Linear AT71-250 User manual

Other Linear Transmitter manuals

Linear

Linear DXS-31 User manual

Linear

Linear miniTransmitter Delta-3 Series Administrator guide

Linear

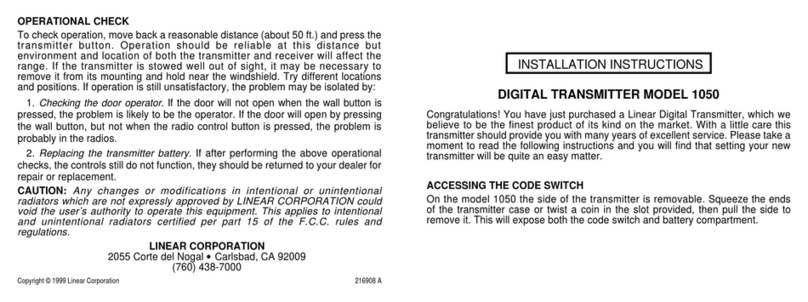

Linear 1050 User manual

Linear

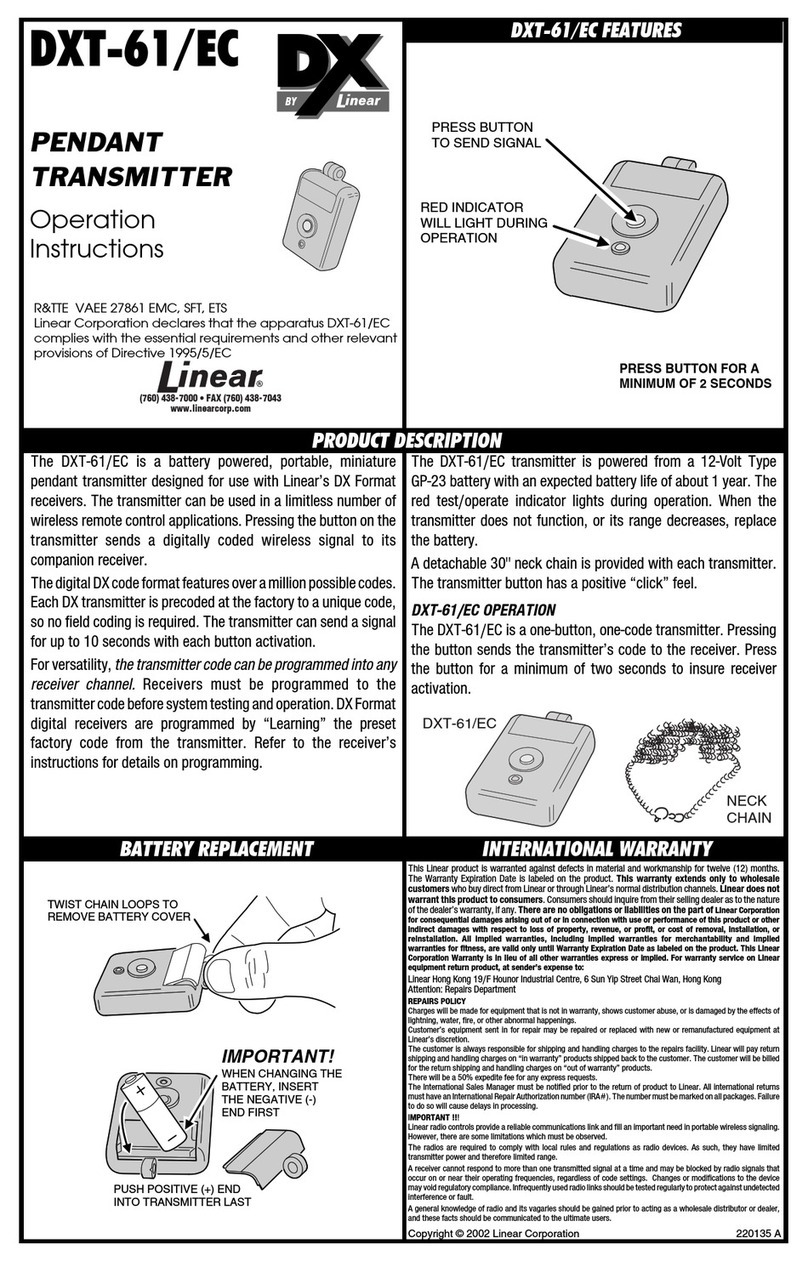

Linear DXT-61/EC User manual

