Description

The Lion Precision LRD8200 Label Sensor uses ultrasonic technology to monitor label registration

and/or count labels. A change in the sensor output indicates the presence of a label edge.

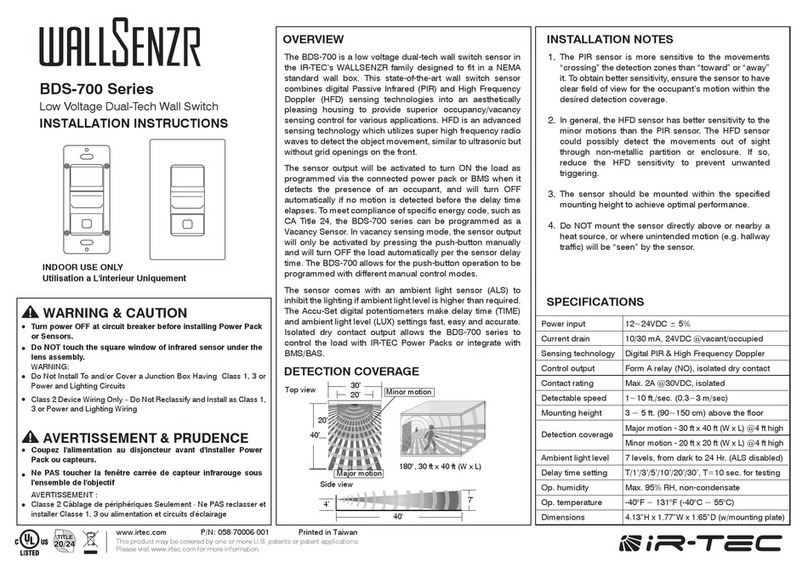

Connecting to the Sensor

Warnings:

Sensors must not be attached to voltages in excess of 30 VRMS or 60 VDC

All external connections must be SELV (Safety Extra Low Voltage). A shielded cable is required for

full protection and safety compliance.

All power must be off when installing the sensor.

Use of the equipment in any other manner may impair the safety and EMI protections of the

equipment.

If outputs are overloaded, all indicators on the sensor will flash together and sensor will stop

operating. Normal operation will be restored when the overload is removed.

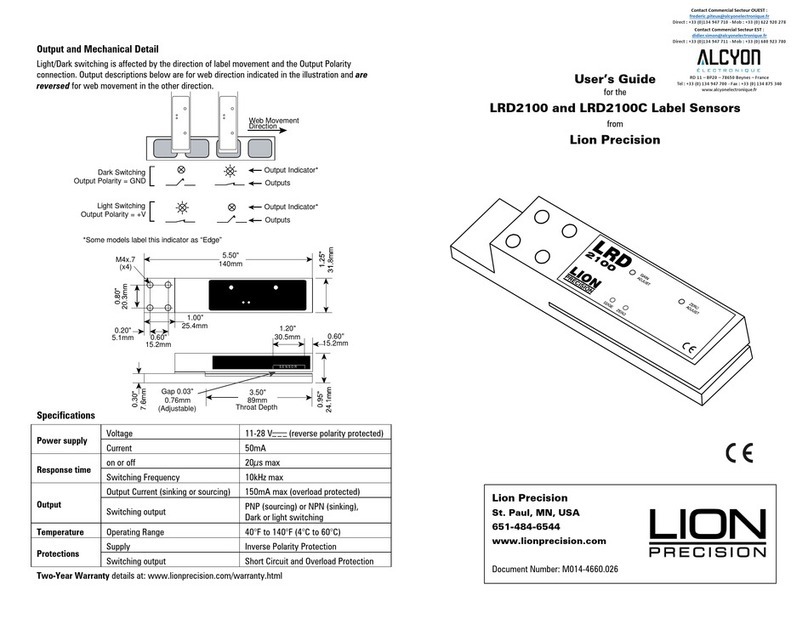

Wire

Color

Connection Notes

1 (Brown) Vin (12-24 V ) 50 mA max.

2 (White) NPN Output 150 mA max.

