Liquid Controls CENTRILOGiQ LCR.iQ Manual instruction

Other manuals for CENTRILOGiQ LCR.iQ

1

Table of contents

Other Liquid Controls Measuring Instrument manuals

Liquid Controls

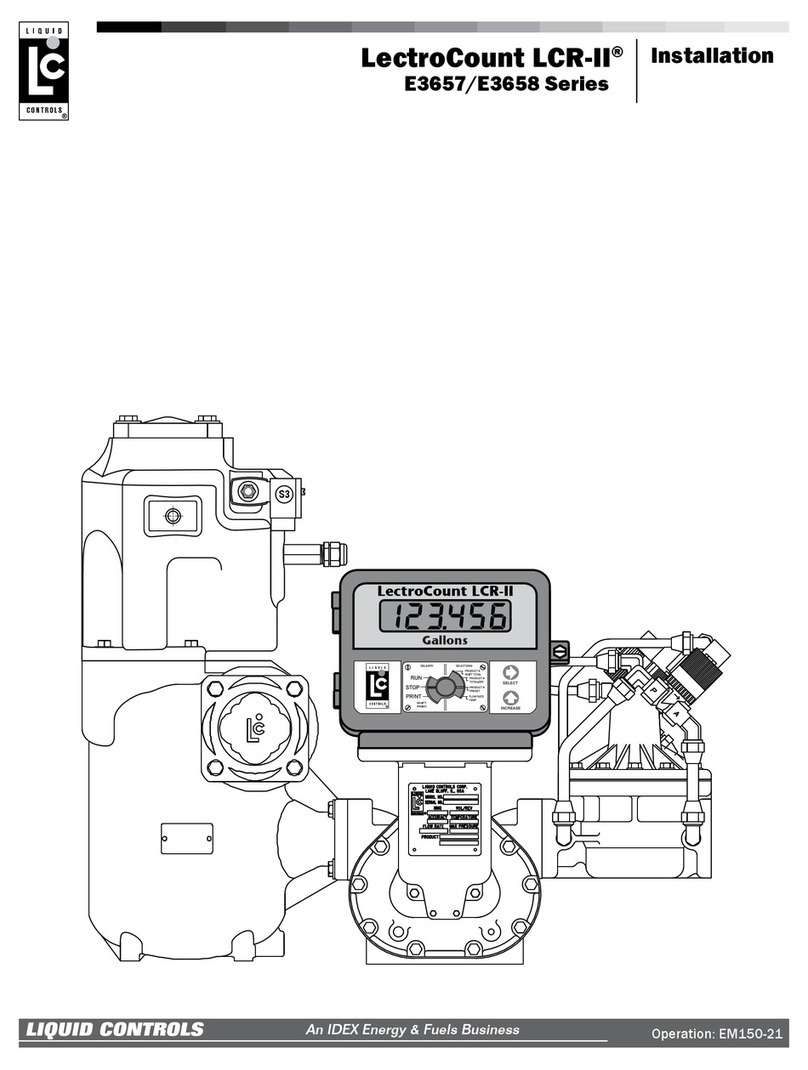

Liquid Controls LectroCount LCR-II E3655 Series User manual

Liquid Controls

Liquid Controls A8981 User manual

Liquid Controls

Liquid Controls Avery-Hardoll BM Series User manual

Liquid Controls

Liquid Controls M Series User manual

Liquid Controls

Liquid Controls LectroCount LCR-II E3657 Series User manual

Liquid Controls

