Warnings:

Sensor body is connected to Ground.

Sensors must not be attached to voltages in excess of 30VRMS or 60VDC

All power must be off when installing the sensor.

Use of the equipment in any other manner may impair the safety and EMI protections of the

equipment.

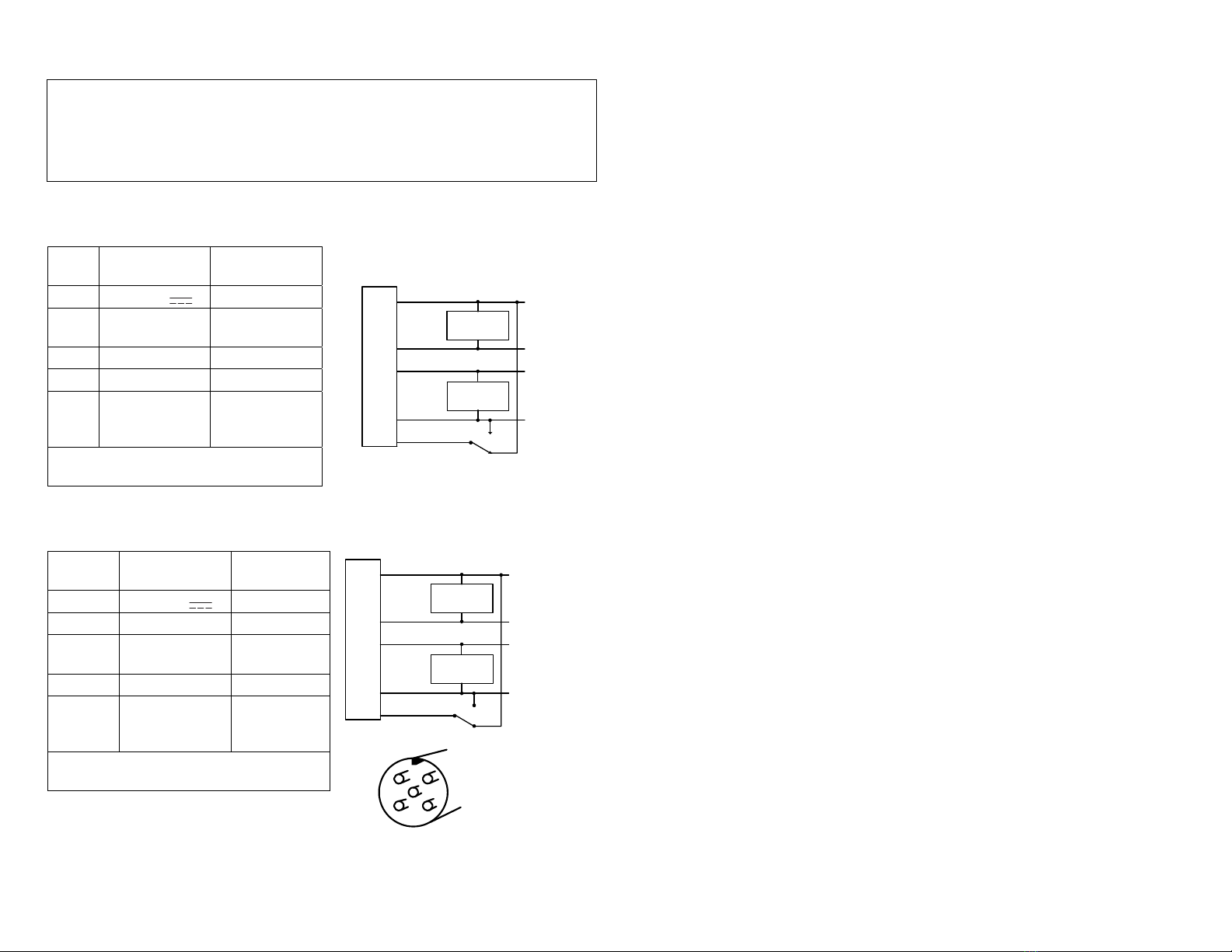

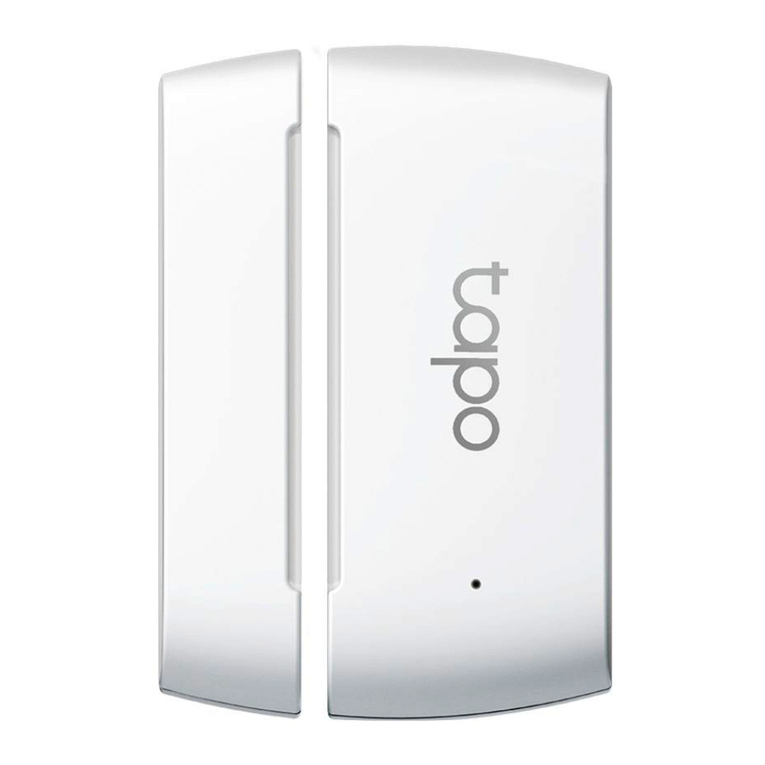