3 (Blue) Ground Connected to

sensor body

4 (Black) PNP Output 150 mA max.

Shield Ground Sensor Case

Any other wires in the cable (if using 5 wire) are

not connected in the sensor and can be ignored.

Specifications

Power supply Voltage 12-24 V (reverse polarity protected)

Current 50 mA

Response time On or Off 125-425 µs max

Switching Frequency 1 kHz max, 250 m/min for 2mm gaps

Output

Output Current (sinking or sourcing) 150 mA max (overload protected)

Switching output PNP (sourcing) or NPN (sinking),

Dark or light switching

Registration Accuracy 60 m/min: 0.15 mm (0.006")

250 m/min: 0.60 mm (0.024")

Temperature Operating Range 40°F to 140°F (4°C to 60°C)

Protections Supply Inverse Polarity Protection

Switching output Short Circuit and Overload Protection

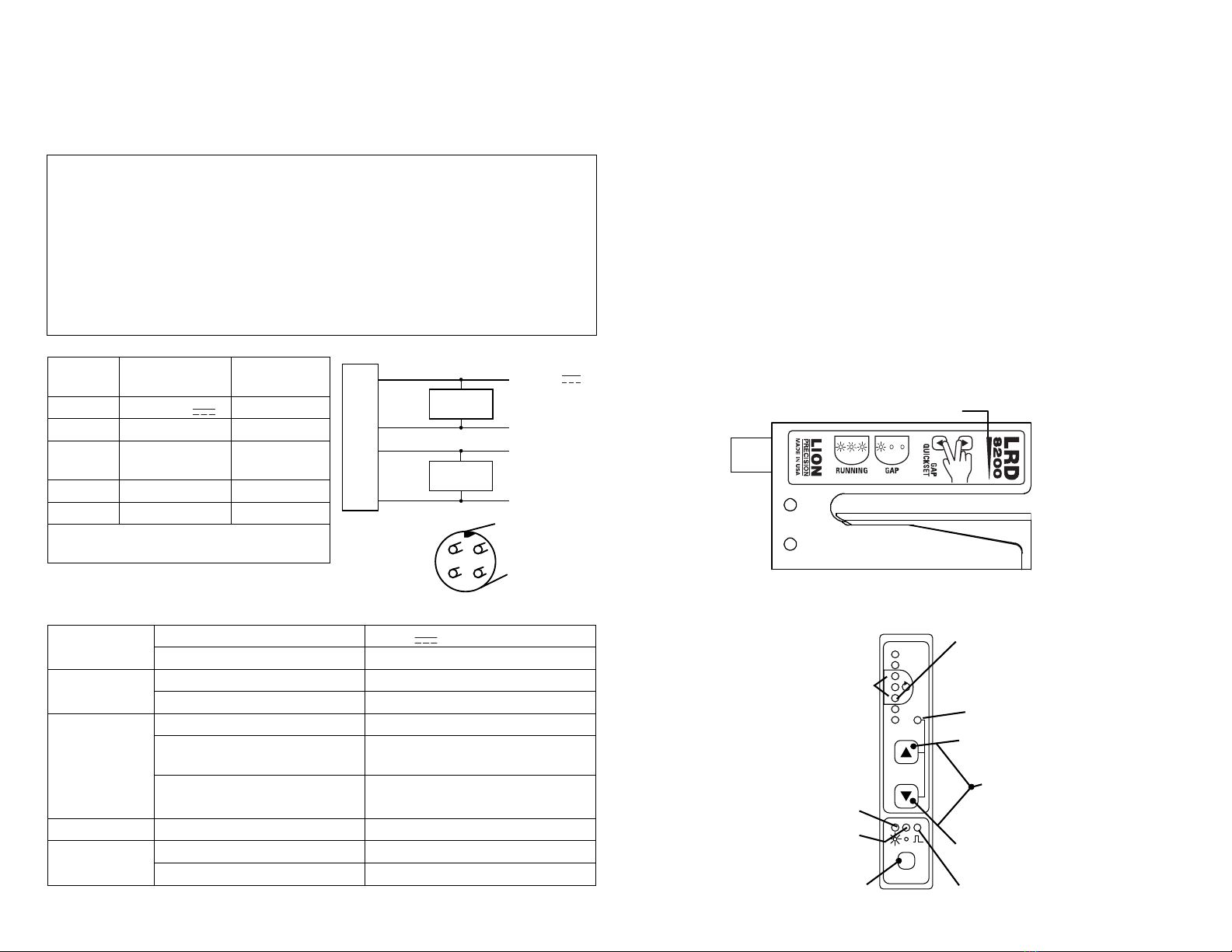

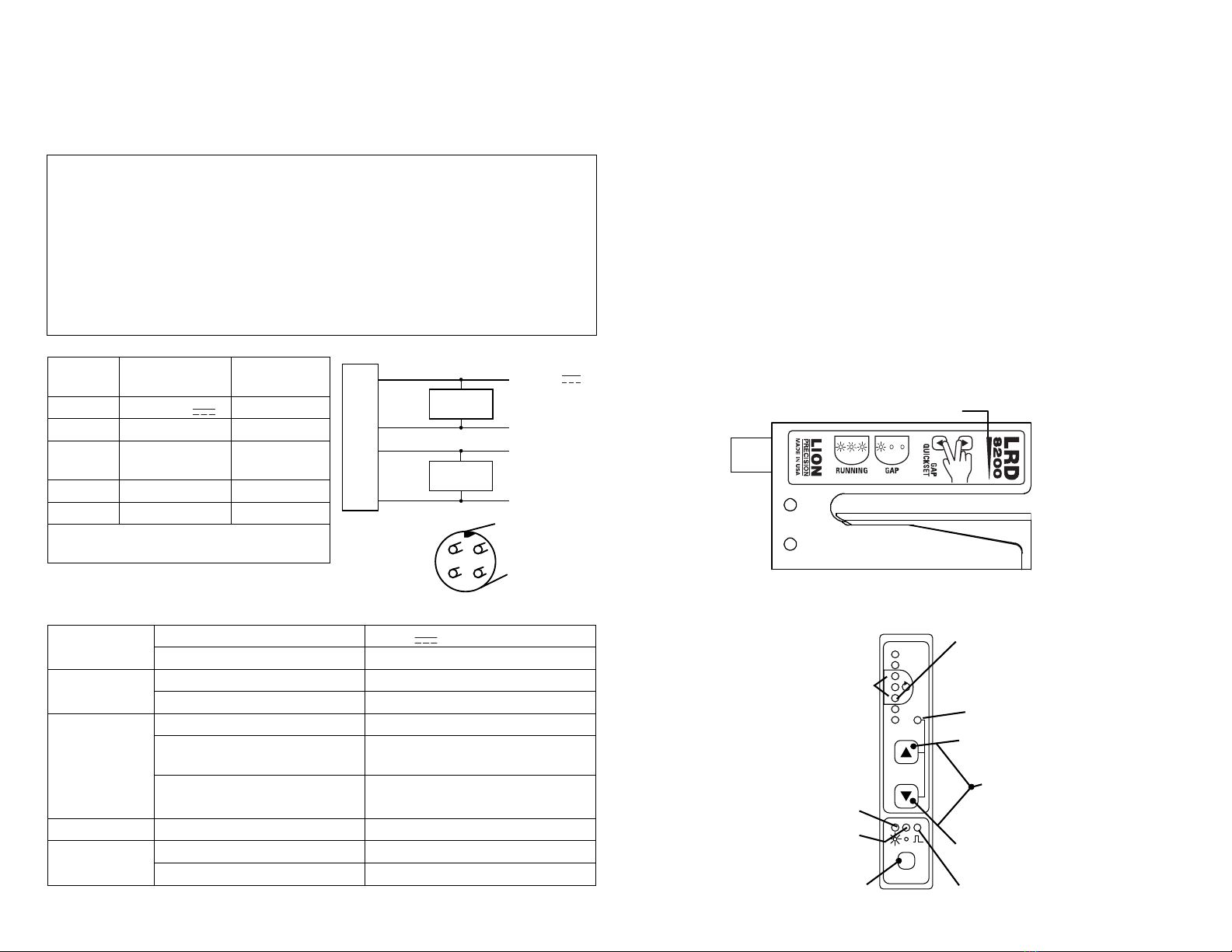

Sensor Setup

1. Labels must pass under the “Sensing Area” indicator (see fig. 1).

2. Place a gap in the sensor (or remove a label and place the liner only in the sensor)