Linear

Linear DT-2A Administrator guide

Linear

Linear WT00Z-1 User manual

Linear

Linear MDT User manual

Linear

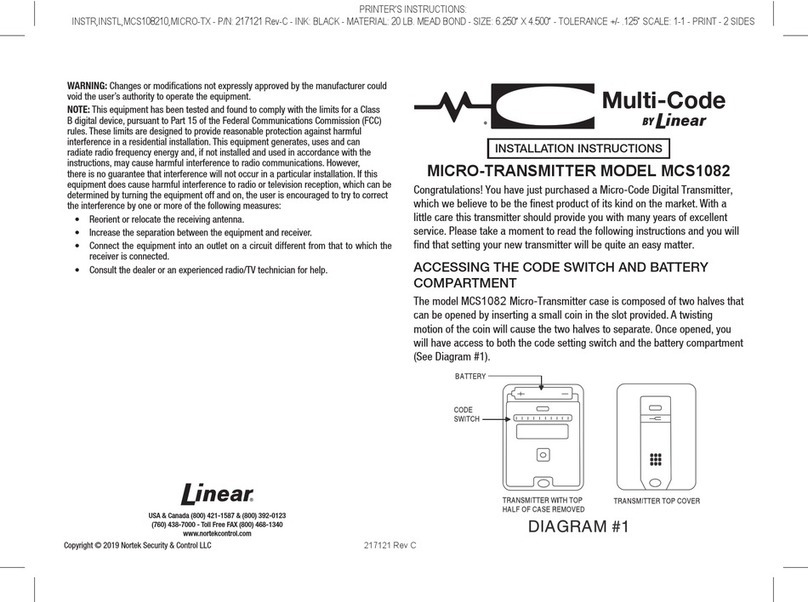

Linear MULTI-CODE 4140 User manual

Linear

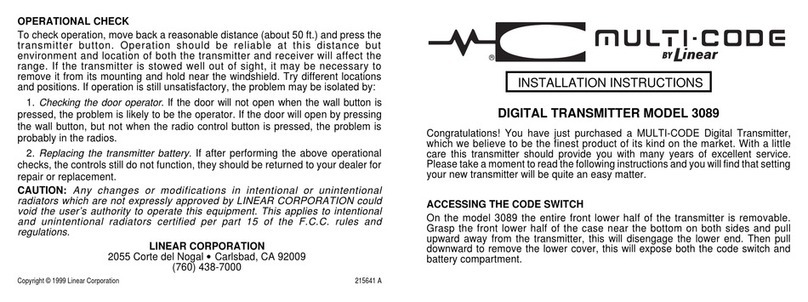

Linear Multi-Code 3089 User manual

Linear

