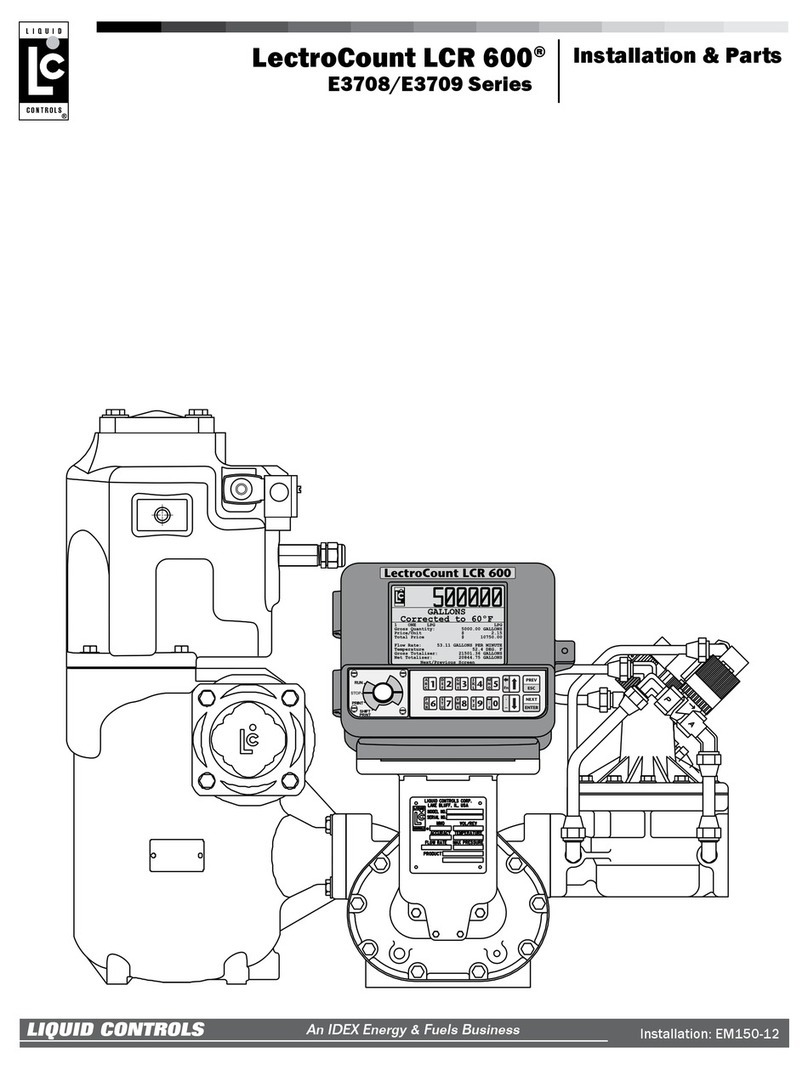

Liquid Controls LectroCount LCR 600 User manual

Table of contents

Other Liquid Controls Measuring Instrument manuals

Liquid Controls

Liquid Controls LectroCount LCR 600 E3708 Series User manual

Liquid Controls

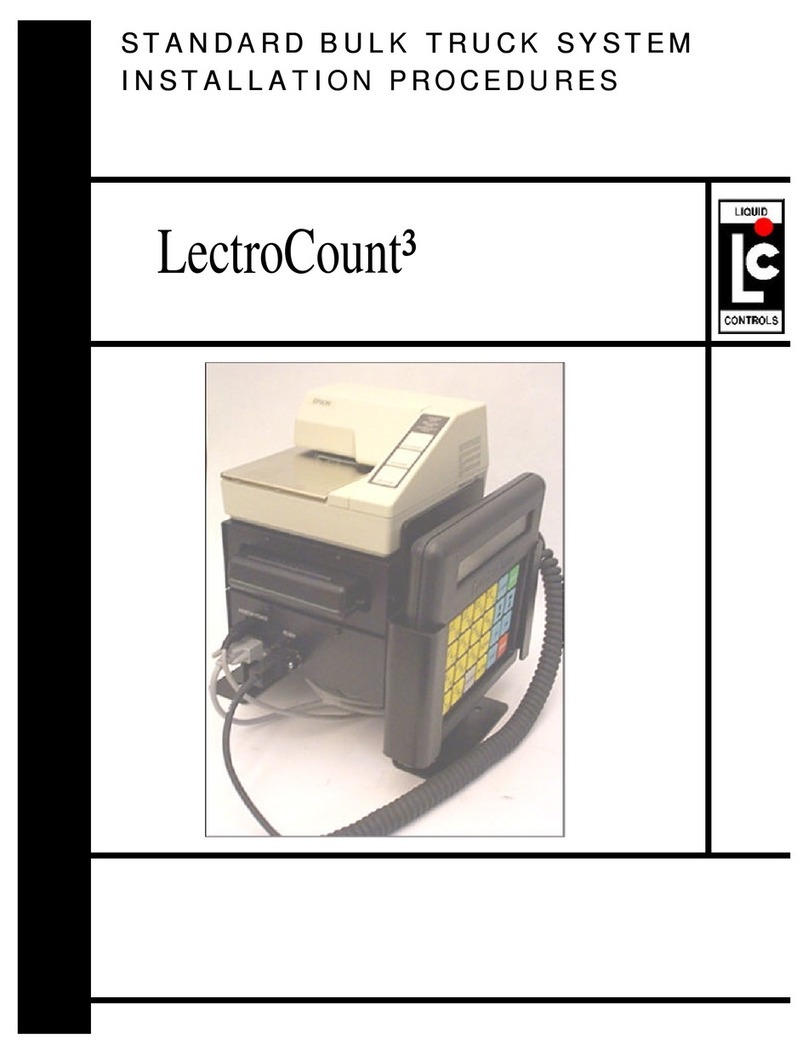

Liquid Controls LectroCount3 Reference guide

Liquid Controls

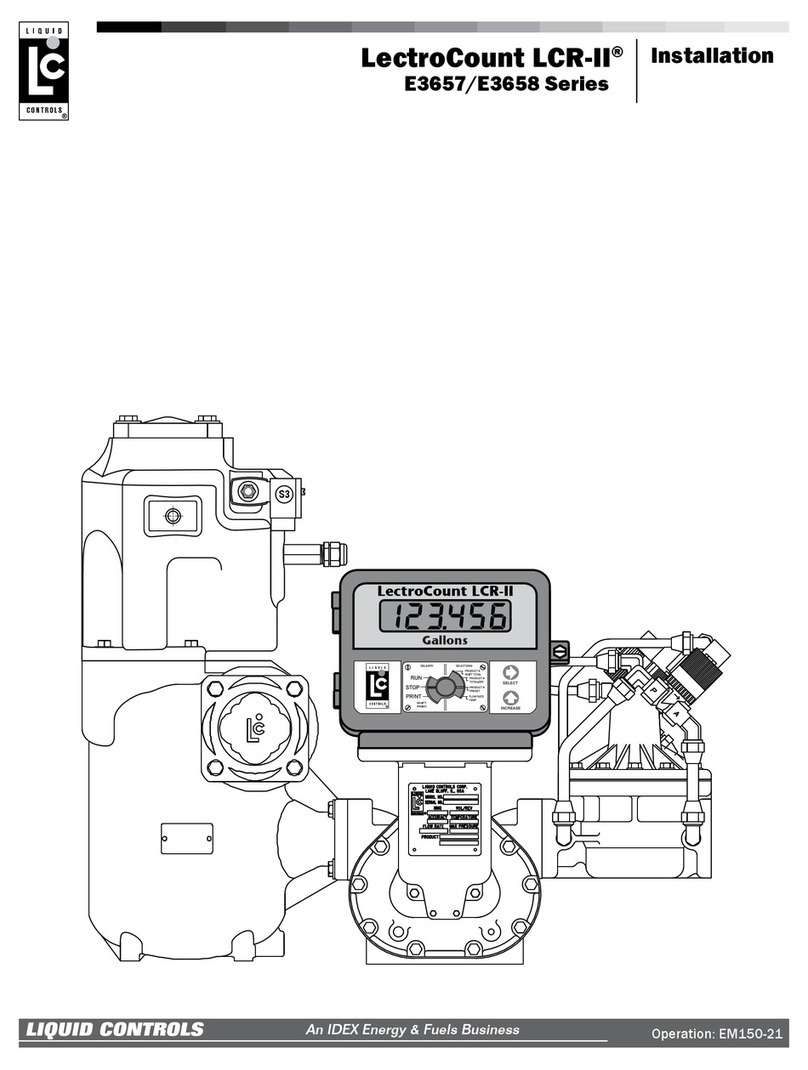

Liquid Controls LectroCount LCR-II E3655 Series User manual

Liquid Controls

Liquid Controls A8981 User manual

Liquid Controls

Liquid Controls MS Series User manual

Liquid Controls

Liquid Controls LectroCount LCR-II E3657 Series User manual

Liquid Controls

Liquid Controls CENTRILOGiQ LCR.iQ Manual instruction

Liquid Controls

Liquid Controls Avery-Hardoll BM Series User manual

Liquid Controls

Liquid Controls M Series User manual

Liquid Controls

Liquid Controls M Series User manual

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics HT352A25/NC Installation and operating manual

Ambco

Ambco 1000+P user manual

VeEX

VeEX FX80 user manual

Endress+Hauser

Endress+Hauser Silometer FMC 672 Z Installation and operating instructions

Sonel

Sonel MIC-2501 operating manual

Omega Engineering

Omega Engineering DPG104 instruction sheet

Omega

Omega FTB-4000 Series Operator's manual

Pyxis

Pyxis SP-395T user manual

Agilent Technologies

Agilent Technologies Agilent E6474A Configuration guide

Endress+Hauser

Endress+Hauser analytikjena Biometra TOne operating manual

Fluke

Fluke 700P2X Series instruction sheet

Pulsar

Pulsar SLUDGE FINDER 2 instruction manual