Lintec LC-3000L Series User manual

LN0371E2109C0

Liquid Mass Flow Controller

Instruction Manual

LC-3000L Series

Safetyprecautions

Incorrecthandling maycausedeathorinjury.

(1) Before connecting the fittings, check that no damage or defects are found on

the fittings. Make connect properly and make sure that leak test is conducted

before actual operation to prevent fluid from leaking into the atmosphere

(Hereafter, the measured fluid is called “liquid” or “fluid”).

(2) DONOTapply any fluids corrosive to the wetted materials. Corrosionmay cause

fluidtoleak into theatmosphere.Check theliquid type to be used in advance.

(3) Thedevice isnotdesigned asanexplosion-proofstructure.DO NOTuse device in a

where explosion-proof structures are required. Doingso may cause fire or explosion.

Incorrecthandlingmayleadto medium orslightinjuryormay

causedamage to,or loss of,facilities or equipment.

(1) Observetheprecautionslistedinthe WARNING (above)

(2) Strictly observe the electrical specifications. Not doingso cause fire, damage to

sensorsormalfunction.

(3) Thisdeviceisnot designed tobewaterproof.DONOTlocate thisdevice outdoors or

in a place whereit may be splashed with water. Doing so may cause fire, trouble or

malfunctionofthisdevice.

(4) DONOT modifythisdevice. It maycause fire or other problems.

(5) While a power supply is applied to the device, +15VDC and -15VDC must be

applied simultaneously. If only +15VDC or -15VDC is applied, electronic

circuits will become unstable and it may cause a malfunction.

(6) This device is not designed to handle hot swap. Please avoid attaching and

removing the power supply connector and interface connector with the power

switched on. Attachment and/or removal with the power on may result in

failure of the device.

(7) This device is a precious device,pleasehandle it carefully. Dropping down or

handlingitcarelessly will cause damage. Please use assist instrument whilemoving

orsettingthe device.

(8) Regularmaintenance is recommended for continuous useofthisdevice

(Recommended frequency is once ayear).

1.Introduction

Thismanual explains basicoperation ofthe Liquid Mass FlowController LC-3000L

Series (Hereafter, it iscalled "LC").

Please read through this manual and the separate volume “The Digital Interface Manual”

carefullyto become familiar with the featuresof this device.

2.Summary

The LC is high performance mass flow controller for gas using thermal

flow sensor and high response piezoelectric valve.

3.Features

The LM has the following features.

(1) LINTEC’s original ambient temperature compensation mass flow sensor is

incorporated for measuring flow rates.

·Low sensortemperature, long-time steady monitor, andfew problems such as

degradation ofgas to be monitored.

·The effect ofambient temperature is less because the sensor temperature is keptat

theambienttemperature.

·Steady temperature distributionofsensorand high-speed response.

(2) Digital controlby microprocessor and high-resolution A/D, D/A converter;

·High functionality

·By settingof device number (address), multiple devices canbecontrolledthrough

a single interface

·Many added functionssuch as flowtotalizer, auto-zero , and ramping functionetc.

(3) Universaldigitalinterface

(4) Superiorcorrosion resistant sealing materialsmake maintenance easy.

Metalseals (StainlessSteel 316L) are used

(5) Particle free structure

(6) By using a metal case andvarioustypes offilters, steady operation canbe achieved

even in anenvironment of high-frequency noise andstationary magnetic field

(7) RoHScompliant

(8) Bypass-less construction (Easy liquid feed and internal purging. mounting

direction: free)