Linear AT7400 User manual

Linear

Linear Mini-Code 3083 User manual

Linear

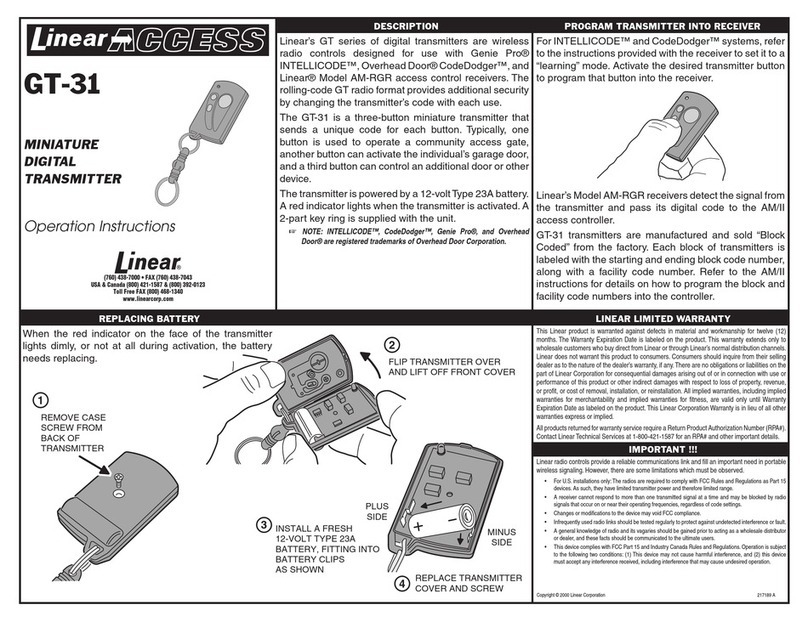

Linear GT-31 User manual

Linear

Linear LINEARCOM3000 User manual

Linear

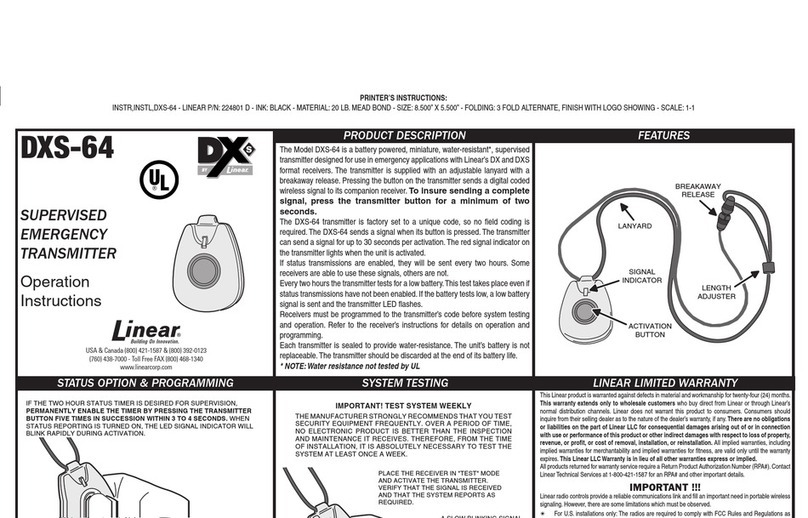

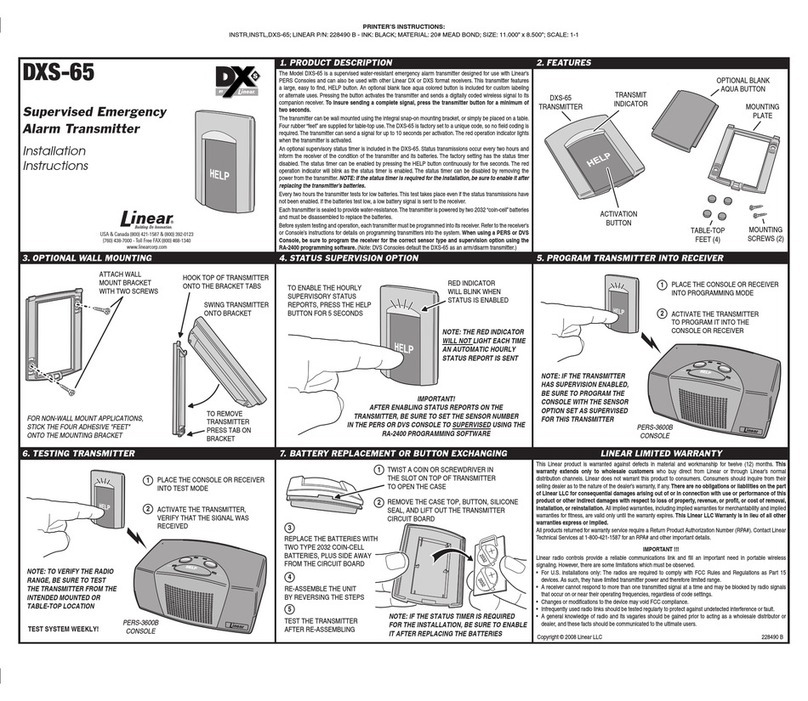

