Instruction

Thank you for your purchase of

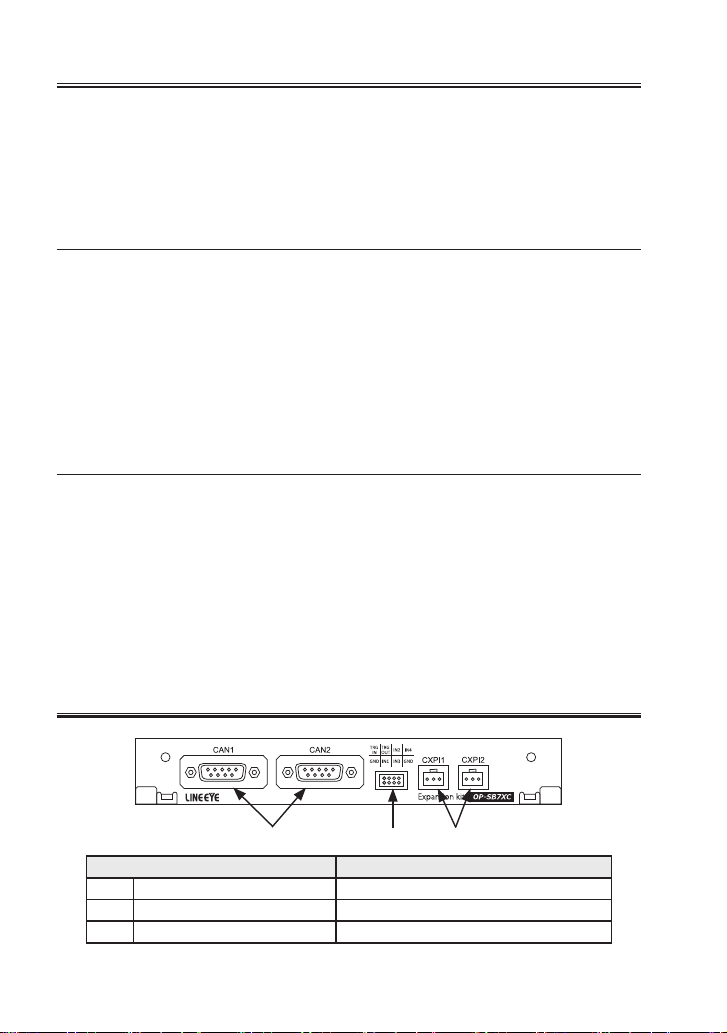

OP-SB7XC

. To use it correctly, you are

advised to read and understand this instruction manual thoroughly. Keep

this together with the warranty. If you encounter any problems, you will nd

helpful information in this manual.

NOTICE

It is prohibited to reprint or duplicate any part of the whole of this instruction

manual without prior permission from LINEEYE. The content of this

instruction manual and specications of the products are subject to change

without any notice. This instruction manual has been designed and edited

with great care to give you all necessary information. If you have any

questions, feel free to direct your inquiries to LINEEYE. LINEEYE makes

no warranty or guarantee, either expressed or implied with respect to its

quality, performance, merchantability, or fitness for a particular purpose.

LINEEYE shall not be liable for direct, in-direct, special, incidental,

or consequential damages resulting from any defect in the product. The

warranty and remedies set forth above are exclusive and in lieu of all others.

USER LIMITATION

This product has been developed for the purpose of using as an

analyzer only. When you use this product with the following devices

that are required to function with a high degree of reliability, safety

and accuracy, use it under considering the safe design of the system

in order to maintain reliability and safety for that system;

*Devices that are directly related to transportation such as airplanes,

trains, cars etc.

*Devices for crime prevention and disaster privension.

*Each kind of safety devices and so on.

This product has not been developed for the use that needs exclusivey

high reliability and safety: aerospace apparatus, trunk communication

apparatus, nuclear control apparatus, medical apparatus related with

life maintenance etc. Therefore, do no use for those purposes.

2020 by LINEEYE CO.,LTD. All rights reserved.