Liquid Controls LectroCount3 Reference guide

Liquid Controls

Liquid Controls M Series User manual

Liquid Controls

Liquid Controls MS Series User manual

Liquid Controls

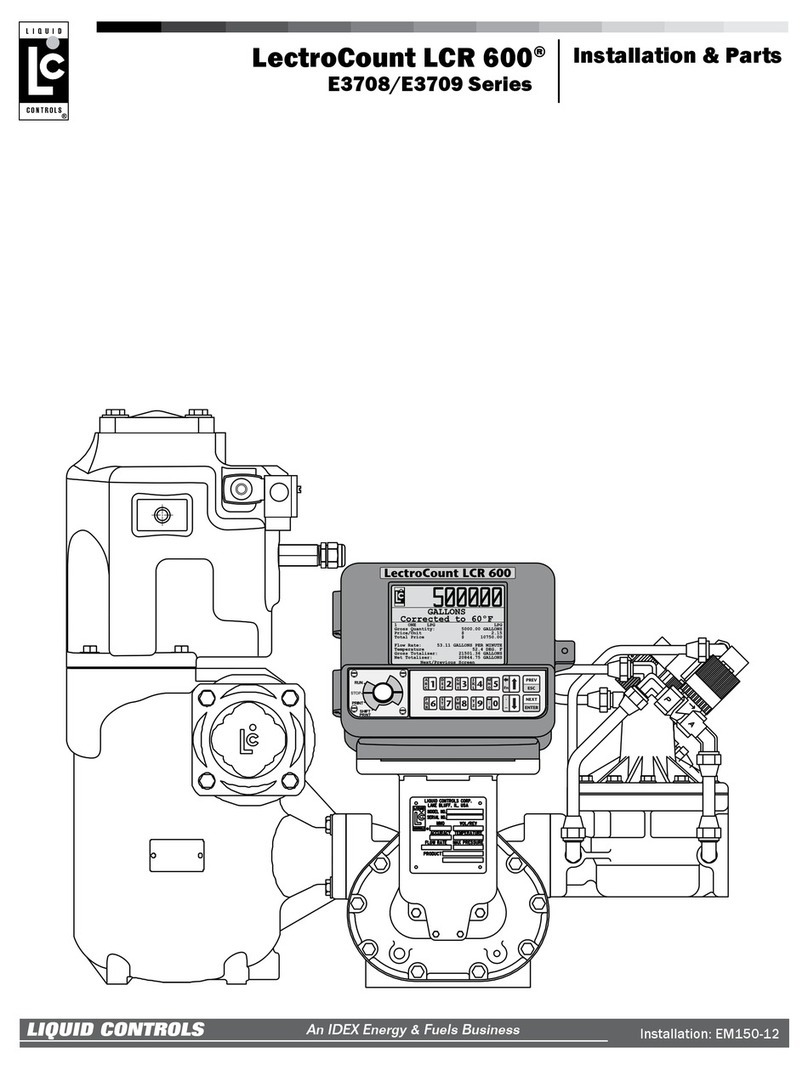

Liquid Controls LectroCount LCR 600 User manual

Liquid Controls

Liquid Controls LectroCount LCR 600 E3708 Series User manual

Popular Measuring Instrument manuals by other brands

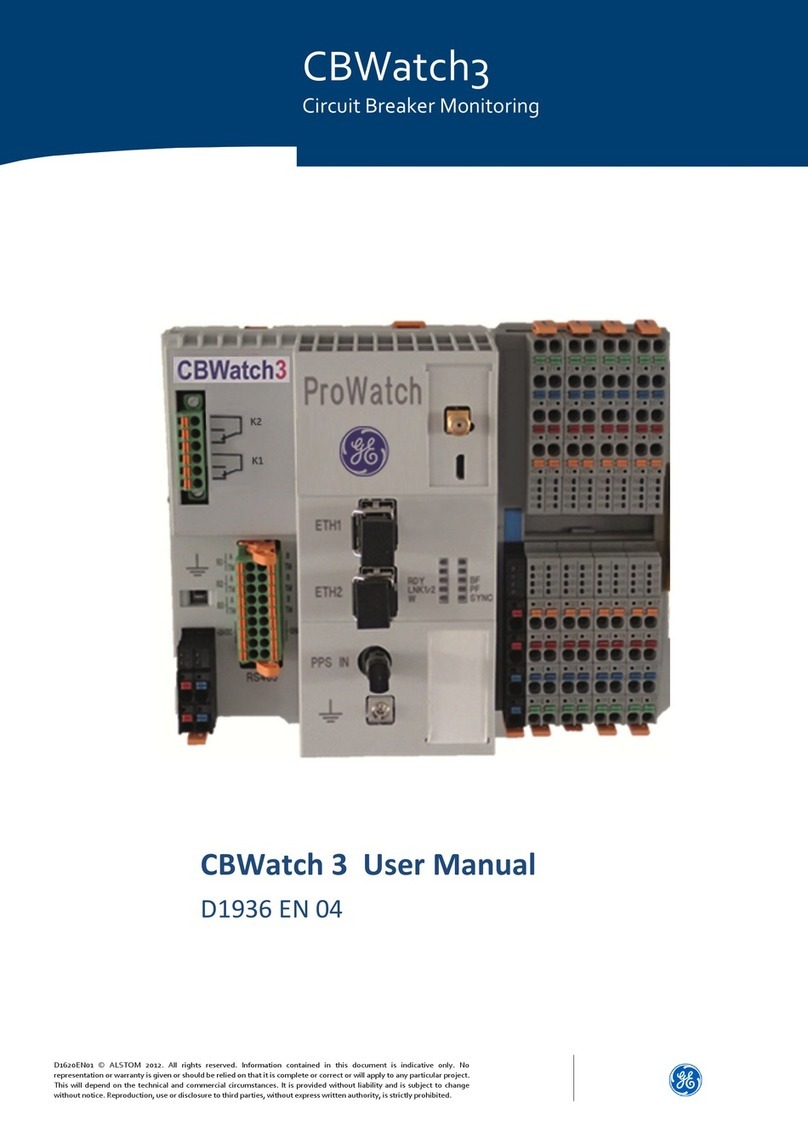

Alstom

Alstom CBWatch3 user manual

Endress+Hauser

Endress+Hauser Liquiline System CA80AM Brief operating instructions

Seres OL