Linear Supervised Emergency Alarm Transmitter... User manual

Linear

Linear ADVANCED AT7200 User manual

Linear

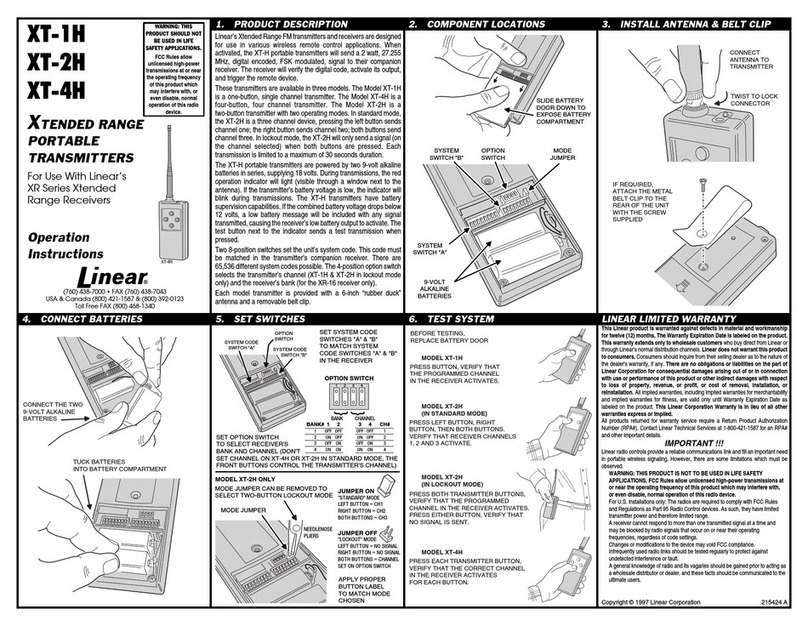

Linear XT-1H User manual

Linear

Linear LMT-1 User manual

Linear

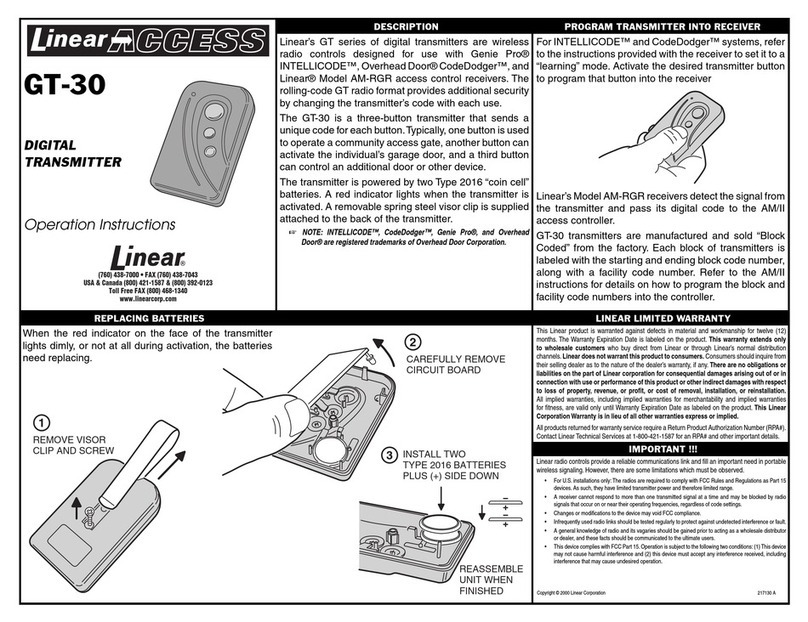

Linear DIGITAL TRANSMITTER GT-30 User manual

Linear