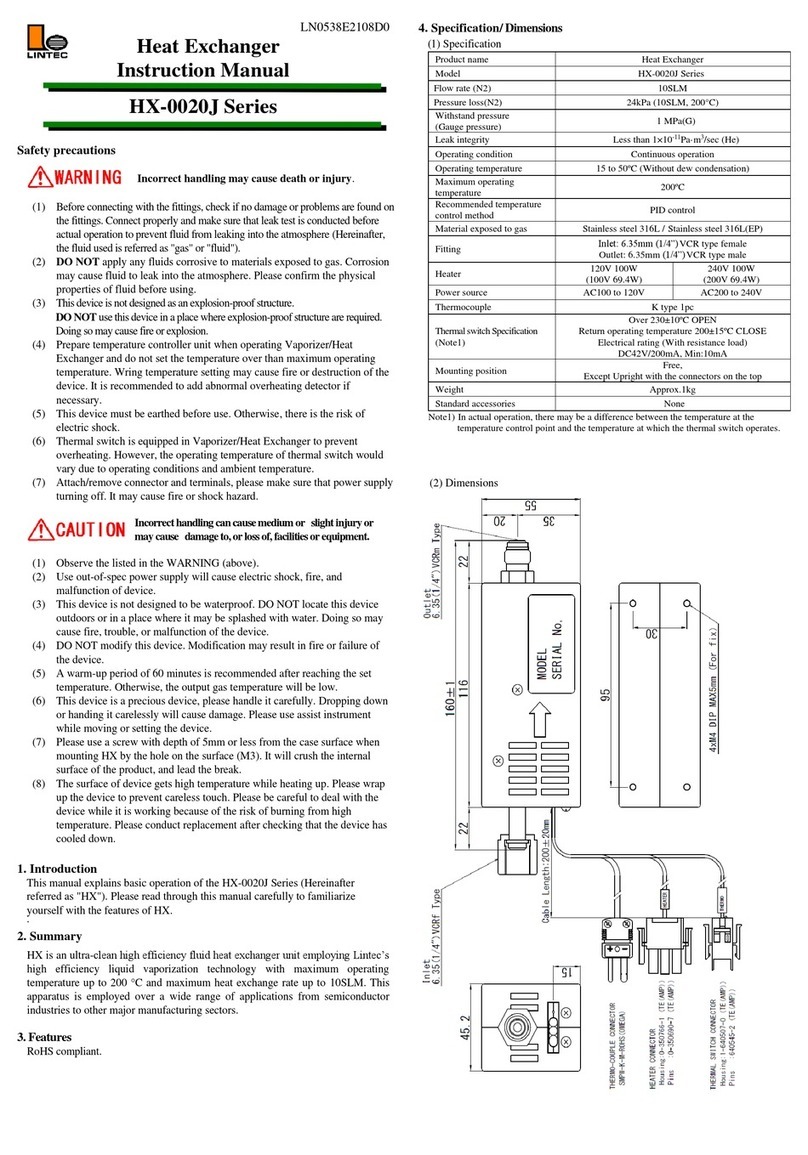

4. Specification/Dimensions

(1) Specification

Product name

Liquid Mass Flow Controller

Model

LC-3102L

LC-3202L

Precursor type and Fluid & flow

rate (except HCl, HF and other

liquidswhichcorrodestainlesssteel)

C2H5OH 0.1 to 1.0g/min F.S.

H2O 0.1 to 0.2 g/min F.S.

C2H5OH 1.0 to 2.0g/min F.S.

H2O 0.2 to 0.4 g/min F.S.

Operation of external valve

Piezo actuator / Normally Open

Surface treatment

NO: No treatment (no surface treatment)

MO: Precision polishing

Minimum control flow rate

5% F.S.

Analog flow rate setting signal

0 to 5VDC (Proportional to flow rate)

Analog flow rate output signal

0 to 5VDC (Proportional to flow rate)

Accuracy (Note1)

±1.0 %F.S.

Repeatability (Note1)

±0.5 %F.S.

Operating differential pressure

(Note1)

50 to 300 kPa(D)

Maximum operating pressure

(Note1)

300 kPa(G)

Pressure Limit

1MPa(G)

Operating temperature & Humidity

(Note2)

15 to 35°C· 0 to 80%RH

(Dewing should be avoided)

20 to 30°C· 0 to 80%RH

(Dewing should be avoided)

Temp. coefficient

(Note2)

(Reference Temp.25)

Zero

±

0.1 %F.S./

℃

Span

Leak integrity

Less than 1×10-11 Pa·m3/sec (He)

Recommended gas for pushing

the liquid (Note3)

He

Storage temperature& Humidity

0 to 60 °C

·

0 to 80 %RH (Condensation should be avoided)

Mounting direction

Free

Wetted materials

Stainless Steel 316L,

PCTFE

Stainless Steel 316L,

PFA, Ni-Co

Seal materials

Au

Fittings

3.2mmVCR(male), 6.35mmVCR(male), 3.2mmSWL

Digital interface connector

RS-485 (RJ45 modular jack) 2-wire system

Power supply

+15VDC±3% 100mA, -15VDC±3% 50mA

Inrush current

(Actual measurement value)

+15V: 11A 130 µs -15V: 9A 110 µs

Analog interface connector

D-sub connector (Fixed size of screw M3)

Weights

Approx.1kg

Note1)Whenusingasa liquidcontrollerforvaporizationsystem, please refertothespecification

sheetof vaporizationsystem.