Seres OL TOC User and maintenance manual

AccuEnergy

AccuEnergy AcuRev 1310 Series user manual

Masimo

Masimo PRONTO-7 Operator's manual

Renishaw

Renishaw SP600 Installation and user guide

Ivoclar Vivadent

Ivoclar Vivadent bluephase operating instructions

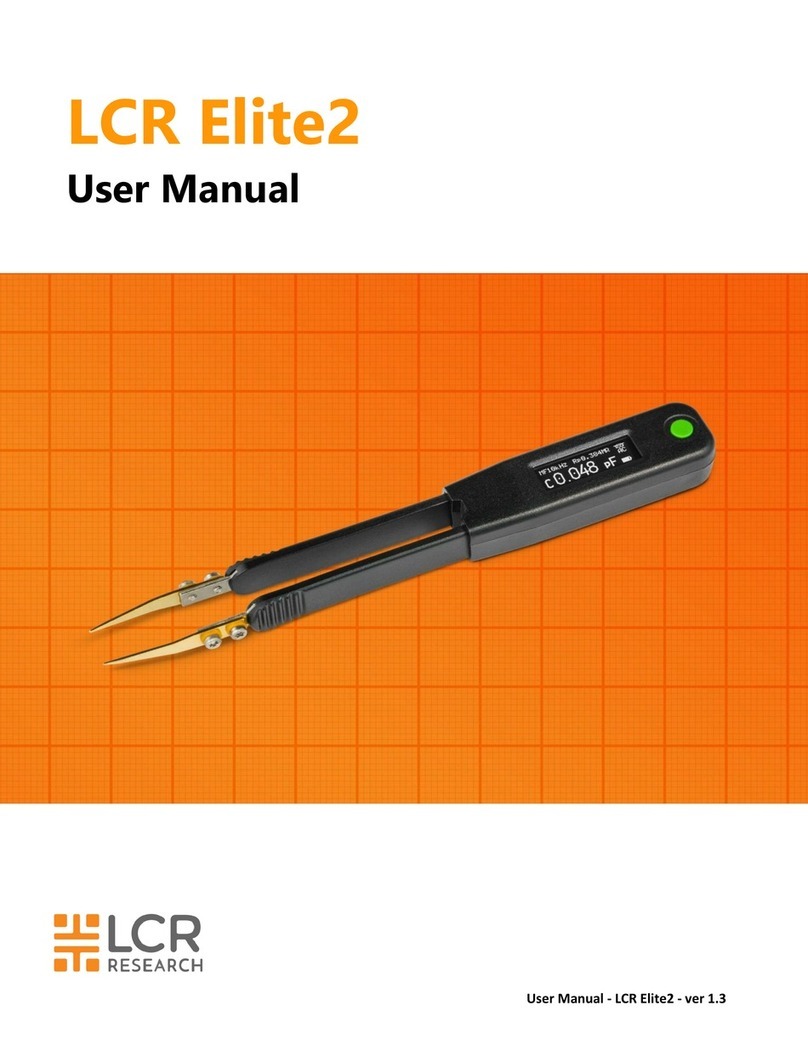

LCR

LCR Elite2 user manual

ITRON

ITRON CCU 100 installation guide

Sinar Technology

Sinar Technology 6095 AgriPro Operator's manual

Danaher

Danaher Hengstler tico 734 operating instructions

DAKOTA ULTRASONICS

DAKOTA ULTRASONICS MMX-7 Operation manual