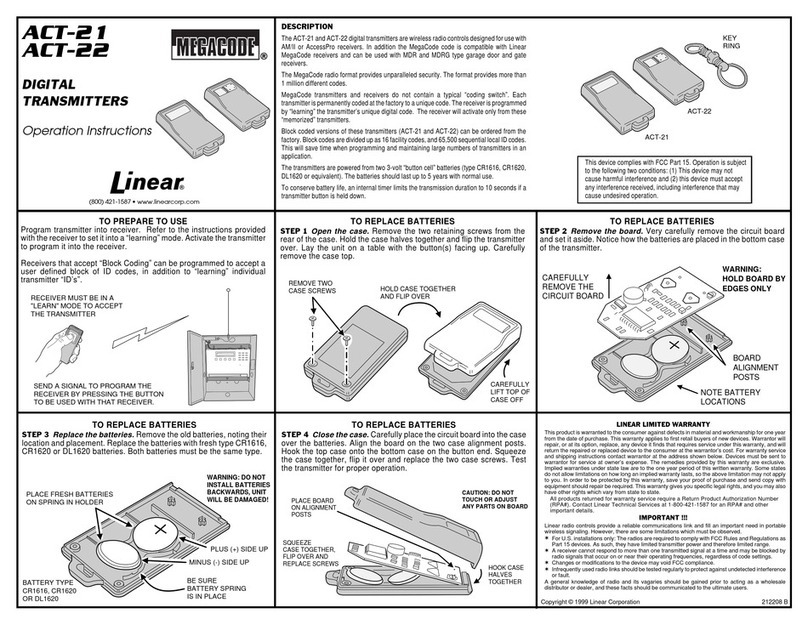

Linear MegaCode ACT-21 User manual

Linear

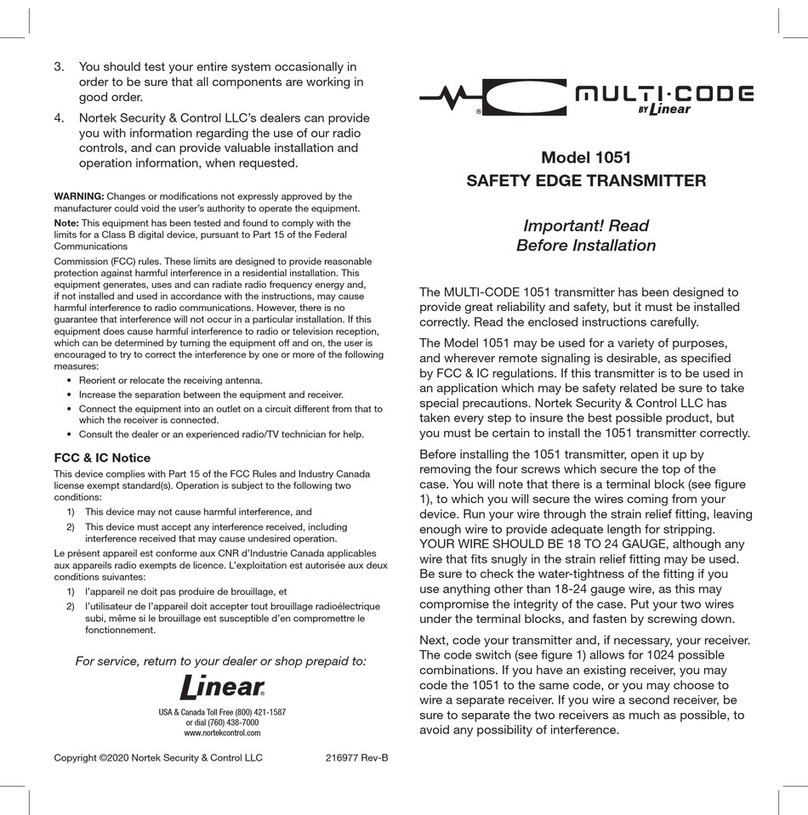

Linear MULTI-CODE 1051 User manual

Popular Transmitter manuals by other brands

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual

Honeywell

Honeywell 5816WMBR installation instructions