Note2)Theflowrate willbenot accurateiftheliquidtemperature isdifferent fromsurrounding

temperaturewhen measuring or controlling, please setthesametemperature forliquidandthe

device.

Note 3)There is the possibilityoffailureabout measuringandcontrolling.Toreduce thegassolubilityof

theliquid, Helium(He)is recommendedtobe thepressurizedgas.

· Connectthe LCtothe frame ground.

· Flowratecalibrationis done byC2H5OH or H2O.

· Liquid with solid materials can’t be controlled.

· Ifthemixture ratioofmixture liquid ischanged,pleaseconsultus inadvance.

· Ifthereare particlesinthe target liquid,installafilterto remove particles more than 0.2μm on the

primaryside(theinletside).

· The viscosityofliquid controlledby theLCshould be less than 0.1Pa·s (100cp). Pleaseconsultusif

the viscosityofliquidishigh.

· Pleasefeedin the liquidafter completely purging(Recommended).

(2) Dimensions

3.2mm VCR (male) 112mm specification

5. Ordering Information

LC - 3*02L -MO -22 VR1 JA0A0

[1] [2] [3] [4] [5] [6]

[1]SeriesModel LC: Liquid Mass Flow Controller LC Series

* Dependsonthe flow rate

[2] Seal type (Surface treatment)

NO: No treatment

MO: Precision polishing treatment

[3]INLET,OUTLET fitting size (IN side,OUT side)

E.g. if: 3.2mm, OUT:3.2mm, label as [22] 2 indicates size is 3.2mm

[4]Fittingtype

VR1: VCR-compatible 112mm SWL: SWL127.4mm

* Dependsonthe fittingsize

[5] Option J: 2%Close (This option “J”isrecommended)

[6] Other options

Non-option setting is labeled “AA0A0”, please consult for more information.

6. Connection

(1) Analog interface connector

Mounted connector :D-Sub 9pin (male) Pair connector :D-Sub 9pin (female)

(Fixed size of screw M3)

Pin No.

Signal Name

Function

1

Valveoverrideopen/closesignal

(Note 4)

+15VDC:Open, -15VDC:Close

2

Flow rate output signal 0 to 5 VDC

Flow rate of power output (plus side)

0 to 5 VDC

3

Power supply +15VDC±3%

Power supply (plus) (100mA)

4

Power supply COMMON

(Note 5)

Power supply COMMON ±15VDC

5

Power supply -15VDC±3%

Power supply (minus) (50mA)

6

Flow rate setting signal

0 to 5 VDC

Flow rate of power input (plus side)

0 to 5VDC

7

Flowrate outputCOMMON(Note5)

Flow rate output signal COMMON

8

Flowrate settingCOMMON(Note5)

Flow rate setting signal COMMON

9

N.C.

-

Note4) Theimpedanceofthe input setting offlow rate voltage is 100kΩ, the resistanceofvalveopen

andcloseis 100kΩ.

Note5) PinNo. 4,7,8areconnectedinthisdevice.

Toavoidtheeffect ofCOMMONpotentialdifference, pleasefollowthecircuitasbelow.

If the high accuracy of the control is necessary, setting flow rate voltage is COMMON

(Pin.8), and the flow rate output is COMMON (Pin.7) on the power side. Please do not

connect the power COMMON (Pin4).

(2) Digital interface connector

Mounted connector: RJ45 modular jack Pair connector: RJ45 modular plug

Pin No.

Name

Function

1

Signal COMMON

RS-485 Signal COMMON

2

Signal COMMON

RS-485 Signal COMMON

3

N.C.