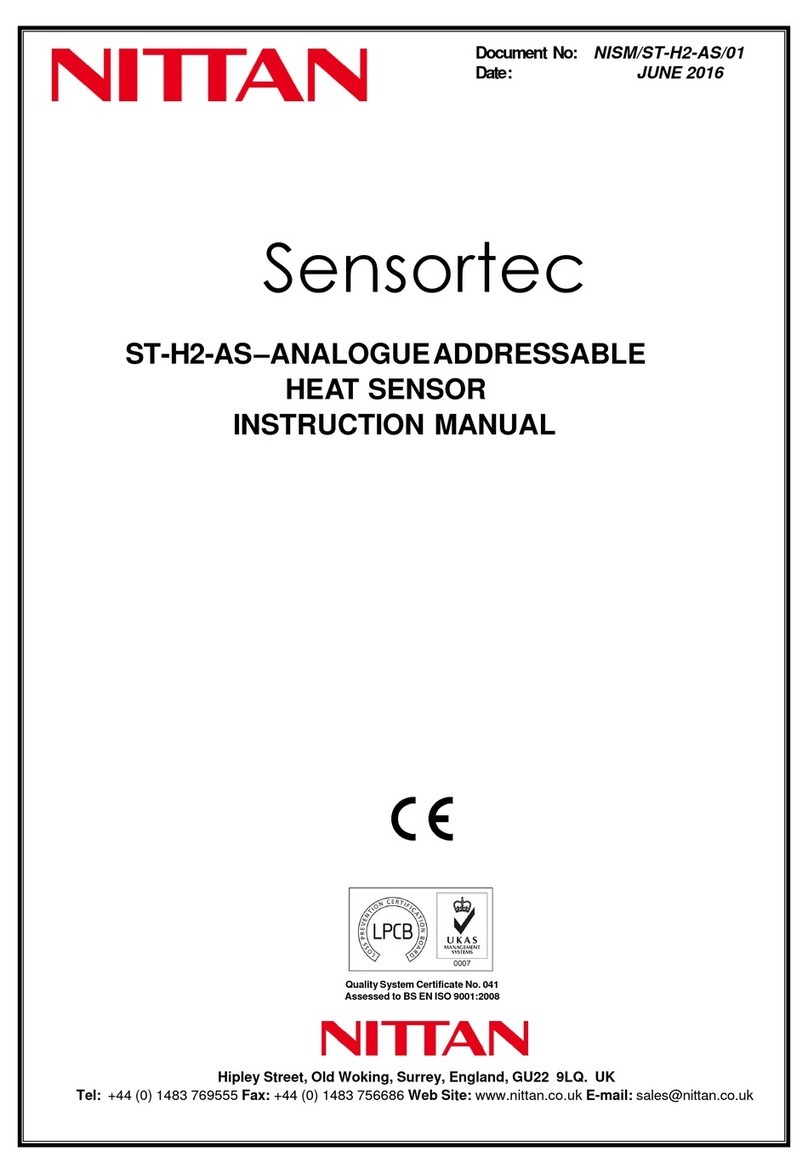

LRD2100 Wiring

Wire

Color

Connection Notes

Red Vin (11-28V ) 50mA max.

Black Ground Connected to

sensor body

Green NPN Output 150mA max.

Blue PNP Output 150mA max.

Brown Output Polarity

(light/dark

switching)

+V or Ground

See detail on

back

Warning: Brown wire must be connected to +V

or Ground for reliable operation.