3. Press both Adjust buttons at the same time to quicly set the sensor, or…

a. Manually use Adjust buttons to light the “Gap Setup” light on the light bar (see fig. 1, 2).

4. Run labels through the sensor to verify that the three “Running” lights (see fig. 1, 2) are active

(on or flashing) while labels are passing through the sensor. If not, use Adjust buttons until

they are. More lights than the three “Running” lights may be active while running labels.

5. If sensor is not performing satisfactorily, adjust up and/or down a few clicks and see if

performance improves, but always keep the three Triple-Check lights on when running.

For best performance, web must remain in contact with the base plate.

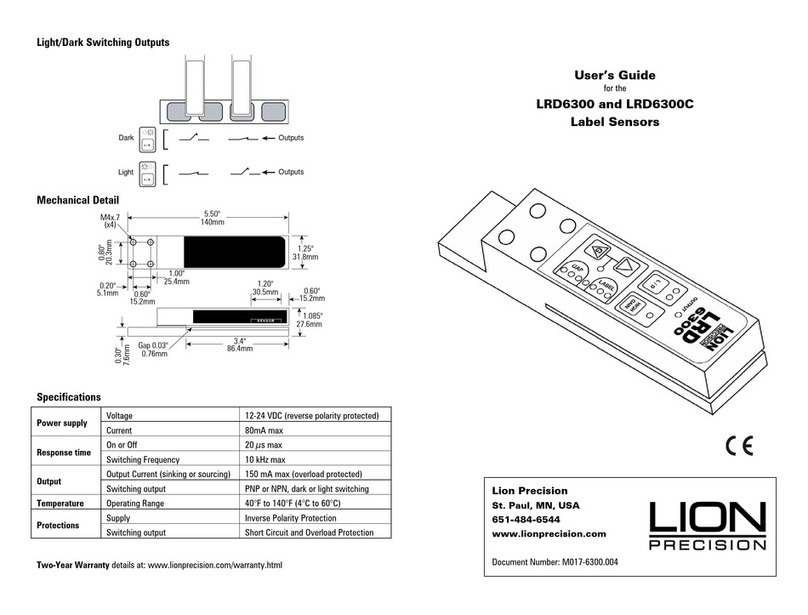

Light/Dark Switching

Light/Dark switching mode (see Fig. 3) is displayed by the Light/Dark Indicators (see fig. 2).

To change between light and dark switching, hold the Light/Dark Select (“1S”) button for 1 second.

1 (Brown) +12 to 24

NPN Output

150 mA max.

PNP Output

150 mA max.

Ground

2 (White)

3 (Blue)

NPN Load

PNP Load

4 (Black)

M12 connector on rear of sensor

21

4

3

Sensing Area Indicator

Fig. 1

1s

LIGHT/DARK INDICATORS

Light Switching

Dark Switching

LIGHT BAR &

Triple-Check Verification

Running Lights

While running, these three

lights (or more) are active (on or flashing)

when properly adjusted

OUTPUT INDICATOR

Light is on when outputs are on/conductin

LIGHT/DARK SELECT

Changes between light/dark switching

Must be held for one second to change.

UP ADJUST

Shifts light bar up

Hold down for rapid adjustment

GAP QUICKSET

Press both adjust buttons to

quickly set the gap level

DOWN ADJUST

Shifts light bar down

Hold down for rapid adjustment

ADJUST ACKNOWLEDGE

Light flashes green with

every ADJUST key press.

Flashes red when adjustment

is at maximum.

GAP SETUP LIGHT

Adjust to be on when gap

(or liner only) is in sensor

Fig. 2