-

4

Signal [-Txd/Rxd]

RS-485 2 -wire system transmitter.

receiver minus signal

5

Signal [+Txd/Rxd]

RS-485 2- wire system transmitter.

receiver plus signal

6

N.C.

-

7

N.C.

-

8

N.C.

-

7. Alarm function

This LC features two alarm modes: alarm A and alarm B. Using a digital interface,

alarm output of the digital connector or LED indicator located on top of the LC can

monitorthe alarm status. Alarm setting can only be changed through digital

communication, so if a change is required, please do it through communication.

Details are described in the digital interface manual and others.

Alarm

Set off

LED indicator

A

Setting value ≠ Flow rate output

Continuous Red

Flow totalizer Alarm level 2

Powersupplyvoltagedrop(+15VDC)

Off

B

Valve voltage offset (At controllers)

Red (every 0.5sec flashing)

Zero adjustment error (Note6)

Flow totalizer Alarm level 1

Other

Command error

Continuous Red (every 0.5sec flashing)

Normal

-

Green (every 1sec flashing)

8. Initial setting value (factory shipped value)

This device is provided with a software switch for operation mode setting. Before

operation, input the necessary data for various functions by using the digital

interface. Details of the functions are described in the digital interface manual etc.

Software switch

Available values

Function

Default

Device number

00 to 99

LC No. Registration

00

Alarm A range

1 to 99 [%]

Setting Alarm A range

5%

Alarm B range

1 to 99 [%]

Setting of Alarm B range

20%

Alarm timer

0 to 99 [seconds]

Setting of time to prohibit Alarm

5seconds

Alarm A output

Enable / Disable

Setting ofAlarm A LED display

Enable

Alarm B output

Enable / Disable

Setting of Alarm B LED display

Disable

(Note 6)

Operation mode

Analog / Digital

Switching of Analog/digital

Analog

Power on mode

Analog / Preset

Switching of Operation mode in

power turning on

Preset

Valve control

C / O / H / S

Close / Open / Hold / Servo

Servo

Control speed

FAST / SLOW

Switching of Response speed

FAST

Control mode

(Note 7)

2%Close/2%Hold/Normal

Control mode setting at flow rate setting<2%.

2%Close: Valve Close

2%Hold: 2% Control

Normal: Normal Control

2%Close

Communication

protocol

9600 to 38400bps

8bit / 7bit

Odd/Even/ None

1bit / 2bit

Baud rate

Character length

Parity

Stop bit

9600bps

7bit

None

2bit

Note6)Zero adjustment error alarms regardless of the “Enable” / “Disable” of the alarm.

Note7)Thistableisthe settingwhen less than 2% Closesetting"JA0A0" isspecified.

· If the zero adjust button on the top of the device is pressed and held for over 5 seconds,

the communication protocol is reset to default value (factory shipped value).

9. Operation

(1) Preparation, operation

1) This product is packedin aclean room before shipment. Please break the seals in a

clean room after taking it out of its box.

2) Checktheliquidtypeand flowrate,and check the directionofthe gasflowandthe

MFC before installation.

3) Check forgas leaks from thetubing with ahelium(He)leak detector.

4) Connect the interface connectorsaccording to theConnector table.

5) Powerrequirementsare+15VDC:100mAand-15VDC:50mA.

Checkthevoltage,polarity andcapacitanceofthepower supplyvoltage.

6) Turn on the power supply and let the equipment warm up for at least 5

minutes (Recommended time: 30min).

7) Adjust thezeropoint by pressing thezero-adjustment switch located on the top of

the LC. Before zero adjustment, check that liquid is not being suppliedand

the device was warmed up for 30 minutes or more in order to ensure sensor

stability.

8) Inputtheflowratesettingsignalandsupplygaswithrequireddifferentialpressuretothe

LC. The LCwillbeginto controltheliquid flowinproportionto the presetvoltage.

Full-scalevoltageis5VDC.Maximum input voltage is ±15.5VDC.

9) When the output flow rate signal is used, the tolerance voltage of the external

device shouldbemorethan±15.5VDC.When thepower issupplied,there isthe

possibility to achieve the maximum voltage in the range of ±15.5VDC.

10)When a highly reactive liquid is used, thoroughly purge all foreignmatter from

the tubing and the LC before operation.