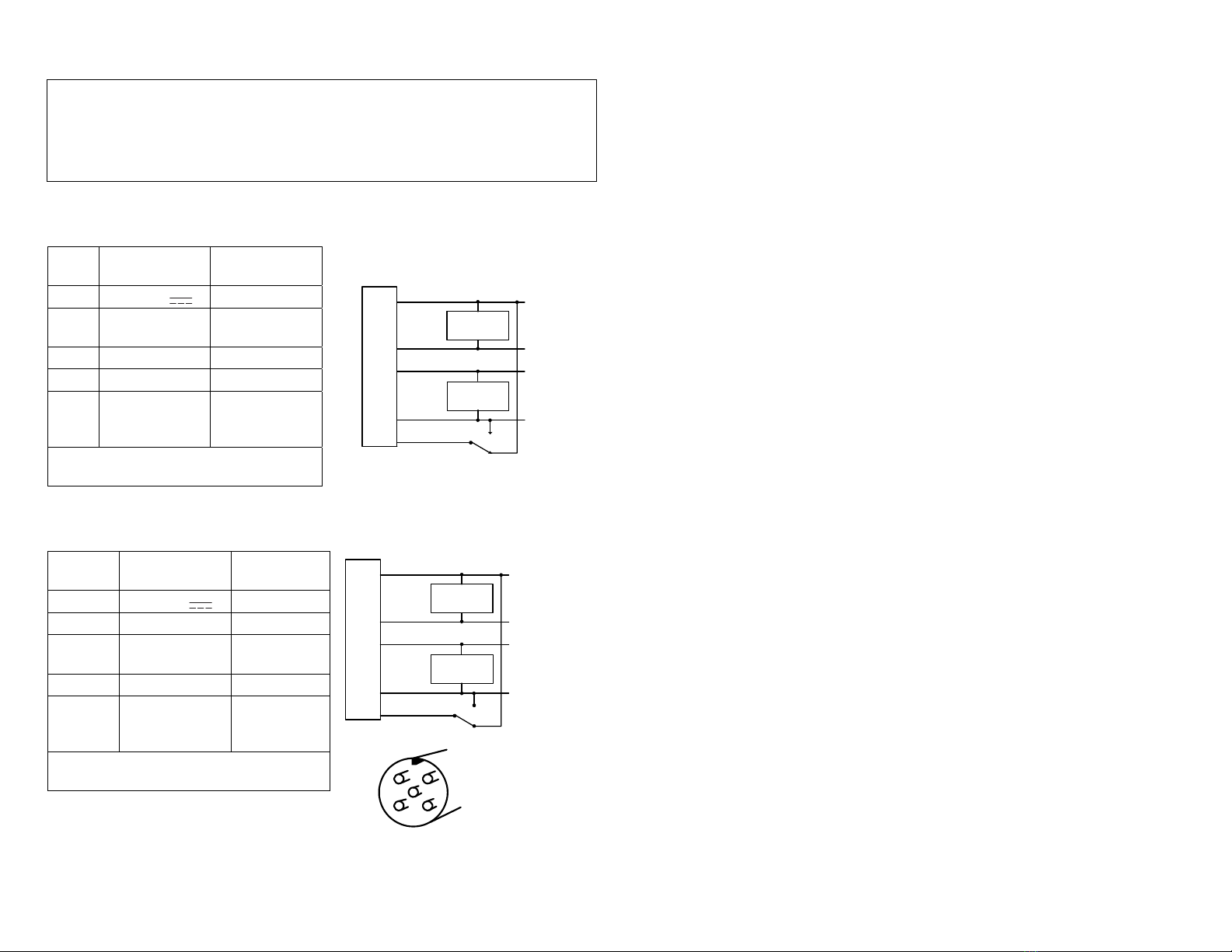

LRD2100C Wiring

Wire

Color

Connection Notes

1 (Brown) Vin (11-28V ) 50mA max.

2 (White) NPN Output 150mA max.

3 (Blue) Ground Connected to

sensor body

4 (Black) PNP Output 150mA max.

5 (Gray) Output Polarity

(light/dark

switching)

+V or Ground

See detail on

back

Warning: Gray wire (pin 5) must be connected to

Vin or Ground for reliable operation.

See www.labelsensors.com for helpful information.

Adjusting the LRD2100

The adjustments on the LRD2100 have a maximum of four (4) turns. If they are turned beyond the

end points, the adjustments will continue to turn without damaging the sensor, but no further

adjustment will occur.

Adjustments When First Installed On A Machine

1. Remove all material from sensor.

2. Set GAIN ADJUST to maximum by turning at least four (4) turns clockwise.

3. Set ZERO ADJUST

Turn the Zero adjustment to where the Zero light changes between On and Off. It’s not

important whether it is On or Off when completed, as long as it is close to where it changes.

4. It is recommended that you place a round black label (several are included with the sensor)

over the Zero adjustment to prevent unnecessary adjustment in the future.

5. Set GAIN ADJUST to midpoint by turning two (2) turns counterclockwise

This setup will work with most labels and not require readjustment. The Zero may have to be

adjusted again if the baseplate or spacer is ever replaced or removed.

Adjustments When Label Stock Is Changed

Usually None. The basic setting above (Gain at center of its range) will work for most labels.

Very small labels may require an increase in Gain.

If, and ONLY if, the new labels aren't being detected correctly, use this procedure:

