104

Identification......................................................... 105

Fault Warning and Status...................................... 106

Telemetry.............................................................. 113

NVM Memory Commands .................................... 117

Store/Restore ..................................................... 117

Fault Logging...................................................... 118

Block Memory Write/Read.................................. 122

Package Description ................................... 123

Table23. LTM4680 BGA Pinout.......................... 123

Revision History ........................................ 125

Package Photograph ................................... 126

Design Resources ...................................... 126

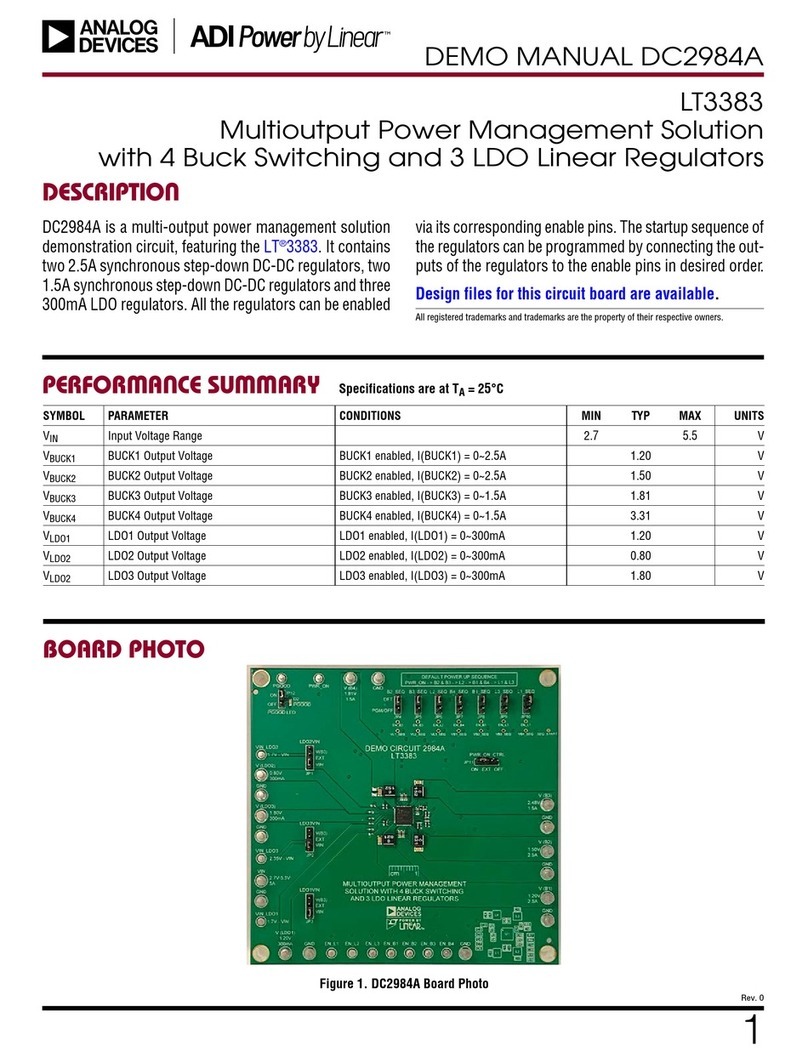

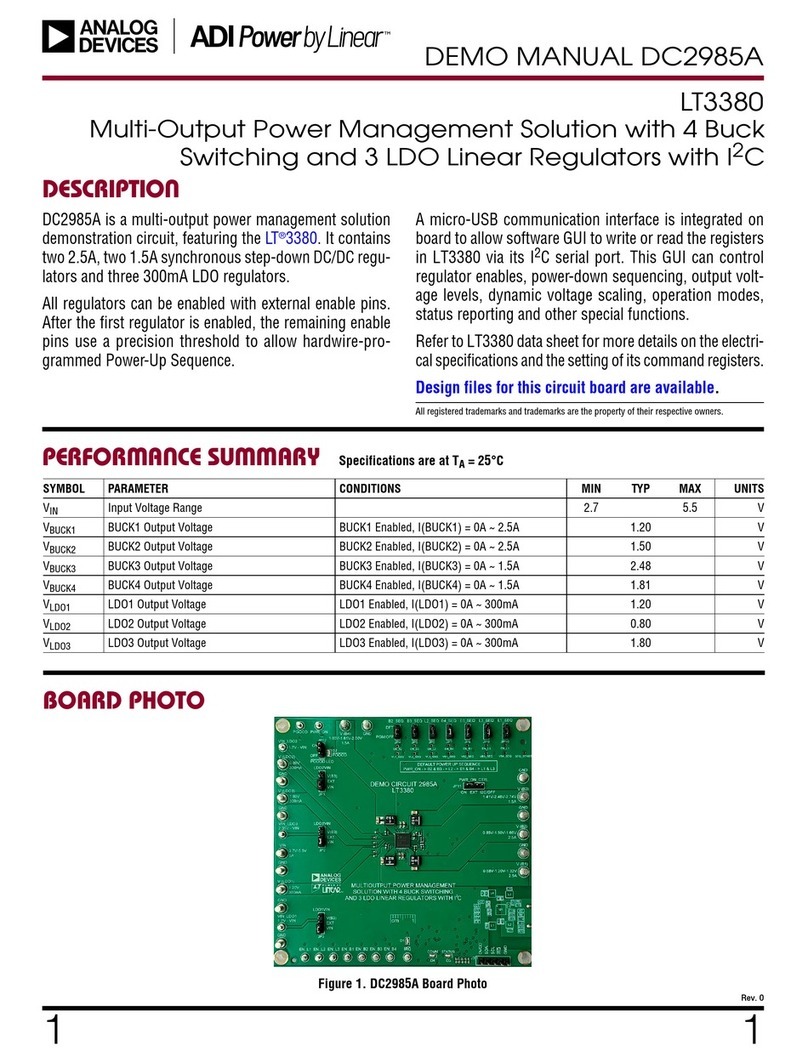

Related Parts ............................................ 126