11)When contaminated liquid is used, install a filter at the equipment inlet.

12)Use the LC within the range of the operating temperature, and keep it at the

same temperature with the gas. If used

inany environmentthat does not meet the above-mentioned requirements,

the flow rate cannot be measured accurately and the device may fail.

13)Do not switch the power supply on and off within one second. It may cause

failure.

14)Helium(He)gas is recommended for pushingthe liquid. If anyother gas is used,

thedissolvedgas will produce bubbles, and it may make the controlunstable.

15)Bubbles may become the cause oftheunstablecontrol. So, perform the vacuuming

of liquid line thoroughly before the introductionofliquid(Recommended).

(2) Usage ofthe digital interface

This unit supports RS-485 interface. Therefore, with the use of the digital

interface, high performance liquid mass flow control can be achieved. Please

refer to the digital interface manual.

10. Product warranty

(1) Period

This product is guaranteed for a period of 1 year from the date of

shipment. Defects are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other damage

caused by this product is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty.

1) Failure caused by by-product of liquid or gas used

2) Failurecausedbymisuse(includingcarelessoperation)or incorrectrepairormodification

3) Failure caused by falling or dropping after purchase

4) Failure caused by fire, earthquake, flood, lightning or other naturaldisasters

Even if the warranty period is still in effect, repair service may not be provided

in the following cases.

1) When the kind of liquid or gas used in the product is unclear

2) The product is returned with liquid or gas remaining inside and safety cannot

be confirmed

Please be aware that this device is a precision instrument and the generation

of excessive electrical noise, changes in liquid temperature or pressure

fluctuations may result in unstable control.

This instruction manual is subject to revision without notice.

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23 Sekinotsu, OtsuCity,ShigaPref.520-2277,Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo 160-0004, Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

This manual suits for next models

2

Other Lintec Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Nakanishi

Nakanishi AL-M1202 Operation manual

Novexx Solutions

Novexx Solutions EIDOS XTO Series user manual

Tetratec Instruments

Tetratec Instruments LFE-LDS Operation manual

Lillbacka Powerco

Lillbacka Powerco Finn-power P51MS manual

Kongskilde

Kongskilde ITF 80 manual

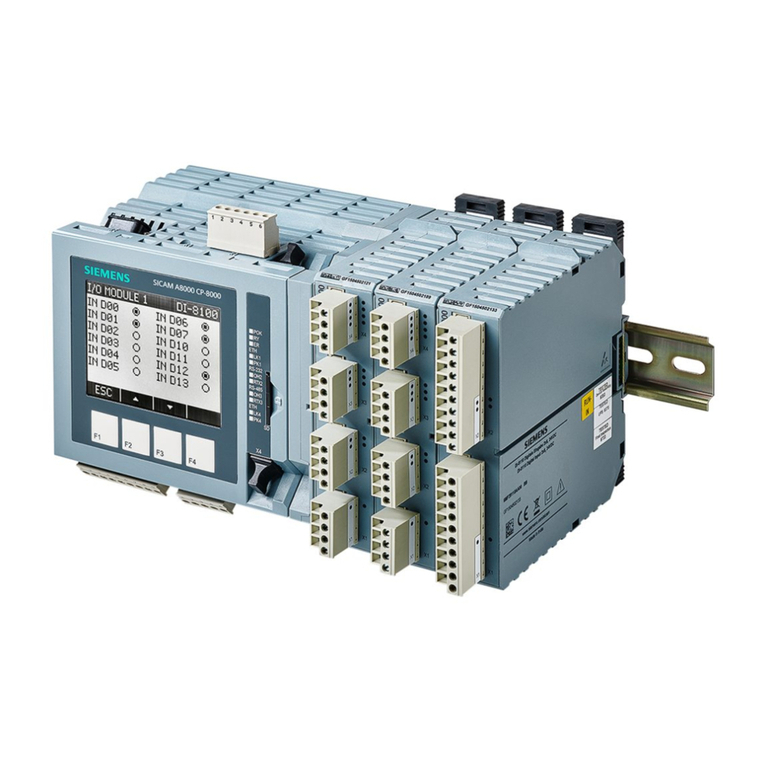

Siemens

Siemens SICAM A8000 Series quick start guide