1. Re-Set the Gain to center of its range

a. Turn the Gain adjustment at least 4 full turns clockwise

b. Turn the Gain adjustment 2 turns counterclockwise

Run and see if the sensor works correctly. If it does, the Gain had been adjusted and needed to be

re-centered.

If it still does not work correctly, then use this procedure to fine-tune the Gain setting

1. Set Gain to Minimum by turning it 4 turns counterclockwise

2. Move labels through the sensor and increase GAIN (turn clockwise) until the OUTPUT light

("EDGE" on older models) just begins to flash.

If possible, it may be easier to create some slack in the web and just move one gap back-and-

forth through the sensor while adjusting.

3. Turn the Gain adjustment another half-turn clockwise.

4. If the sensor still doesn't detect labels reliably, you may have label materials that require an

LRD6110 or LRD8200.

Lights During Operation:

The OUTPUT light (EDGE on older models) indicates the sensor output. It will be in one state (on or

off) during the label and the other state during the gap depending on the direction of the label

movement and the connection of the Polarity Invert wire (see next page for details).

The Zero light is for first-time setup only and is meaningless during operation.

Notes:

1) For best results, web should ride against sensor baseplate, not “float” in the gap.

Red +11 to 28VDC

NPN Output

150mA max.

PNP Output

150mA max.

Ground

Polarity Invert

Green

Black

Brown

NPN Load

PNP Load

Blue

21

43 5

Connector on rear of sensor

1 (Brown) +11 to 28VDC

NPN Output

150mA max.

PNP Output

150mA max.

Ground

Polarity Invert

2 (White)

3 (Blue)

5 (Gray)

NPN Load

PNP Load

4 (Black)